High Temperature Hydrogen Attack (HTHA) represents a significant risk to industrial equipment operating in environments with high hydrogen content, especially in sectors such as petrochemicals and refining. Conventional assessment techniques often fail to accurately detect and characterize HTHA damage and are applied in combination for a higher probability of detection. However, recent advances in ultrasonic technology, particularly Phase Coherence Imaging (PCI), offer promising solutions to improve HTHA assessment.

What is High Temperature Hydrogen Attack (HTHA)?

Elevated temperature hydrogen attack is a failure mechanism generated in materials when subjected to high hydrogen pressures and elevated temperatures (at least 400 °F or 204 °C), resulting in thermal dissociation of the hydrogen molecule (H2) into hydrogen (H) atoms on the metal surface and its subsequent penetration into the interior of the metal. These atoms react with dissolved carbon to form methane gas CH4 (g) causing microstructural changes such as decarburization and carbide precipitation. This mechanism can be explained in three stages1:

- Stage 1: Methane trapped in the metal at grain boundaries, crystal structure imperfections, inclusions, or other discontinuities, forms a microscopic bubble.

- Stage 2: As the bubbles begin to grow, they begin to coalesce.

- Stage 3: Finally, the formation of these bubbles generates fissures and cracks1, compromising the integrity of equipment such as pressure vessels, piping and reactors, causing catastrophic failures if not detected in time.

The accumulation of bubbles creates microcracks at the grain boundaries of the steel, which reduce the strength of the metal and cause cracks to form in the steel, as shown in Figure 1.

Challenges in the evaluation of the HTHA

In its initial stages, high temperature hydrogen attack (HTHA) generally develops as micron-sized cracks in the material of a component under certain conditions such as: The presence of hydrogen molecules from the petrochemical with partial pressure in the mixture, high production temperature and the type of alloy or age of the component.

The early stages of HTHA present a challenge to inspectors using conventional ultrasonic testing (UT) techniques, as methane-related indications are typically smaller than the ultrasonic wavelengths employed. It is difficult to distinguish between HTHA, unusual grain sizes, inclusions, surface variations or geometry; a number of anomalies can often lead to false-positive results from an attack2.

While timely detection of HTHA is essential for the safe operation of petrochemical assets, the industry has been searching for effective and reliable ways to distinguish indications of manufacturing discontinuities such as microlaminations, inclusions or porosities.

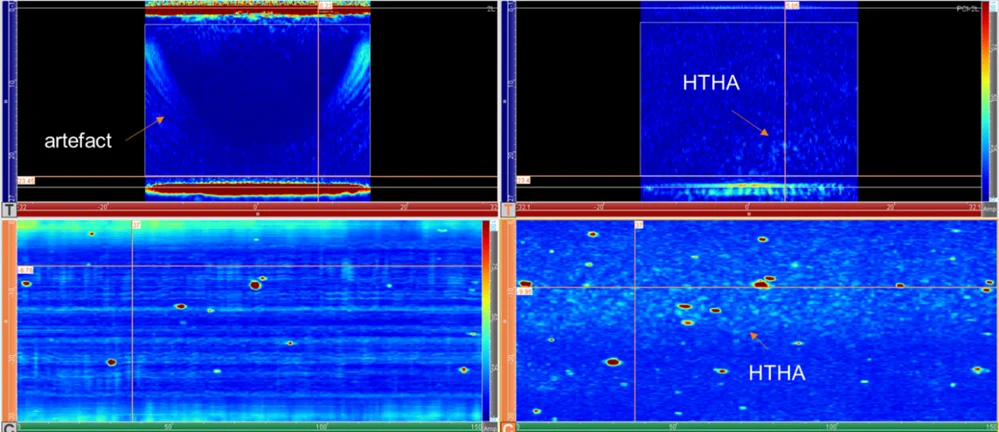

Practices such as API RP 941 mention the use of ultrasonic technologies, including Time of Flight Diffraction (TOFD), Phase Array Ultrasound (PAUT), Total Focusing Method (TFM), Advanced Ultrasonic Backscattering Technique (AUBT), among others, to detect possible HTHA damage and assess its condition; however, the use of these technologies in combination is recommended to obtain reliable results, since although each has its own strengths they also present their limitations.

Phase Coherence Imaging (PCI): Overview

Phase Coherence Imaging, or PCI, is a relatively new ultrasonic testing technique that complements TFM and addresses some of its limitations. PCI is based on the concept of preserving and utilizing the phase information of the received ultrasonic signals. By doing so, you can provide valuable information about the structure being inspected.

The received wave signals (each defining an A-Scan) are in phase when they have the same frequency, and the phase difference between them is constant.

