Table of Contents

- What is HTHA?

- Mechanism of high-temperature hydrogen attack

- Affected materials and risk factors

- Detection and inspection: Effective traditional techniques

- Challenges in ultrasonic detection of HTHA

- PCI: Advanced technology for ultrasonic detection of HTHA

- HTHA detection using PCI

- PCI technology: principle and advantages

- Operating benefits

- Integration with API 941 standard and Nelson curve

- Applicable rules and standards

- Prevention and mitigation strategies

- Industrial results and technical cases

- Conclusions

- References

- Frequently Asked Questions (FAQs)

- What is the difference between HTHA and hydrogen embrittlement?

- How does PCI technology work in practice?

- What are the advantages of PCI over PAUT or TOFD?

- On which materials is it most effective?

- How does PCI relate to API 941?

- What role does API 579 play in this context?

- Can PCI be applied to equipment in service?

- What resolution does it achieve in critical areas?

- What are the main limitations?

- What industrial benefits have been documented?

HTHA, or high temperature hydrogen attack, is a severe form of metallurgical degradation that affects steels exposed to hydrogen under extreme pressure and temperature conditions. This phenomenon generates methane in the microstructure, causing internal cracks that weaken process equipment.

In the energy and petrochemical industry, early detection of high-temperature hydrogen attack is a critical technical challenge. High-resolution ultrasonic technologies, such as Phase Coherence Imaging (PCI), enable the identification of incipient damage and improve operational reliability, in accordance with international standards such as API 941 and Nelson Curves.

What is HTHA?

High-temperature hydrogen attack is a metallurgical degradation phenomenon that occurs when hydrogen diffuses into steels exposed to high temperatures and pressures, reacting with the carbon in the base material. This reaction produces methane (CH₄), a gas that cannot diffuse through the metal structure and generates progressive internal pressure at the grain boundaries.

The result is the formation of intergranular microcracks, loss of ductility, and eventual catastrophic failure. Unlike hydrogen embrittlement or decarburization, high-temperature hydrogen attack occurs cumulatively, with no visible external signs until the damage is advanced.

In the refining and petrochemical industry, this mechanism affects reactors, heat exchangers, hydrogenation columns, and pipes operating above 400 °C (750 °F) and pressures above 3 MPa (435 psi).

Mechanism of high-temperature hydrogen attack

At the microstructural level, the process begins when atomic hydrogen penetrates the steel and reacts with carbides (Fe₃C) to form methane. This gas accumulates at the grain boundaries, generating localized pressure. This mechanism can be explained in three stages:

- Stage 1: Methane trapped in the metal at grain boundaries, imperfections in the crystal structure, inclusions, or other discontinuities forms a microscopic bubble.

- Stage 2: As the bubbles begin to grow, they start to merge.

- Stage 3: Finally, the formation of these bubbles generates fissures and cracks, compromising the integrity of equipment such as pressure vessels, pipes, and reactors, causing catastrophic failures if not detected in time.

The accumulation of bubbles creates microcracks at the boundaries of the steel grains, which reduce the strength of the metal and cause cracks to form in the steel, as can be seen in figure 1.

The damage process intensifies with:

- Steel composition (presence of Mo, Cr, or V).

- Hydrogen level in the process gas.

- Temperature and exposure time.

- Thermal cycles or frequent starts.

Carbon and Cr-Mo steels are the most susceptible. API 941 and Nelson Curves allow safe operating conditions to be established to prevent the progression of this attack.

Affected materials and risk factors

The materials most vulnerable to cracking are carbon and low-alloy steels, particularly Cr-Mo (1-1/4 Cr-1/2 Mo, 2-1/4 Cr-1Mo, 3 Cr-1 Mo). Resistance to hydrogen attack increases with chromium and molybdenum content, which reduce carbon activity and hydrogen diffusion.

Critical risk factors include:

- Operating temperature above 400 °C.

- High partial hydrogen pressure.

- Inappropriate chemical composition of the steel.

- Age of the equipment or thermal history.

