Table of Contents

- What does the API RP 651 standard consist of?

- Above ground storage tanks

- Corrosion and prevention in storage tanks

- Cathodic protection for oil storage tanks

- Types of cathodic protection

- Internal cathodic protection on tank floors

- External cathodic protection on tank floors

- Consequences of tank floor leaks

- Conclusions

- References

Above ground oil storage tanks are necessary elements in the oil and gas industry. Recommended Practice API RP 651, developed by the American Petroleum Institute (API), establishes guidelines for the cathodic protection of these tanks, with a particular focus on preventing corrosion of tank floors. Applying this recommended practice ensures the structural integrity and operational safety of tanks, minimizing the risks associated with leaks and corrosion damage.

What does the API RP 651 standard consist of?

API RP 651 , or “Recommended Practice for Cathodic Protection of Aboveground Petroleum Storage Tanks” was originally published in 1997 and is a set of guidelines developed by industry experts for the application of cathodic protection systems on aboveground petroleum storage tanks on the floor. Its main objective is to prevent internal and external corrosion of tanks, thus extending their useful life and reducing the possibility of failure.

Above ground storage tanks

Above ground storage tanks are essential structures for storing large volumes of oil and its derivatives. These tanks vary in size and design, but share the characteristic of being perched on the ground. The API RP 651 standard focuses on providing specific guidelines to mitigate the corrosion risks of these tanks, especially on their floors, where corrosion can be most insidious and dangerous.

Corrosion and prevention in storage tanks

Corrosion in the bottoms of storage tanks can be caused by various factors: Internally, it is influenced by the components of the stored products, such as chemicals, humidity and sludge, among others. and on the outside, the area exposed above the ground, is the most susceptible to corrosion damage due to the entry of external contaminants and moisture, through the spaces that exist between the metal plates and the base of the tank, and in porous bases.

API Practice RP 651 addresses these cases by providing specific methods for evaluating potential corrosion, determining the appropriate number of cathode anodes, and establishing criteria for continuous monitoring, ensuring that facilities meet the most rigorous standards.

Cathodic protection for oil storage tanks

Cathodic protection is based on an electrochemical principle; it is used to control the corrosion of metals in submerged or buried structures. This principle involves the conversion of active areas into passive metal surfaces, that is, transforming them into the cathode of an electrochemical cell.

For above-ground storage tanks, this method is used to preserve the bottoms of the tanks. API RP 651 provides detailed guidelines on the installation, monitoring and maintenance of cathodic protection systems, covering the use of sacrificial anodes and impressed current.

Types of cathodic protection

There are two types of cathodic protection:

Cathodic protection by sacrificial anodes

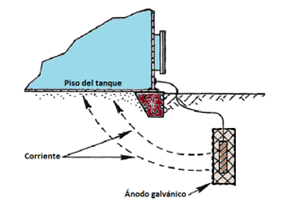

It is the simplest method. The metal to be protected (cathode) is connected to another more active metal, so that the latter acts as an anode. Zinc, aluminum and magnesium are metals commonly used as anodes to protect metal structures. Figure 1 presents an image of the arrangement of the galvanic protection method using sacrificial anodes.

As the drive voltage of sacrificial anodes is low compared to impressed current anodes, sacrificial anodes should be well distributed and located closer to the area being protected. Its use is feasible when specific protection is required and the budget investment is less than that required for printed current systems. The basic principle of anodes consists of metals more reactive than the tank steel, which are strategically installed in the tank.

These anodes act as a source of electrons, corroding and protecting the metal structure. As corrosion of the anode increases, it must be replaced to maintain system effectiveness. The API RP 651 standard specifies the proper quantity and location of these anodes to ensure optimal protection.

Cathodic protection by impressed current

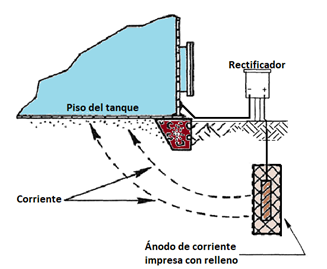

Impressed current cathodic protection (ICCP) uses electrical power provided by an external regulated direct current power supply, through a control panel. The control panel regulates the current necessary to polarize the surface to be protected. The protective current is distributed through anodes that are less active than the structure to be protected. One of the most common for application is titanium anodes coated with a metal oxide.

Figure 2 shows a graphic representation of cathodic protection by impressed current. This system uses a direct current source to negatively polarize the tank structure, thus preventing the formation of corrosion. Unlike sacrificial anodes, the impressed current is continuous and can be controlled more precisely. API RP 651 provides detailed guidelines on the design, installation, and monitoring of impressed current systems.

Internal cathodic protection on tank floors

The design of an internal cathodic protection system is complicated due to the different accumulated corrosive media such as water, the composition of sludge and other contaminants that could have a negative effect on the performance of the cathodic protection system. Due to the numerous variables associated with the design of internal cathodic protection for petroleum storage tanks, the use of this type of system is limited.

External cathodic protection on tank floors

For the implementation of cathodic protection on the outside of the tank floor, two forms can be used: Protection by sacrificial anode and by impressed current, the protection of the sacrificial anode due to the limited voltage, can be more economical in tanks of diameter small, but not suitable for large diameter tanks, due to the large current demand, in these cases the impressed current type of cathodic protection is generally used. API RP 651 describes guidelines for the application of cathodic protection in this area.

Consequences of tank floor leaks

Leaks into the bottoms of storage tanks can have serious safety and environmental consequences. In addition to the economic loss associated with the leakage of stored products, soil and water contamination is one of the most serious. Corrosion in storage tank floors can trigger massive leaks that could surpass retaining walls and reach the sea, lakes or rivers.

Even if these walls are not exceeded, the retained products could infiltrate the water table, contaminating both soil and water. Figure 3 shows an example of a leak in a hydrocarbon storage tank. API RP 651 is presented as a standard against these risks, providing the procedures that must be followed for the effective implementation of cathodic protection systems to prevent corrosion and, therefore, leaks and filtrations.

Conclusions

In summary, API RP 651 is a very valuable tool for preserving the integrity of aboveground petroleum storage tanks. By focusing on cathodic protection, especially on tank bottoms, this recommended practice mitigates risks associated with corrosion, prevents leaks, and ensures operational safety.

API certification adds an additional level of trust, ensuring that facilities meet internationally recognized quality standards. In a world where safety and sustainability are priorities, the implementation of API RP 651 emerges as a crucial step in ensuring the long-term integrity of aboveground oil storage tanks.

References

Own source