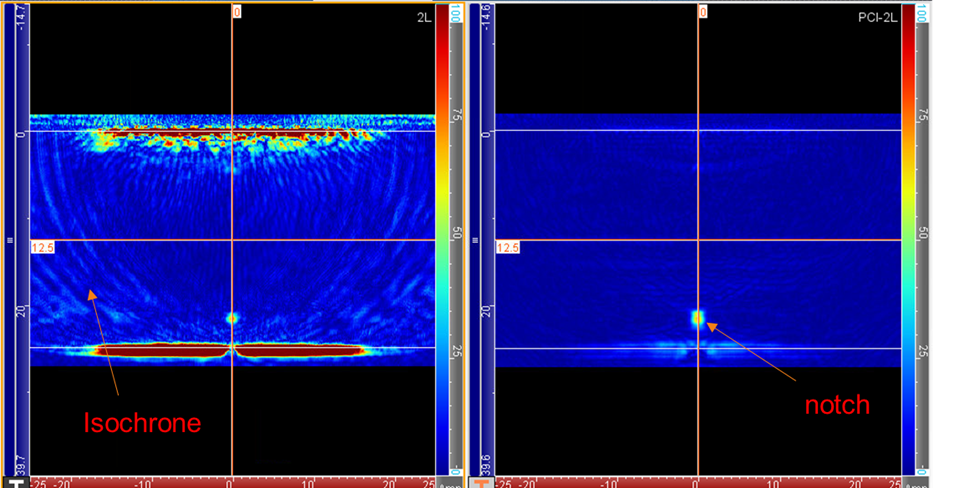

Thus, the processing of signals received via PCI is based exclusively on the phase information carried by the elementary A-scans used to generate a TFM representation and is independent of the amplitude of the A-scan indications (Figure 2).

Omnidirectional sources, such as porosities, pinpoint diffractions and slag, tend to show high intensity in the definition of the PCI indication, as many Full Matrix Capture (FMC) emitter-receiver pairs see them with approximately the same phase. Reflectors whose phase has a strong directional dependence, such as front surface, back wall, delaminations, lack of fusion (LOF), etc., produce low value PCI. PCI facilitates the detection of diffracted signals at the crack tip for better sizing, as well as those generated by cracking phenomena such as HTHA2.

HTHA detection via PCI

PCI has been developed and implemented in portable flaw detectors to help detect discontinuities that generate diffracted signals instead of reflections in ultrasonic tests using and taking advantage of the information provided by FMC/TFM.1It can thus differentiate coherent indications corresponding to high temperature hydrogen attack (HTHA) clearly from diffraction from those incoherent ones coming from specular discontinuities such as porosities and inclusions.

TFM is required beforehand to detect patterns of possible indications of high-temperature hydrogen attack (screening) which are subsequently ruled out or confirmed with PCI. Despite being two combined techniques, PCI has the advantage of being an addition that complements and integrates the TFM by taking advantage of the information from the latter, so that two different tests are not required.

In the case of porosities and inclusions, although they also produce diffractions, the difference lies in the fact that these types of faults also generate specular reflections, which when evaluated through PCI, it will be noticed that many of these will disappear from the screen, revealing them as volumetric.

Another technique that aids in better efficiency and sensitivity in HTHA assessment is PCI imaging from Planar Wave Imaging (PWI); such imaging represents a sector scan that uses the full aperture of the array, rather than scanning the entire element at once, combined with TFM reconstruction. The advantage is a gain in productivity and more sensitivity with an increased signal-to-noise ratio, the latter facilitating better definition of PCI indications (Figure 3).

Advantages of PCI in HTHA detection

- Live 2D imaging using signal phase information: This allows the identification of misoriented or very small defects, such as high temperature hydrogen attack (HTHA).

- Impossibility of signal saturation: This is not a problem for the PCI, since it is based on coherence and not on the amplitude of the signals.

- No gain manipulation required: In this technique, it is not necessary to adjust the gain to a known reflector (the gain control is locked to the instrument).

- Detection in noisy or attenuating materials: This allows detection of microcracks such as HTHA in austenitic microstructures and even better if combined with PWI.

- More consistent results and easier sizing: Results are repeatable between successive inspections, making it ideal for tracking in-service cracks and applying methodologies such as Fitness For Service.

- Quantitative analysis: PCI can quantify the extent and severity of HTHA damage, enabling accurate risk assessment and integrity management strategies.

Below is an informative video on phase coherence vs TFM vs PAUT in High Temperature Hydrogen Attack (HTHA) detection. Courtesy of: Shane Walton-University of Ultrasonics.

PCI Vs TFM Vs PAUT en la evaluación de daños por HTHA.

Conclusion

The ultrasonic Phase Coherent Imaging (PCI) technique represents a significant advance in the evaluation of High Temperature Hydrogen Attack (HTHA), providing high resolution imaging results through Non Destructive Testing, facilitating the detection, characterization and accurate monitoring of damage to industrial equipment under extreme conditions.

As research and development efforts advance innovation in inspection techniques, the safety, reliability and efficiency of industries related to processes involving hydrogen transport and where high-temperature corrosion phenomena may arise are ensured.

References

- FLORIN TURCU. Reducing False Calls in HTHA Inspection through Phase; Accessed February 06, 2024. https://www.ndt.net/article/ecndt2023/presentation/ECNDT2023_PRESENTATION_330.pdf

- FRÉDÉRIC REVERDY. Keep Your Cool with High Temperature Hydrogen Attack (HTHA) Cracking Assessments; Accessed March 07, 2024. https://blog.eddyfi.com/en/keep-your-cool-with-high-temperature-hydrogen-attack-htha-cracking-assessments