Nelson Curves (API 941) allow safe operating conditions to be estimated. For example, 2-1/4 Cr-1 Mo steel has a safe service life up to approximately 425 °C at 10 MPa, while carbon steel exceeds the limit at only 350 °C.

Reference table

| Material | Safety limit (°C) | Pressure limit (MPa) | HTHA resistance |

| Carbon steel | 350 | 3.5 | Low |

| 1-1/4 Cr-1/2 Mo | 400 | 6 | Medium |

| 2-1/4 Cr-1 Mo | 425 | 10 | High |

Detection and inspection: Effective traditional techniques

Monitoring the cracking mechanism requires high-resolution non-destructive testing (NDT) methods. Among the most effective techniques are:

- TOFD (Time of Flight Diffraction): Uses wave diffraction to detect cracks at grain boundaries. Provides high accuracy in depth and size of indications, even in thick steels.

- PAUT (Phased Array Ultrasonic Testing): Provides multi-ring images and enables rapid volumetric inspections on large surfaces. Highly effective on pressure vessels and hydrogen pipes.

- TFM (Total Focusing Method): Based on complete digital reconstruction, it provides superior resolution for identifying early microcracks associated with the damage mechanism.

- AUBT (Advanced Ultrasonic Backscatter Technique): Detects subtle changes in the internal microstructure, differentiating affected areas from healthy ones. Ideal for predictive monitoring.

- FFS (Fitness for Service) Assessment: API 579 defines procedures for assessing components with signs of high-temperature hydrogen damage, determining whether they can remain in service or must be replaced. This approach is key to risk-based integrity (RBI) management.

- Wet fluorescent magnetic particles: The wet fluorescent magnetic particle (WFMT) method is a non-destructive testing technique that uses a magnetic field and fluorescent particles in suspension to detect surface cracks in ferromagnetic materials. In cases of HTHA, it is applied as a complementary inspection to identify surface cracks associated with advanced hydrogen damage.

Challenges in ultrasonic detection of HTHA

In its initial stages, high-temperature hydrogen attack manifests as imperceptible microcracks within the steel structure, influenced by the partial pressure of hydrogen, temperature, and material composition. These cracks, measuring one micron in size, are difficult to differentiate using conventional ultrasound due to their similarity to inclusions or metallurgical variations.

Although standards such as API RP 941 recommend techniques such as TOFD, PAUT, TFM, and AUBT, their ability to detect incipient damage is limited. In response, the industry has adopted advanced technologies such as Phase Coherence Imaging (PCI), capable of providing earlier and more reliable detection of high-temperature hydrogen attack.

PCI: Advanced technology for ultrasonic detection of HTHA

Phase Coherence Imaging (PCI) is a recent innovation in advanced ultrasonic testing (UT). It complements the Total Focusing Method (TFM), overcoming some of its limitations in identifying microdiscontinuities and incipient cracks.

Its fundamental principle is based on preserving and analyzing the phase information of the received ultrasonic signals, rather than focusing solely on their amplitude. This allows for a more accurate representation of the internal structure of the material, revealing areas affected by the attack phenomenon.

In practice, PCI processing utilizes the coherence between elementary A-Scans captured using the Full Matrix Capture (FMC) technique. When multiple transmitter-receiver pairs register waves in the same phase, the indications are reinforced and generate high-definition ultrasonic images.

