Introduction

One of the most used methods in corrosion control is the use of chemical inhibitors; however, due to their chemical toxicity, other more sustainable alternatives are being developed such as the synthesis of ecological inhibitors. Currently, studies are being carried out to compare the effectiveness of ecological inhibitors vs. the traditional ones, in the fight against corrosion, being important for sustainable solutions.

These investigations will identify the most effective and environmentally friendly inhibitor systems to combat corrosion in various industrial applications. Metal corrosion affects the durability and reliability of infrastructure and industrial equipment, with chemical inhibitors being a practical solution, but with environmental implications due to their toxicity. The development and evaluation of green inhibitors is essential to address this problem.

Chemical inhibitors are toxic and difficult to break down, contributing to environmental pollution and the accumulation of toxic waste. The alternative to this product is the use of ecological inhibitors, designed to mitigate corrosion without sacrificing the environment. It has been proven that these inhibitors, derived from natural sources, not only reduce the environmental impact, but also reduce the corrosion rate of metals 1,2 , contributing to preserving the useful life of industrial assets. The transition towards greener solutions requires ensuring that these new inhibitors can offer performance comparable to their traditional counterparts, as well as their economic viability on an industrial scale.

This article performs a comparative analysis of ecological inhibitors vs. traditional inhibitors in terms of effectiveness in preventing corrosion, environmental impact and sustainability, as well as associated costs.

What are corrosion inhibitors?

Corrosion inhibitors are the conventional method of corrosion control; they consist of chemical substances that are added to a medium to prevent or slow the rate of corrosion in metals. These compounds act by forming a protective passive layer on the surface of the material, which significantly reduces direct contact between the metal and corrosive agents, such as oxygen, water, acids, or bases.

The effectiveness of a corrosion inhibitor depends on several factors, such as the composition of the medium, the nature of the metal, the concentration of the inhibitor and the operating conditions (temperature and pressure, among others).

Traditional corrosion inhibitors can be classified into several types according to their mechanism of action:

- Anodic inhibitors: These inhibitors act by forming a protective layer on the surface of the anode, which reduces the oxidation reaction. They usually contain ions such as chromates, nitrates, and phosphates.

- Cathodic inhibitors: They work by reducing the reaction at the cathode by precipitating insoluble compounds on the cathode surface, such as carbonates and sulfates.

- Mixed inhibitors: These inhibitors protect both the anode and the cathode. They contain molecules with functional groups that can adsorb on metal surfaces, forming a physical barrier.

- Volatile inhibitors: These are usually ammonia or amines, which evaporate and condense on the metal surface to form a protective layer.

Mechanisms of action in traditional corrosion inhibitors

- Adsorption: Inhibitors can be physically or chemically adsorbed on the metal surface, forming a protective film that prevents corrosion.

- Passivation: Some inhibitors promote the formation of a passive layer on the metal, which is less reactive and resistant to corrosion.

- Precipitate formation: Cathodic inhibitors typically reduce activity at the cathode by forming insoluble precipitates that protect the metal surface.

Advantages and disadvantages of traditional inhibitors

Among the most notable advantages we can mention the following:

- Efficient protection: They can offer effective protection against corrosion when selected and applied correctly.

- Versatility: There is a wide range of inhibitors available for different types of corrosive media and metals.

- Cost-effectiveness: Its use can be more economical compared to other corrosion protection methods.

Below are some disadvantages:

- Limited effectiveness: Its effectiveness may decrease over time or in the presence of certain conditions, such as high temperatures or changes in the composition of the medium.

- Specific Selection: Selecting the correct inhibitor requires detailed knowledge of the system and operating conditions.

- Environmental impact: Some inhibitors, especially inorganic ones such as chromates, are toxic and can have negative impacts on the environment.

Traditional corrosion inhibitors offer a practical solution for corrosion management in various industrial applications. However, their selection and use must consider potential environmental impacts and occupational health and safety.

Ecological inhibitors in corrosion control

Green corrosion inhibitors , also known as green inhibitors, represent a class of compounds that seek to minimize the negative effects associated with traditional corrosion inhibitors, especially in terms of toxicity and environmental damage. These inhibitors are derived from natural sources and are biodegradable, making them safer for the environment and human health.

How are eco-friendly corrosion inhibitors derived?

Ecological inhibitors are mainly derived from plants, fruits, leaves, and natural extracts . These materials contain organic compounds, such as tannins, alkaloids, flavonoids, and essential oils, which act as corrosion inhibitors. The selection of these compounds is based on their availability, biodegradability, and effectiveness as anticorrosive agents. The extraction process of these compounds usually involves methods such as maceration, infusion, or distillation, followed by purification to obtain the desired inhibitor.

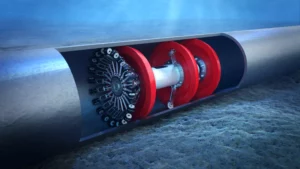

Oil and gas industry: In the oil and gas sector, corrosion inhibitors based on tannins, alkaloids and flavonoids can be added to fluids to prevent corrosion of equipment and pipelines. These inhibitors are especially valuable in acidic environments.

Mechanisms of action of green corrosion inhibitors

The mechanisms of action of ecological inhibitors are similar to those of their traditional counterparts, but with the advantage of being less toxic and safer for the environment. The main mechanisms include:

- Adsorption: The organic compounds present in green inhibitors adsorb on the metal surface, forming a barrier that reduces the electrochemical corrosion reaction.

