Challenges in the safe operation of fuel terminals

Liquid fuel storage presents significant environmental challenges that require attention and effective actions to mitigate their impact.

Liquid fuel storage presents significant environmental challenges that require attention and effective actions to mitigate their impact.

Explore how mining social responsibility regulates the relationship between extractive companies, communities, and environmental regulations.

We'll examine how a large portion of minerals end up in the trash and why opting for mineral recycling is essential.

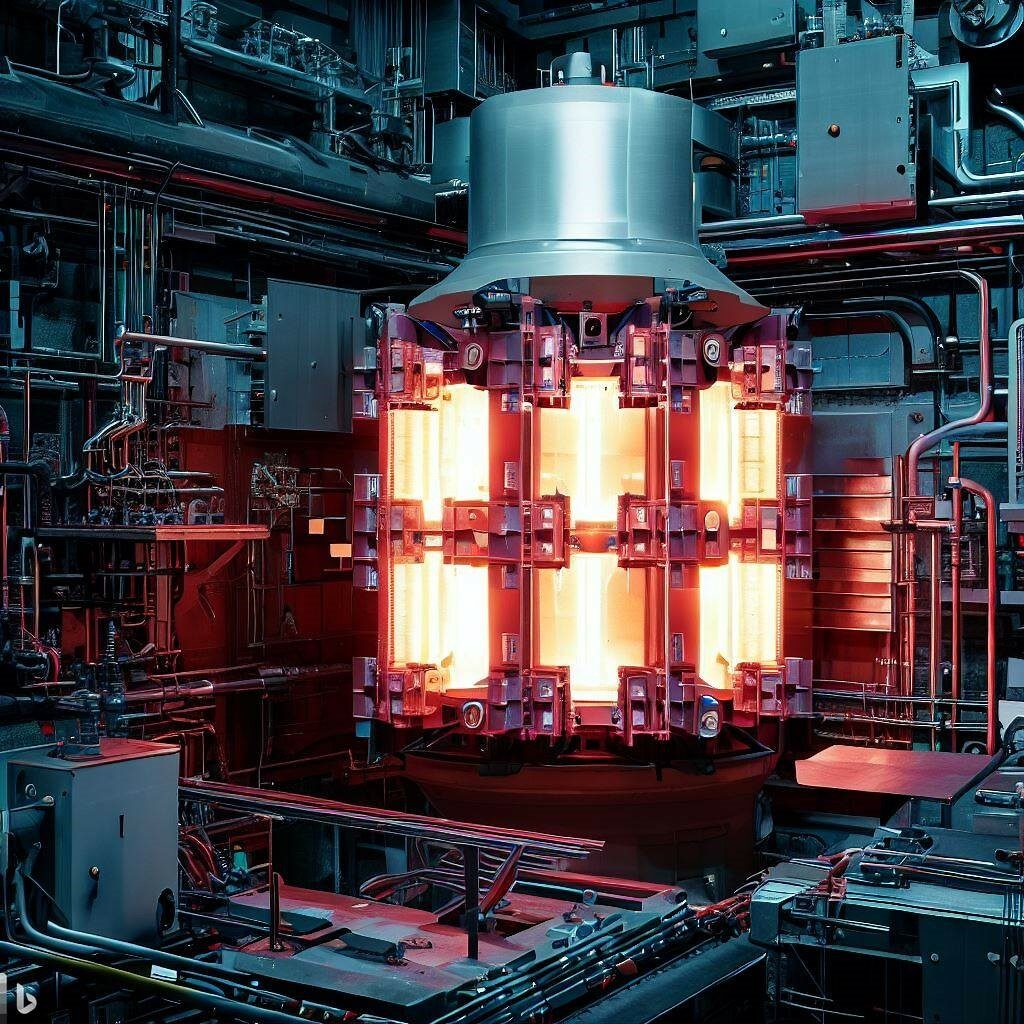

Analysis of Rolls-Royce's approach to implementing small modular reactors as a compact and scalable energy solution.

It was a manned underwater vehicle designed to conduct research and exploration expeditions in the deep sea.

