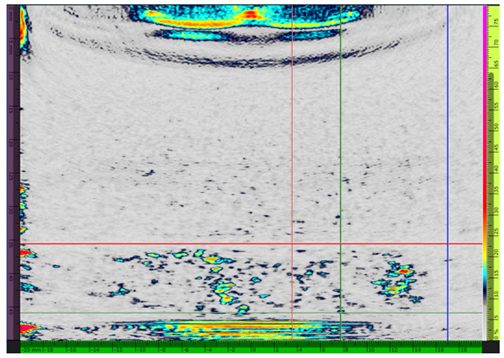

Advanced HTHA detection with PCI technology

The PCI technique allows the identification of HTHA damage in materials subjected to critical operating conditions.

The PCI technique allows the identification of HTHA damage in materials subjected to critical operating conditions.

Mechanical integrity in petroleum operations minimizes failures, enhances equipment reliability, and ensures compliance with safety regulations.

The vibration analysis allows to detect failures and optimize mechanical systems in sectors such as energy, aeronautics, industry and automotive.

Inspenet, October 24, 2023. In the world of industrial inspection, the constant search for innovative technologies that allow a more precise and efficient evaluation of materials…

Drones and robots are rapidly developing tools that transform inspections, providing access to remote and difficult areas, thereby lowering operational costs and significantly improving worker safety.

Learn how vibration analysis and the severity chart allow the diagnosis of mechanical failures in rotating machinery and the-optim interiores of industrial predictive maintenance.

Inspection equipment is currently being developed based on new technologies in the detection of faults and corrosion damage. In this context, the company Waygate Technologies, through…

Corrosion affects different types of metals that are used in various industrial plants, generating failures, defects and causing leaks. Few methods currently exist to detect these…

The company Waygate Technologies through its commercial representative the Testek Group, leaders in the manufacture and marketing of equipment and materials in non-destructive testing (NDT) solutions…

Storage tanks are equipment with infrequent maintenance periods, so they require continuous external inspections, to have a better control of their conditions during the time they…