- Film formation: Some compounds can react with metal ions to form a protective film on the metal surface, slowing the rate of corrosion.

- Passivation: Inhibitors can facilitate the formation of a passive layer on the metal, increasing its corrosion resistance in specific environments.

Advantages and disadvantages of eco-friendly corrosion inhibitors

Among the most notable advantages of these inhibitors are the following:

- Low environmental impact: Being derived from natural sources, they are more environmentally friendly compared to synthetic inhibitors.

- Safety: They are generally less toxic and safer for human handling, reducing health and safety risks in the workplace.

- Biodegradability: Its ability to decompose naturally minimizes the accumulation of toxic chemicals in the environment.

- Resource Availability: Many green inhibitors are derived from renewable and widely available resources.

Below are the most relevant disadvantages:

- Variability in effectiveness: The effectiveness of green inhibitors can vary significantly depending on the natural source from which they are derived, as well as the specific environment in which they are used.

- Stability: Some green inhibitors may be less stable under extreme temperature or pH conditions, limiting their applicability in certain industrial environments.

- Extraction cost: The process of extraction and purification of active compounds from natural sources can be expensive and technically challenging.

Eco-friendly corrosion inhibitors represent a promising alternative to traditional inhibitors, offering a more sustainable and safer solution for corrosion protection. However, its large-scale implementation still faces challenges related to standardization, production costs, and the need for additional research to optimize its effectiveness and application in different industries.

Comparative analysis of ecological inhibitors vs. traditional

In terms of their effectiveness in preventing corrosion in different metals and environmental conditions, and sustainability, it is essential to break down the comparison into several key aspects:

Effectiveness in preventing corrosion

- Ecological inhibitors: have shown effectiveness in preventing corrosion in various studies. However, its effectiveness can vary significantly depending on the type of metal, the environment (pH, temperature, presence of oxygen, etc.), and the concentration of the inhibitor. Some natural inhibitors, such as extracts of leaves, fruits, and other organic compounds, have been shown to be effective for metals such as steel, copper, and their alloys under specific conditions.

- Traditional inhibitors: Traditional inhibitors, such as phosphates, silicates, and chromates, have been widely used and studied, demonstrating high effectiveness in preventing corrosion in a wide range of environmental conditions and for various metals. However, its use is becoming increasingly restricted due to environmental and health concerns.

Environmental impact and sustainability

- Green inhibitors: Green inhibitors typically have a lower environmental footprint throughout their life cycle, from raw material sourcing to disposal, primarily due to their biodegradability and lower toxicity.

- Traditional inhibitors: Traditional inhibitors can have a greater environmental impact throughout their life cycle, especially if they contain heavy metals or toxic substances that can accumulate in the environment.

Toxicity

- Ecological inhibitors: Generally, they have lower toxicity to living organisms and are safer for human handling, which is a significant advantage in terms of occupational health and safety.

- Traditional Inhibitors: Toxicity is a major concern, especially with inhibitors that contain chromates and other heavy metals, which are highly toxic and carcinogenic.

Production and acquisition costs

- Green Inhibitors: The production of green inhibitors may involve higher upfront costs due to the research and development required to identify and extract effective compounds from natural sources. Furthermore, the extraction and purification process of these compounds can be more expensive compared to the synthesis of traditional chemical inhibitors. However, these costs may decrease as technologies and processes improve and production scales.

- Traditional inhibitors: Traditional inhibitors, being based on established synthetic chemical processes, can have lower production costs and be more economical in terms of large-scale production. However, increased regulation and the need for safe treatment and disposal of chemical byproducts can increase indirect costs.

Regulatory and compliance costs

- Green Inhibitors: Lower regulatory compliance costs due to reduced toxicity and environmental impact may make green inhibitors more attractive from a long-term cost perspective. Preference for “greener” products may also offer market advantages and government subsidies or incentives.

- Traditional Inhibitors: Compliance and safe handling costs, including toxic waste disposal, can be significant. Additionally, the risk of fines for environmental damage or regulatory violations can represent a significant indirect cost.

Brand image and consumer preference

The growing trend toward sustainability may make green inhibitors more desirable to consumers and companies seeking to improve their brand image, which could justify a premium price.

Conclusions

The comparison between ecological and traditional corrosion inhibitors reveals a complex picture where the choice depends on factors such as effectiveness, environmental impact, sustainability and costs. Green inhibitors, derived from natural sources, offer a promising alternative due to their biodegradability and lower toxicity. Although traditional ones are effective and economical, they raise environmental and health concerns due to their content of toxic substances and difficulty in degrading.

The transition towards greener and more sustainable inhibitors is not only desirable, but necessary to align industrial practices with sustainability and environmental protection goals. However, for this transition to be viable on a large scale, additional research is required to optimize the efficacy of green inhibitors, reduce associated costs, and overcome the technical challenges inherent in their production and application.

The choice between green and traditional inhibitors will need to balance corrosion prevention effectiveness, environmental impact, safety considerations and economic aspects, reflecting a conscious commitment to more sustainable and responsible industrial practices.

References

- Armaignac E, Hing Cortón R; “Study of ecological and natural inhibitors”; Chemical Technology, vol. XXVI, no. 3, September-December, 2006, pp. 48-58.

- Zariyen Agraje, Ismael Barahona, Joseph Quíroz, Héctor Pino, Cecilio Hernández , Casilda Saavedra ; “Comparative analysis of green inhibitors vs traditional inhibitors in metal corrosion”; ResearchGate, or questions or,Vol. 5- No. 2 · December · 2019.