IRRSP Practical Examination Guide for Industrial Radiography

Training candidates for the IRRSP practical exam, ensuring their competence in radiological safety in industrial radiography.

Training candidates for the IRRSP practical exam, ensuring their competence in radiological safety in industrial radiography.

The standardization of NDT by ASME ensures reliable inspections, highlighting the importance of the code in the industry.

This article provides a detailed analysis of non-destructive testing on carbon and stainless steel.

The oil industry relies on NDT to maintain the integrity of equipment and structures, ensuring continuous operations.

Predictive maintenance reduces downtime and operating costs by anticipating failures through non-destructive analysis of equipment.

Examining the impact of Nondestructive Testing on equipment and pipeline service life.

Improve underwater subsea welding techniques for safer and more efficient infrastructure maintenance.

Application of NDT in the Foundry Industry: techniques, defects, properties, personnel selection and training.

Ensure quality and safety in the manufacture of pressure vessels.

Demonstrating how drone inspection improves efficiency and safety in the energy industry.

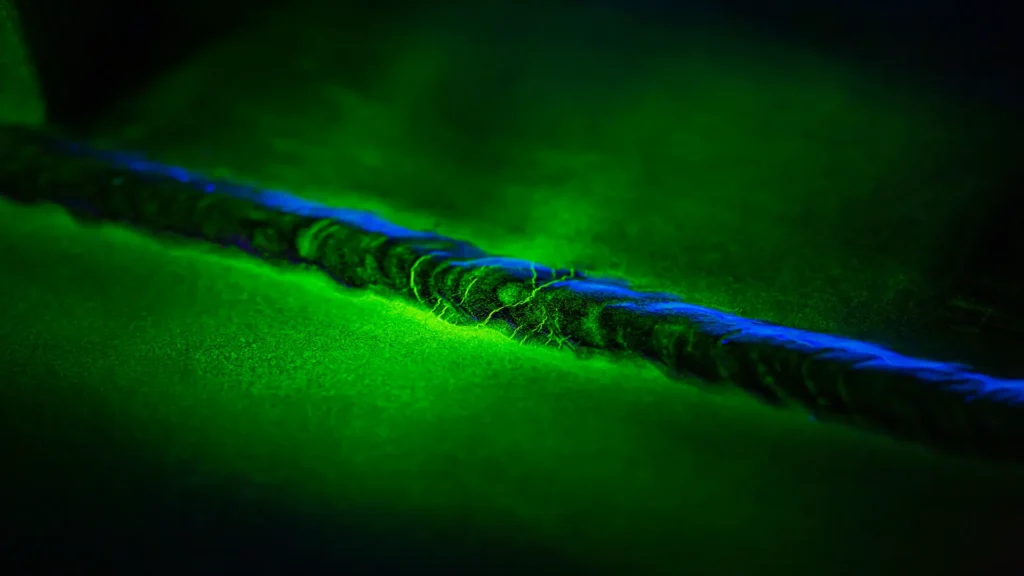

Detecting High Temperature Hydrogen Attack (HTHA) is most effective with wet fluorescent magnetic particles and magnetic flux.

The integration of automated NDT in Industry 4.0 enables real-time monitoring and improves predictive maintenance.