Table of Contents

- CO₂ capture and geological storage (CCS) process

- Well integrity in CO₂ storage

- Mechanical integrity tests before injecting CO₂

- Regulations applicable to CO₂ well monitoring

- Corrosion prevention in CO₂ injection wells

- Monitoring, reporting, and verification of CO₂ leaks

- Technical and regulatory challenges in well integrity

- Recommended best practices

- Conclusion

- References

- FAQs

The integrity of geological storage wells is an important aspect of the carbon capture and storage (CCS) value chain. These wells, which are often adapted from existing oil infrastructure or built specifically for this purpose, must meet strict criteria for safety, resistance, and continuous monitoring.

Geological storage of CO₂ is one of the most promising strategies in the fight against climate change. For this technology to be safe and reliable, it is essential to ensure the integrity of the wells used for injection and underground confinement.

This article explains what tests are performed before injection, how corrosion in tubing and casing can be prevented, and what monitoring techniques are implemented to ensure that there are no carbon dioxide leaks to the surface or aquifers. It also includes international best practices and recommendations for extending the useful life of wells.

CO₂ capture and geological storage (CCS) process

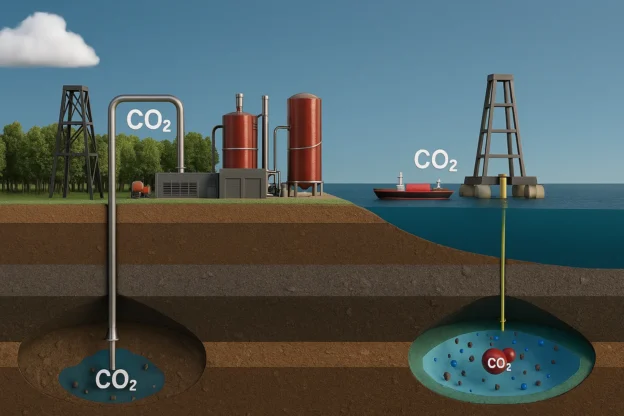

The following image shows a representative version of this process: carbon dioxide (CO₂), captured from industrial sources, can be injected into underground formations for storage or reuse. Four main methods are highlighted:

- Depleted oil and gas fields: Empty cavities are used to safely store CO₂.

- Enhanced oil and gas recovery (EOR): CO₂ is injected to increase pressure and extract residual hydrocarbons.

- Deep saline formations: Both onshore and offshore, carbon dioxide is stored in deep saline aquifers.

- Methane recovery from coal beds: At this stage, CO₂ displaces the methane trapped in the coal, facilitating its extraction.

This process not only reduces the carbon footprint, but can also optimize energy production in certain cases. If you like, I can explain each method in more detail or help you prepare a visual presentation. Would you like that?

Well integrity in CO₂ storage

Wells as a critical route for injection and containment

In carbon storage projects, wells are the infrastructure that connects the surface with the deep geological formation. Not only the efficiency of injection but also environmental safety depends on their integrity.

A well with deficiencies in cement, steel, or completion can become an escape route for CO₂ to unwanted formations or even to the surface. This compromises the viability of the project and can have regulatory, economic, and social consequences.

Main risks of integrity loss

- Leaks into underground aquifers that compromise drinking water resources.

- Migration of CO₂ to the surface, with environmental impact and health risks.

- Accelerated corrosion of tubing and casing, reducing the useful life of the well.

- Loss of cementation, weakening physical containment barriers.

In this context, maintaining integrity is an essential condition for public acceptance and certification of carbon credits under international regulations.

Mechanical integrity tests before injecting CO₂

Mechanical integrity tests (MIT) are performed before any injection begins. The objective is to verify that the well does not leak and that its primary and secondary barriers are functioning properly. The main tests include:

- Pressure testing on tubing and casing

- Controlled pressure is applied to confirm that there are no leaks in the pipe.

- Pressure drop is generally measured over a specific period.

- Cement integrity test (Cement Bond Log – CBL)

- Assesses the quality of the cement that seals the annular space between the casing and the formation.

- Defective cement can become a leak channel for CO₂.

- Injectivity tests

- These measure the well’s capacity to inject CO₂ without causing fractures in the formation.

- They include analysis of pressure, flow rate, and fracture gradient.

- Caliper logs

- These record the internal diameter of the pipe.

- They detect corrosion, ovalization, or deformations that compromise flow.

- Section isolation tests (Pressure Fall-Off Test)

- These evaluate the hydraulic communication between formations, ensuring that there are no interformational leaks.

Regulations applicable to CO₂ well monitoring

CO₂ injection wells, especially those classified as Class VI, must comply with strict safety standards to ensure their integrity and minimize environmental risks. In the United States, the Environmental Protection Agency (EPA) establishes periodic well integrity monitoring (WIM) protocols, which include pressure inspections, cementing reviews, leak tests, and detailed documentation of each operation. These measures seek to ensure that injection does not cause leaks into aquifers or other sensitive geological formations.

In Europe, the Geological Storage of CO₂ Directive (2009/31/EC) defines a similar regulatory framework, requiring operators to implement monitoring plans, periodic reports, and corrective measures in the event of any deviations. The regulations include inspection procedures before, during, and after the operation, ensuring the traceability of the injected CO₂ and the protection of the environment.

In addition to the EPA and European regulations, there are international standards issued by organizations such as ISO and ASTM, which specify measurement methods, risk assessment criteria, and protocols for ensuring well integrity. The application of these standards allows for the standardization of procedures and ensures consistency in global operations, facilitating the auditing and certification of safe practices.