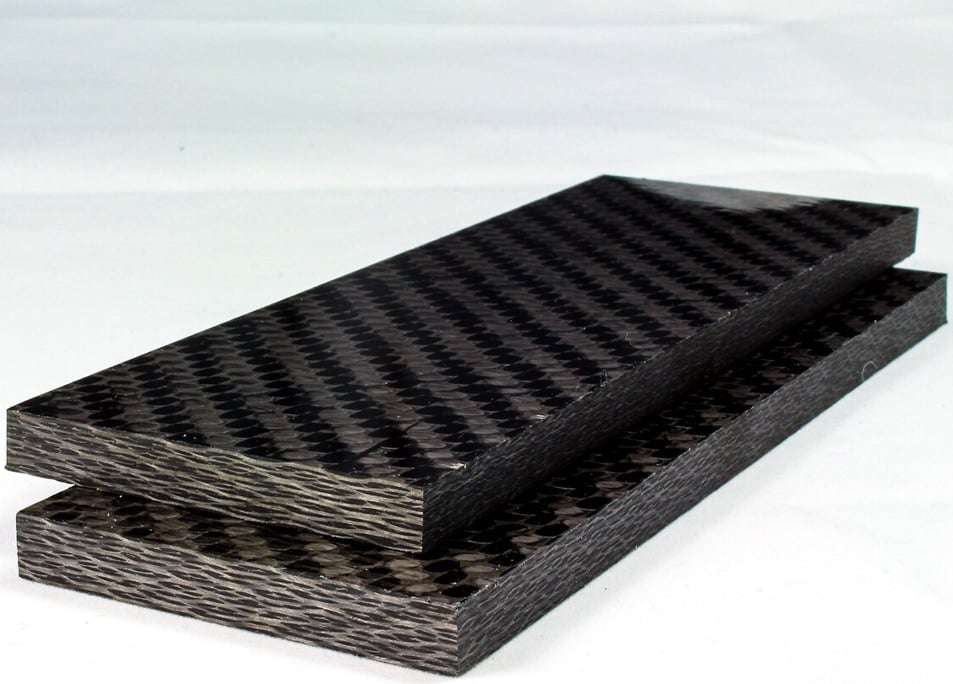

Discover the advanced alloy carbotanium, combining titanium and carbon fiber for revolutionary applications in aerospace, automotive, sports, and medical fields.