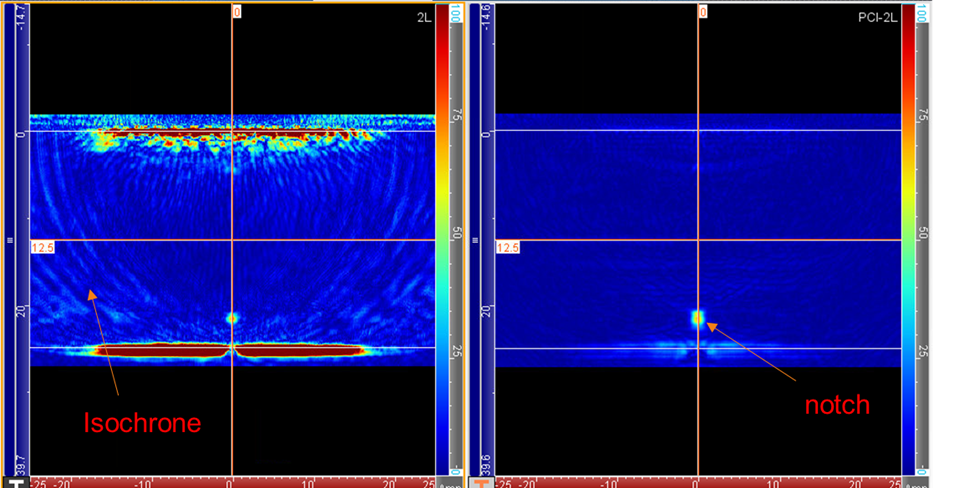

Thus, the processing of signals received via PCI is based exclusively on the phase information carried by the elementary A-scans used to generate a TFM representation and is independent of the amplitude of the A-scan indications (figure 2).

Omnidirectional sources, such as porosities or diffractions at crack tips, show high intensity in PCI images. In contrast, directional reflectors such as front surfaces or delaminations have lower values. This approach facilitates the accurate detection of microcracks or intergranular damage, achieving more reliable dimensioning and early detection of the degradation mechanism.

HTHA detection using PCI

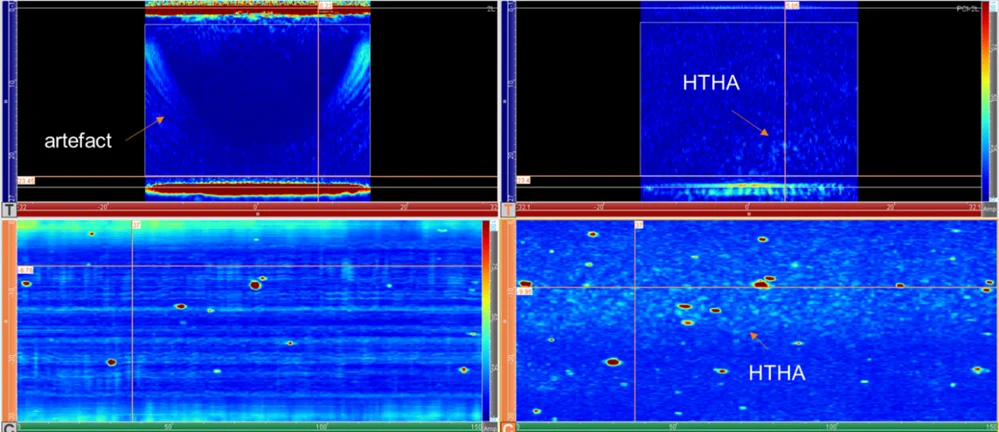

Phase Coherence Imaging (PCI) technology represents a significant advance in the detection of high-temperature hydrogen attack using advanced ultrasonic testing. This technology leverages the information generated by Full Matrix Capture (FMC) and Total Focusing Method (TFM) to differentiate diffracted signals characteristic of HTHA from those produced by volumetric defects such as porosities or inclusions.

Unlike other methods, PCI is integrated directly into the TFM process, without the need for additional testing. First, TFM ultrasound identifies patterns suspicious for HTHA (screening), which are then confirmed or ruled out by PCI analysis. This combination improves the accuracy and reliability of evaluating components exposed to high-temperature hydrogen.

In addition, the implementation of PCI images derived from Planar Wave Imaging (PWI) allows for sectoral scanning with greater sensitivity and a better signal-to-noise ratio, which increases definition and productivity in inspection. As a result, PCI has established itself as an effective tool for the early detection of HTHA, helping to prevent critical failures in process equipment (figure 3).

PCI technology: principle and advantages

Phase Coherence Imaging (PCI) is an advanced ultrasonic inspection technique developed to improve the detection of microstructural discontinuities associated with high-temperature hydrogen damage. Unlike conventional methods, PCI is based on the analysis of the phase coherence of waves reflected in the material.

Operating principles

- It evaluates the phase variation of the received acoustic signals.