Compliance with these regulations is crucial not only to avoid legal penalties, but also to protect the reputation of companies and the safety of the community and the surrounding ecosystem. For this reason, comprehensive monitoring programs include not only physical inspections, but also remote monitoring using sensors, digital records, and geological pressure and fracturing modeling, enabling proactive risk management.

Corrosion prevention in CO₂ injection wells

How to prevent CO₂ corrosion in tubing/casing?

Contact between CO₂ and water produces carbonic acid, a highly corrosive medium for carbon steels. This constitutes one of the main threats to the useful life of injection wells. Mitigation strategies include the following:

- Selection of resistant materials

- Use of corrosion-resistant alloys (CRA), such as duplex stainless steels or nickel alloys.

- Application of internal epoxy or ceramic coatings to reduce direct contact between CO₂ and steel.

- Corrosion inhibitors

- Chemicals are injected to form a protective layer on metal surfaces.

- They are used in both continuous injection and periodic treatments.

- Control of operating conditions

- Operate within pressure and temperature ranges that minimize water condensation.

- Design the well to reduce stagnation zones where the aqueous phase accumulates.

- Real-time corrosion monitoring

- Corrosion sensors and metal coupons installed in the injection line.

- Periodic inspection with corrosion logs.

As a practical example in pilot projects such as Sleipner (Norway), CRA was implemented in critical sections of the well, combined with geochemical monitoring in aquifers. This has allowed for more than 25 years of operation without significant corrosion failures.

Monitoring, reporting, and verification of CO₂ leaks

Monitoring is the tool that ensures transparency and traceability in geological carbon storage projects. Its application ensures that injections are safe, permanent, and verifiable by third parties. The most applicable monitoring techniques are presented below.

- Well monitoring

- Pressure, temperature, and flow sensors installed in real time.

- They allow the detection of anomalies that indicate leaks or changes in integrity.

- 4D seismic monitoring

- Uses repeated seismic tomography to observe CO₂ migration in the subsurface.

- It allows the identification of unexpected accumulations or possible leak routes.

- Surface geochemical sensors

- CO₂ detectors in soil, air, and surface aquifers.

- They complement subsurface data and serve as an environmental line of defense.

- Underground aquifer sampling

- Analysis of pH, alkalinity, and chemical composition.

- They allow for the detection of CO₂ dissolution in nearby waters.

- Predictive numerical modeling

- Multiphase flow simulations that anticipate possible CO₂ migration routes.

- Adjusted with real monitoring data for greater accuracy.

Technical and regulatory challenges in well integrity

Despite progress, significant challenges remain:

- Long-term durability: wells must remain stable for centuries, which exceeds the useful life of traditional oil wells.

- Geological heterogeneity: not all formations respond equally to CO₂ injection.

- Changing regulatory framework: different countries adopt specific regulations, creating a need for international standardization.

- Social acceptance: confidence in the integrity of wells is key to community acceptance of CCS projects.

Recommended best practices

- Redundant safety barrier design: cement, casing, and tubing as multiple lines of defense.

- Scheduled maintenance: apply MIT periodically throughout the project’s lifetime.

- Use of digital technologies: artificial intelligence for predictive analysis of corrosion and pressure data.

- Alignment with international standards: comply with ISO, API, and regional directives to obtain certifications.

As a complement, I invite you to watch the following video courtesy of: Climate Change.

CO₂ capture and storage.

Conclusion

The integrity of wells for geological CO₂ storage is essential for the safety and efficiency of carbon capture and storage projects. MITs ensure reliable initial conditions, corrosion prevention strategies extend operational life, and MRV systems enable early monitoring and detection of leaks. Guaranteeing these aspects reinforces confidence in the technology and consolidates carbon storage as an effective tool against climate change.

References

- Environmental Protection Agency. (2025). Class VI – Wells used for geologic sequestration of carbon dioxide. Retrieved from https://www.epa.gov/uic/class-vi-wells-used-geologic-sequestration-carbon-dioxide

- Comisión Europea. (2024). Guidance document 1: CO₂ storage life cycle and risk management framework. Retrieved from https://climate.ec.europa.eu/document/download/951d14ea-ce0f-4753-92dd-35ba88920888_en?filename=ccs-implementation_gd1_en_0.pdf

- International Organization for Standardization. (2017). ISO 27914:2017 – Carbon dioxide capture, transportation and geological storage — General requirements. Retrieved from https://www.iso.org/obp/ui/es/

FAQs

What MIT should be applied before injecting CO₂?

The most commonly used mechanical integrity test (MIT) is pressure testing on the casing and tubing, as this allows the tightness of the well to be confirmed before injection. It is complemented by sonic or cement logs to verify the adhesion of the cement to the formation and ensure that there are no leakage channels.

How to prevent CO₂ corrosion in tubing/casing?

Corrosion is controlled through the use of resistant steels, internal coatings, and chemical inhibitor programs. In addition, constant monitoring of the composition of the injected fluid is recommended to reduce the presence of free water, the main catalyst for corrosion.

Which MRV will you use to detect CO₂ leaks?

Monitoring, reporting, and verification (MRV) combines techniques such as pressure and temperature logging in the well, surface CO₂ sensors, and high-resolution seismic methods. These systems enable early detection of deviations and ensure that the gas remains confined in the formation.