Author: Ing, Ph.D. Yolanda Reyes, May 04, 2022.

Asset-intensive industries such as oil, gas, petrochemical, mining, metals, and power generation have been implementing new technologies in an effort to improve the reliability and availability of their equipment, without skyrocketing maintenance costs. . Using analytic software and advanced digital tools alongside traditional methods and techniques, these organizations aspire to predict and prevent equipment failures, increase workforce productivity, and streamline the management of their contractors.

When all requirements are met, the results can be surprising. In order to increase the productivity of maintenance work, leaders in heavy industries are now employing digital tools to significantly reduce unplanned downtime. Which, has produced increases in profitability in the order of 4 to 10 percent in some organizations.

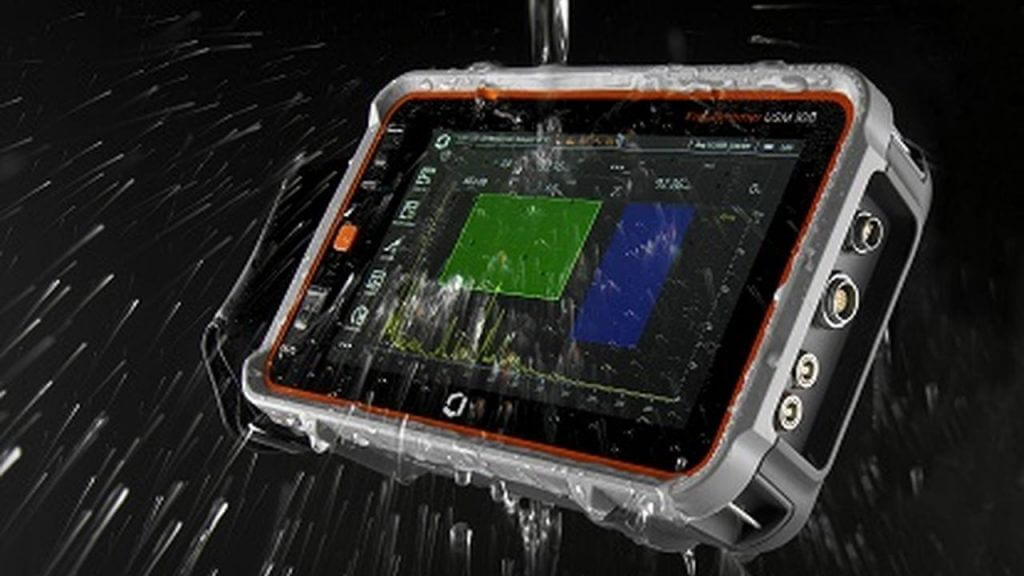

In this context, the company Waygate Technologies through its commercial representative the Testek Group, leaders in the manufacture and marketing of equipment and consumable materials for the maintenance and repair of underwater equipment and installations and everything related to these activities. world leaders in Non-Destructive Testing (NDT) solutions for industrial inspection, introduces the Krautkramer USM 100 , a portable Ultrasonic Testing (UT) device that takes repeatable ultrasonic inspections to the next level. In addition to UT capabilities, the Krautkramer USM 100 sets new standards in ergonomics, connectivity, and robustness, making it the go-to solution for users looking to increase overall efficiency in their inspections and quality control.

Krautkramer USM 100

The Krautkrämer USM 100 is a highly versatile, portable flaw detector with smartphone-like capabilities. Designed for ease of use, it features a large touch screen and buttons that allow for hassle-free training. Digital features include a best-in-class user interface that streamlines setup, training time and updates. It is the only fault detector on the market built for an interconnected world, offering the luxury of increased efficiency through remote access, data management and storage.

Krautkrämer USM 100 Highlights

ultrasonic excellence

The Krautkramer USM 100 amplifies the reliable ultrasonic capabilities already offered by the USM series, bringing accurate and repeatable inspections into a new era of flaw detection (Figure 1). Legacy USM Go+ and USM 36 datasets are compatible with this new model, allowing for a seamless transition into the future. Premium features include:

- Averaging – Removes noise signals by real-time averaging of A-scans.