- It generates coherence maps that allow microcracks and degraded areas to be visualized.

- It does not depend on signal amplitude, thus reducing false positives and improving accuracy.

Technology benefits

- Live 2D images using signal phase information: This allows poorly oriented or very small defects to be identified, such as high-temperature hydrogen attack.

- Impossibility of signal saturation: This is not a problem for PCI, as it is based on coherence rather than signal amplitude.

- No gain manipulation required: With this technique, it is not necessary to adjust the gain to a known reflector (the gain control is locked on the instrument).

- Detection in noisy or attenuating materials: This allows microcracks to be detected, such as high-temperature attack in austenitic microstructures, and is even more effective when combined with PWI.

- More consistent results and easier sizing: Results are repeatable between successive inspections, making it ideal for monitoring cracks that have developed and been detected during service and applying methodologies such as Fitness For Service.

- Quantitative analysis: PCI can quantify the extent and severity of damage, enabling accurate risk assessment and integrity management strategies.

- Greater sensitivity to microdamage than TOFD or PAUT.

- High spatial resolution and effective inspection depth.

- Detection capability in critical areas of Cr-Mo and carbon steels.

- Compatible with in-service inspections, integrating with RBI (Risk-Based Inspection) systems.

PCI is currently used to evaluate components subjected to hydrogen in refineries, ammonia plants, and hydrogenation units, where the risk of hot hydrogen attack is highest.

Operating benefits

Implementing inspections with PCI technology offers direct advantages for asset integrity:

- Early and predictive detection of degradation mechanisms.

- Quantitative assessment of damage severity.

- Reduction of downtime and unscheduled maintenance.

- Integration with risk-based inspection (RBI) programs.

- Extension of the service life of hydrogenation equipment.

- Alignment with API 941 and API 579 standards.

Overall, PCI enables a shift from a reactive to a proactive, evidence-based approach, where maintenance decisions are supported by objective data.

Below is an educational video courtesy of Acuren on the phenomenon of high-temperature hydrogen attack (HTHA) and its detection using advanced ultrasonic techniques such as TFM and PCI. This material illustrates the internal metallurgical mechanisms and highlights the importance of early detection to prevent catastrophic failures in industrial equipment.

Integration with API 941 standard and Nelson curve

API 941 is the main reference for material selection and operating limits in the presence of hydrogen. It establishes the Nelson Curves, which define the safe temperature and pressure ranges for each type of steel.

PCI technology complements this regulatory framework by providing empirical verification of the actual metallurgical condition. In this way:

- PCI inspections allow validation of whether a component operates within or outside the safe zone defined by API 941.

- The results can be integrated with FFS (Fitness for Service) analysis according to API 579, establishing quantitative damage criteria.

- This enables more accurate technical decisions regarding service continuity or equipment replacement.

An example of this activity is shown in figure 4, where a qualified and certified UT-PCI technician confirms whether the equipment operates within the safe zone of the Nelson Curves (API 941). The results are fed into an FFS (API 579) to decide whether to continue using or replace the equipment.

Thanks to this integration, plants achieve predictive management that combines theoretical models (Nelson curves) with real data obtained by advanced ultrasound.

Applicable rules and standards

The international standards governing the prevention and assessment of HTHA are:

- API 941 – Steels for Hydrogen Service at Elevated Temperatures and Pressures: establishes temperature and pressure limits using Nelson Curves, based on decades of industrial experience.

- API 579 / ASME FFS-1: guidance for fitness for service (FFS) analysis on components with hydrogen damage.

- ASME Section VIII: defines design and material requirements for equipment subject to high-pressure hydrogen.

These standards form the basis for structural integrity and predictive maintenance programs, especially in refineries, chemical plants, and hydrogenation units.

Prevention and mitigation strategies

Preventive measures include:

- Selection of resistant materials in accordance with API 941.

- Strict control of process temperature and pressure.

- Use of coatings or internal linings resistant to hydrogen diffusion:

- In critical equipment (reactors, hydrogen furnaces, or heat exchangers), Inconel 625 or Alloy 825 overlay is recommended in high-pressure and high-temperature areas.