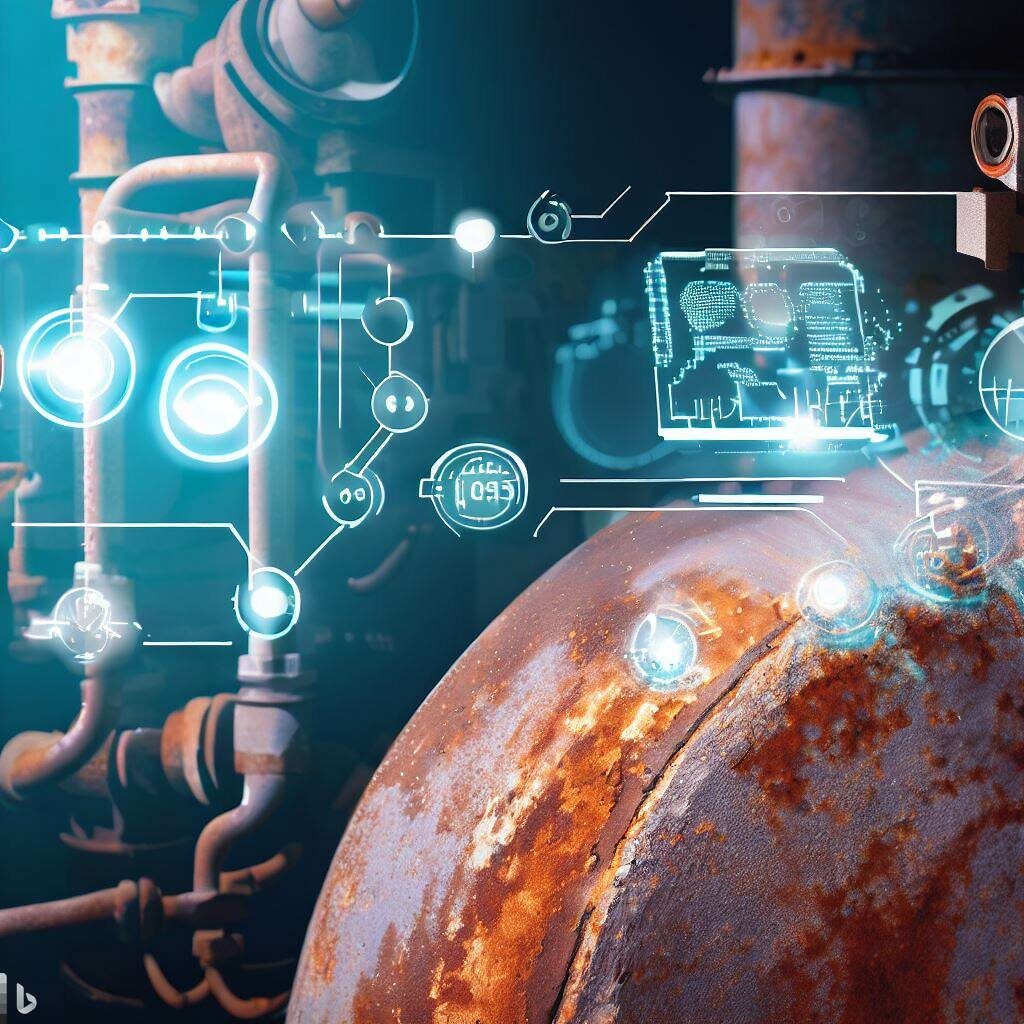

Impact of microbial activity on metals and structures in industrial environments.

The IoT allows corrosion to be detected and managed in real time using specialized sensors and continuous data transmission.

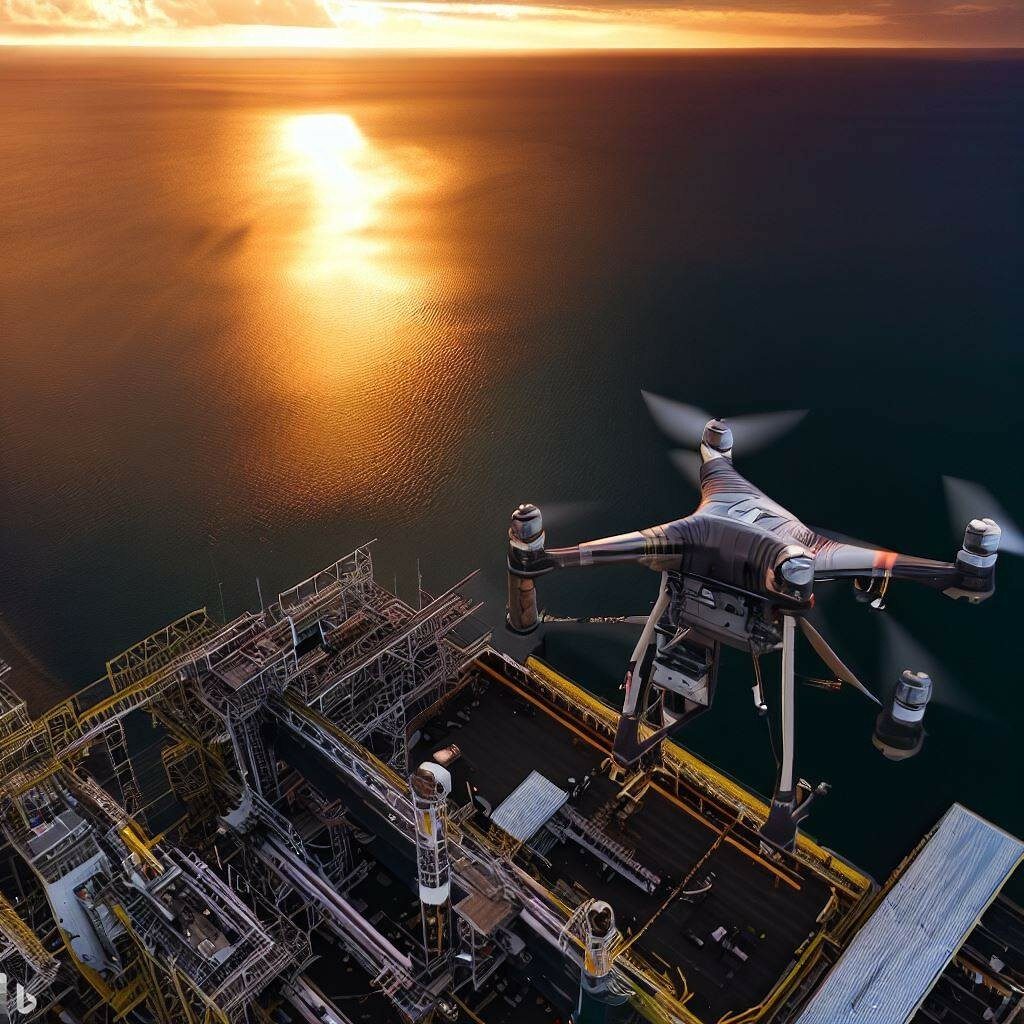

Drones and robots can detect corrosion in critical areas, improving precision and safety in industrial operations.

Types of renewable energy used in mining, their advantages, and how they are changing industrial processes.

Artificial intelligence boosts mine safety by identifying risks and improving training, facilitating faster and more accurate decisions.

Circularity requires redesigning processes to reduce waste and maximize value at each stage of the product life cycle.