Introduction

The Impact of Nanotechnology in Petroleum Refining represents one of the most promising and revolutionary advances in the energy industry. As the world looks for ways to optimize resources and improve industrial processes, nanotechnology emerges as a powerful solution, especially in petroleum refining.

This article explores how the incorporation of nanotechnology in petroleum refining is contributing to this sector, highlighting specific applications, benefits, and the future prospects of this fascinating technological intersection.

Background

Historically, petroleum refining has relied on technologies that have evolved little in terms of energy efficiency and environmental impact reduction. However, the rise of nanotechnology in recent decades has introduced unprecedented potential for innovation.

Currently, we are at a turning point where the application of nanotechnology in refining promises to solve critical challenges, including emission reduction, increased separation efficiency, and enhancement of the final product quality.

Key Concepts

Nanotechnology involves manipulating materials at an extremely small scale, generally between 1 and 100 nanometers. In this range, materials exhibit unique properties that can be leveraged to improve refining processes.

Nanofluids in petroleum refining, for example, are liquids that contain suspended nanoparticles and offer enhanced thermal properties, making them ideal for heat transfer. Nanoparticles, on the other hand, can act as highly efficient catalysts, improving the speed and selectivity of chemical reactions in the refining process.

Nanotechnology applications in the petroleum industry

The nanotechnology applications in the petroleum industry are varied and far-reaching. From improving refining processes to developing new nanomaterials to increase efficiency and safety, nanotechnology is paving new paths. One of the most notable applications is the use of nanofluids in petroleum refining.

In the context of petroleum refining, nanotechnology is used to enhance separation, conversion, and purification processes of crude oil into cleaner and more efficient products such as gasoline, diesel, and jet fuel. Some of the most important applications include:

- Improvement of catalysts: Nanotechnology allows for the design of more efficient catalysts at the molecular level. These catalysts can help break down or transform crude oil into its most valuable components more efficiently than traditional methods, saving time and resources.

- Advanced separation technologies: The use of nanomaterials in separation processes facilitates the more effective extraction of specific products from crude oil, improving the quality of the final product and reducing waste.

- Oil treatment and purification: Nanomaterials can absorb or react with impurities and unwanted substances present in crude oil, resulting in purer oil and higher-quality end products.

- Energy efficiency: The application of nanotechnology can reduce the amount of energy needed for refining, lowering operational costs and the environmental impact of oil production.

- Improving efficiency and reducing environmental impact: The implementation of nanotechnology in petroleum refining also has a significant impact on reducing environmental impact. More efficient processes mean less energy consumption and, therefore, a reduction in greenhouse gas emissions. Additionally, advanced purification techniques help eliminate harmful contaminants from fuels, contributing to a cleaner environment.

Example of application in everyday life

Imagine driving a car that uses gasoline as fuel. The Impact of Nanotechnology in Petroleum Refining can have a direct impact on your daily experience in several ways:

- Better fuel performance: Gasoline produced with advanced refining techniques can burn more efficiently in your car’s engine, offering you greater performance per liter. This means you can drive more kilometers with the same amount of gasoline, reducing the frequency with which you need to fill up the tank.

- Reduction of harmful emissions: By improving the quality of gasoline and other fuels, the emissions of harmful gases into the atmosphere decrease. This contributes to cleaner air and reducing the environmental impact of your vehicle.

- Reduced costs: In the long term, more efficient refining processes can lead to a reduction in fuel prices due to lower production and operation costs. This could translate into direct savings for you when paying for gasoline.

In summary, nanotechnology is improving the way petroleum is refined, leading to more efficient and clean fuels, benefiting both consumers and the environment. Although these changes may not be immediately visible in your day-to-day, their impact is reflected in the quality of the air we breathe, fuel costs, and the efficiency of our vehicles.

The science of nanotechnology is improving the way petroleum is refined, leading to more efficient and cleaner fuels, benefiting both consumers and the environment. Although these changes may not be immediately visible on a day-to-day basis, their impact is reflected in air quality, fuel costs and vehicle efficiency.

Prospects for nanotechnology in petroleum refining

Looking ahead, the prospects for nanotechnology in refining are extraordinarily promising. Continued research and development in nanotechnology is expected to lead to the creation of even more advanced nanomaterials and the optimization of existing processes. This could result in unprecedented efficiency and the production of next-generation fuels that are even cleaner and more sustainable. Some key areas of evolution and expectations in this dynamic field are highlighted below:

- Nanotechnology has begun to enable significant improvements in refining process efficiency, especially in catalysis and product separation. The development of more advanced and specific nanoparticles and nanomaterials is expected to continue improving these efficiencies, allowing for faster reactions, at lower temperatures and pressures, and with better selectivity toward desired products.

- The application of nanotechnology in the oil and gas industry is not only focused on efficiency and economy, but also on sustainability. Future advances are expected to allow for an even greater reduction in harmful emissions and resource use. For example, nanomaterials could play a crucial role in CO2 capture and storage or in the desulfurization of crude oil, significantly contributing to the mitigation of the environmental impact of refining.

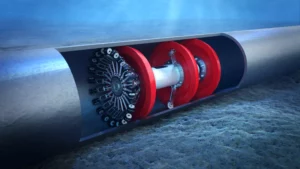

- Nanofluids and nanocatalysts represent two of the most promising applications of nanotechnology in petroleum refining. Future advances could include the development of nanofluids with even more improved properties for heat transfer or phase separation, and nanocatalysts with more specific and stable active sites, which could completely revolutionize traditional catalytic processes.

- Nanotechnology offers exciting possibilities for transforming refining residues into useful materials or energy sources through more efficient and sustainable processes. This valorization would not only decrease the environmental burden associated with waste but could also open new economic avenues for refineries.

Impact of nanotechnology on environment. (Video courtesy of: MGNK Physics Junction)

- With the advancement of nanotechnology in refining, there arises the need to develop specific regulations and standards that address both potential risks and safety and sustainability practices. Collaboration between industry, regulatory bodies, and the scientific community will be key to establishing a regulatory framework that facilitates innovation while protecting the environment and public health.

Conclusion

The Impact of Nanotechnology in Petroleum Refining is ushering in a new era in the energy industry. With applications ranging from improving efficiency to producing cleaner fuels, its benefits are clear and its potential vast. As we move towards a more sustainable future, the integration of nanotechnology in refining stands out as a promising path toward resource optimization and environmental impact reduction. The prospects of this technology are bright, and its ongoing evolution will surely play a key role in shaping the global energy landscape.

Explore the future of energy! Discover how nanotechnology is revolutionizing petroleum refining.