- iOS App – Enrich your existing ultrasound data with images and geolocation information of test samples.

- Customizable Filter – Allows user-configurable filter settings.

- IF Gate / 3rd gate: IF gate allows interface echo tracking and maintains a consistent TOF measurement.

Easy to use

The USM 100 provides UT testers with unprecedented ease of use, respectful of the Krautkramer legacy, featuring a modern, intuitive interface with smartphone-like functionality, reducing the learning curve substantially. . The 7” high-resolution LCD screen is touchscreen, and can be used with gloves (Figure 1), under any weather and lighting conditions. Its low weight and the ability to switch between left or right handed operation further contribute to its well-balanced ergonomics.

Elegant and resistant design

In addition to ease of use, the USM 100’s state-of-the-art hardware design further increases its efficiency in everyday use:

Drop and vibration tested with an IP 67 rating, the USM 100 can be used in the toughest environments (Figure 3).

Its modern and intuitive user interface reduces training time. Picking up the device, even inexperienced operators can quickly become familiar with the device and its functions and it can be used for a wide spectrum of industrial inspection applications.

connectivity

The volume of inspection data is increasing at a much higher rate, so management and handling is a prerequisite for efficiency. Built for an interconnected world, the connectivity capabilities of the USM 100 include:

- Remote access and fleet management

- Secure, cloud-based data management

- Apps to customize your workflow

- Remote annual calibration to increase device uptime

Industrial Inspection Applications

Few inspection tools are more versatile than the portable Krautkrämer USM 100, built to tackle a wide variety of inspection challenges. Perform thorough and accurate inspections of industrial assets, enriching inspection data with images and geolocation to improve traceability and reporting.

welds

A variety of material requirements and inspection codes make welding inspection one of the most diverse and complex fields of inspection. The Krautkrämer USM 100 not only has excellent software and hardware capabilities for every type of weld inspection, it also features a guided inspection workflow for simple inspections and fast, consistent calibrations.

- DAC /TCG, AWS, DGS, JISDAC, CDNAC: Provide extensive defect sizing capability.

- 400% Amplitude Range – Prevents signal clipping while working with scan gain levels .

- ASME/AWS Applications – Provide a streamlined inspection workflow for code-compliant inspections.

- Color Stretch: For easy viewing of beam breaks.

Corrosion

Traditional access methods such as scaffolding, crane baskets and people lifts to inspect and detect corrosion problems are mainly due to the difficulty of accessing the work area; which increases the exposure of personnel to the risk of working under unsafe conditions. Under these conditions the Krautkrämer USM 100 represents a great alternative for use because of its low weight of only 1.2 kg (2.65 lbs.) and can be easily operated with one hand, and with the other you can manipulate the probe.

Railway Sector

When you’re always on the go, you need a detector that moves with you. Our customizable user interface makes it easy and simple to add and remove feature sets, which is ideal for tailoring your inspection workflow to railways.

- The square wave pulse generator allows for excellent acoustic penetration and signal to noise.

- Touch + button operation allows operation under all weather conditions.

- Application for geolocation.

conclusion

Testek represents a legacy built on reliability, a group pioneering industrial ultrasound technology for over 70 years. The Krautkrämer brand was built on a reputation for excellence – a testament to the confidence you can expect when using the products, knowing that every component is reliable and built to last. The Krautkrämer USM 100 carries this same DNA into the future, combining best-in-class detection displays with unrivaled connectivity. Unlocking the full potential of digital and analytics in maintenance and operations is no easy feat, but heavy industry leaders have reaped huge rewards for their efforts in this digital age.

Bibliographic references

https://www.testekndt.net/producto/deteccion-de-fallas-por-ultrasonido-usm-100/