- In areas exposed to wear or turbulent flow, ceramic coatings + metal overlay can be combined to achieve dual protection against hot hydrogen attack and erosion.

- Application of risk-based inspection (RBI) programs and periodic FFS evaluation.

- Training of technical personnel in degradation mechanisms due to hot hydrogen attack.

Proper design, combined with a predictive maintenance strategy, can significantly extend the service life of critical equipment and prevent major incidents.

Industrial results and technical cases

Case 1: The Anacortes Treasury Explosion

One of the most emblematic incidents of high-temperature hydrogen damage occurred at the Tesoro Anacortes refinery (Washington, USA, 2010). A carbon steel heat exchanger unit suddenly failed, causing an explosion that killed seven workers.

The CSB (Chemical Safety Board) investigation concluded that the equipment was operating above the limits set by API 941 and that adequate early detection inspections had not been performed.

This case prompted a review of Nelson curves and underscored the importance of risk-based periodic inspection programs combining advanced ultrasonic methods such as PAUT and TFM.

Case 2: PCI and TOFD comparison in a hydrogen reactor

At another petrochemical plant, both techniques were compared. TOFD only detected surface indications, while PCI revealed areas of microcracking at depth. This allowed the maintenance plan to be updated under an RBI scheme, reducing shutdown costs by 30%.

These results demonstrate that advanced detection with PCI improves the reliability of metallurgical diagnosis and extends the ability to predict hot hydrogen attack.

Conclusions

Advanced HTHA detection using PCI technology redefines inspection standards in hydrogen environments. Its ability to identify microcracks and early degradation provides a higher level of accuracy than traditional methods.

Integrated with API 941, API 579, and risk-based inspection programs, PCI drives the transition to predictive integrity management, strengthening industrial safety and the reliability of critical assets in the energy industry.

Don’t let HTHA compromise the reliability of your equipment!

This article is part of the editorial line of Inspenet, official media partner of global events such as GASTECH, API, AMPP, ASNT, SLOM, and others.

References

- FLORIN TURCU. Reducing False Calls in HTHA Inspection through Phase; Accessed on February 6, 2024. https://www.ndt.net/article/ecndt2023/presentation/ECNDT2023_PRESENTATION_330.pdf

- FRÉDÉRIC REVERDY. Keep Your Cool with High Temperature Hydrogen Attack (HTHA) Cracking Assessments; Accessed on March 7, 2024. https://blog.eddyfi.com/en/keep-your-cool-with-high-temperature-hydrogen-attack-htha-cracking-assessments

- CSB Safety Alert: Preventing High Temperature Hydrogen Attack (HTHA): https://www.csb.gov/assets/1/20/safety_alert_htha_final1.pdf?16371=&

Frequently Asked Questions (FAQs)

What is the difference between HTHA and hydrogen embrittlement?

High-temperature hydrogen attack occurs at high temperatures due to the reaction of hydrogen with carbon, while embrittlement occurs at low temperatures due to surface absorption.

How does PCI technology work in practice?

PCI analyzes the phase coherence of ultrasonic waves to detect microcracks that are invisible to conventional methods.

What are the advantages of PCI over PAUT or TOFD?

Offers higher resolution and sensitivity to microdamage, reducing false positives and improving metallurgical interpretation.

On which materials is it most effective?

In carbon and Cr-Mo steels used in reactors, exchangers, and hydrogen lines.

How does PCI relate to API 941?

It allows you to empirically validate whether a component is within the safe limits defined by Nelson Curves.

What role does API 579 play in this context?

Provides the FFS methodology for assessing the severity of detected damage and determining serviceability.

Can PCI be applied to equipment in service?

Yes, its application does not require disassembly, making it ideal for predictive inspections.

What resolution does it achieve in critical areas?

PCI can detect microcracks between 50 and 200 µm, exceeding the standard resolution of other techniques.

What are the main limitations?

Requires advanced calibration and highly specialized personnel in coherence data interpretation.

What industrial benefits have been documented?

Greater reliability in integrity assessment and up to 40% reduction in unplanned failures due to high-temperature cracking.