MIG Welding: A Game-Changer in Manufacturing

Understanding how MIG welding revolutionizes manufacturing processes with high efficiency, versatility, and automation.

Mechanical Engineer with specialization in industrial maintenance. 43 years of experience in the oil, petrochemical, gas, metalworking and food industries. Content developer, expert analyst in equipment and corrosion inspection and plant shutdown technical management. Qualified and certified in non-destructive testing techniques UT, PT, VT, MT, RT.

Understanding how MIG welding revolutionizes manufacturing processes with high efficiency, versatility, and automation.

Analyze lap welding, describing its fundamentals, techniques, characteristics and industrial applications.

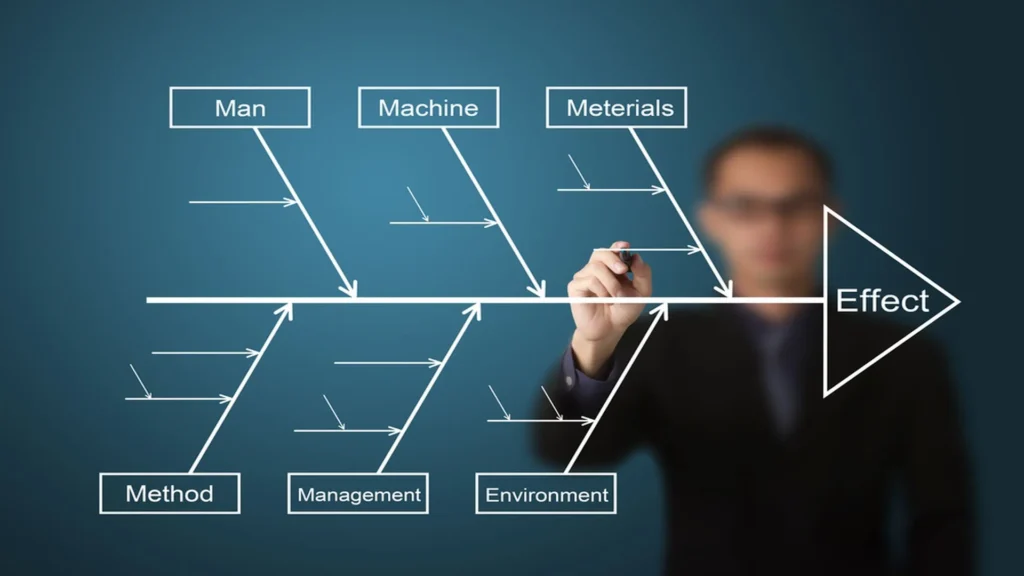

Discover how to build effective teams to perform Root Cause Analysis (RCA) and improve troubleshooting in your organization.

Advancing welding inspection techniques to enhance quality and safety.

Safety and efficiency in hydrocarbon storage tank terminals.

Ensuring operational integrity and safety through hydrostatic pipelines testing.

Discover how evaluation improves the efficiency and safety of process furnaces.

Structural analysis of springs: key to safe and efficient port operations.

Key criteria for designing hoses for the safe transport of liquid hydrocarbons.

Comparison between ecological inhibitors vs. traditional for sustainable solutions.

Examination of API Q1 and Q2 standards and how they drive process improvement, risk management, and operational efficiency in industrial systems.

Formation of iron sulfides and hydrogen sulfide as critical causes of degradation in hydrodesulfurization units.