Green nanotechnology has positioned itself as one of the most promising areas to address the pollution and waste challenges of the petrochemical industry. Over the years, this industry has been a significant source of negative environmental impacts. However, recently there has been an increase in research and development of sustainable and efficient solutions in this field.

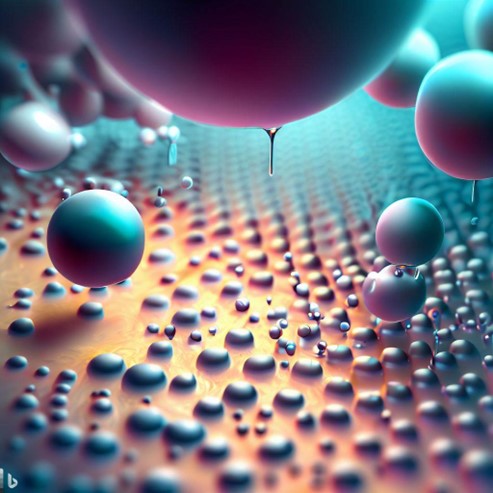

Nanoparticles , which are particles with dimensions in the nanometer scale (10^-9 meters) or equivalent to one billionth of a meter, are playing a crucial role in the transformation of the petrochemical industry towards greater sustainability.

The application of green nanotechnology represents a transformative vanguard. Through the responsible use of sustainable nanomaterials, this discipline offers innovative solutions to optimize the production of fuels and chemical products, reducing environmental impacts. The combination of efficient processes and environmentally friendly materials promises to revolutionize the industry in a more eco-friendly and efficient direction.

Application of green nanotechnology in petrochemicals

Nanoparticles have unique properties that make them ideal for use in industry, they have a variety of applications in the petrochemical industry . Their size allows them to interact with molecules at the atomic level, making them highly effective in improving the efficiency of chemical processes. In addition, their high surface-to-volume ratio allows them to have greater reactivity and reaction capacity, which makes them useful in the removal of contaminants and in improving the efficiency of catalysts .

It is important to highlight the adsorption capacity of these particles. Adsorption is a process in which molecules of one substance adhere to the surface of another substance. In the case of adsorption, it occurs when the molecules of a substance adhere to the surface of the nanoparticles. This process can be used in various applications, such as the removal of pollutants from wastewater, the improvement of the efficiency of catalysts and the capture of greenhouse gases.

- Improvement of the efficiency of catalysts: They are used to improve the efficiency of catalysts in the petrochemical industry, these are substances that accelerate chemical reactions without being consumed in the process. By using them as a support for the catalysts, the contact surface between the catalyst and the reactive substances can be increased, which increases the efficiency of the reaction. This makes it possible to reduce the amount of catalyst needed and lower production costs.

- Reduction of pollutants : They also apply to reduce the amount of waste generated in the industry. By improving the efficiency of chemical processes, the amount of unwanted by-products is reduced and the generation of waste is minimized. In addition, they can be used to remove contaminants from industrial effluents, which reduces the environmental impact of the industry.

- Resource optimization: They are being used to optimize the use of resources in the petrochemical industry. By improving the efficiency of chemical processes, the amount of raw materials needed for the production of petrochemicals is reduced. This allows to reduce production costs and minimize the environmental impact of the extraction of natural resources.

Challenges and future prospects in the petrochemical industry

Despite the advances in the application of nanoparticles, there are still challenges that need to be addressed. One of the main challenges is the lack of knowledge about the long-term effects on the environment and on human health. In addition, production can generate waste and pollutants such as chemical residues, unwanted particulates, greenhouse gases, airborne particulates, and wastewater that must be properly managed.

In the future, research and development in the field of nanotechnology is expected to continue to grow. It is expected that new, more sustainable and efficient production techniques will be developed, as well as new applications of these particles. In addition, it is expected that more studies will be carried out on the effects that they can cause in the environment and in human health, which will allow a better understanding of the risks and benefits associated with their use.

Large petrochemical companies are playing a critical role in the development and adoption of nanoparticle technologies in the industry. These companies have the necessary resources and infrastructure to carry out large-scale research and apply new technologies in their operations.

Some of the major petrochemical companies that are investing in the research and development of this technology include:

- ExxonMobil: This company has been investing in nanotechnology research to improve the efficiency of catalysts in the production of petrochemicals. They are also exploring its use to improve efficiency in oil and gas extraction.

- Shell: You have been doing research on using it to improve efficiencies in the production of petrochemicals and in oil and gas extraction. They are also investigating how to reduce the amount of waste generated in their operations.

- BP: This company has been investing in research to improve efficiency in the production of petrochemicals and in the extraction of oil and gas.

- Chevron: This company is researching to improve the efficiency in the production of petrochemical products and in the extraction of oil and gas through the use of these particles.

These companies are collaborating with universities and research centers to develop new technologies and applications in petrochemicals. In addition, they are implementing these technologies in their operations to improve efficiency, reduce environmental impact and optimize the use of resources.

Conclusion

Nanoparticles are playing a crucial role in the transformation of the petrochemical industry towards greater sustainability. However, there are still challenges that need to be addressed, such as the lack of knowledge about the long-term effects on the environment and on human health. In the future, research and development in the field of nanotechnology is expected to continue to grow, allowing for a greater understanding of the risks and benefits associated with its use and the development of new, more sustainable and efficient techniques and applications.