Table of Contents

- What is the NACE TM0190 standard?

- Importance of Al anode testing in marine environments

- NACE TM0190 in quality assurance programs (QA)

- Method flexibility and test customization

- Relationship between laboratory testing and in service performance

- NACE TM0190 and the reliability of marine infrastructure

- Conclusions

- References

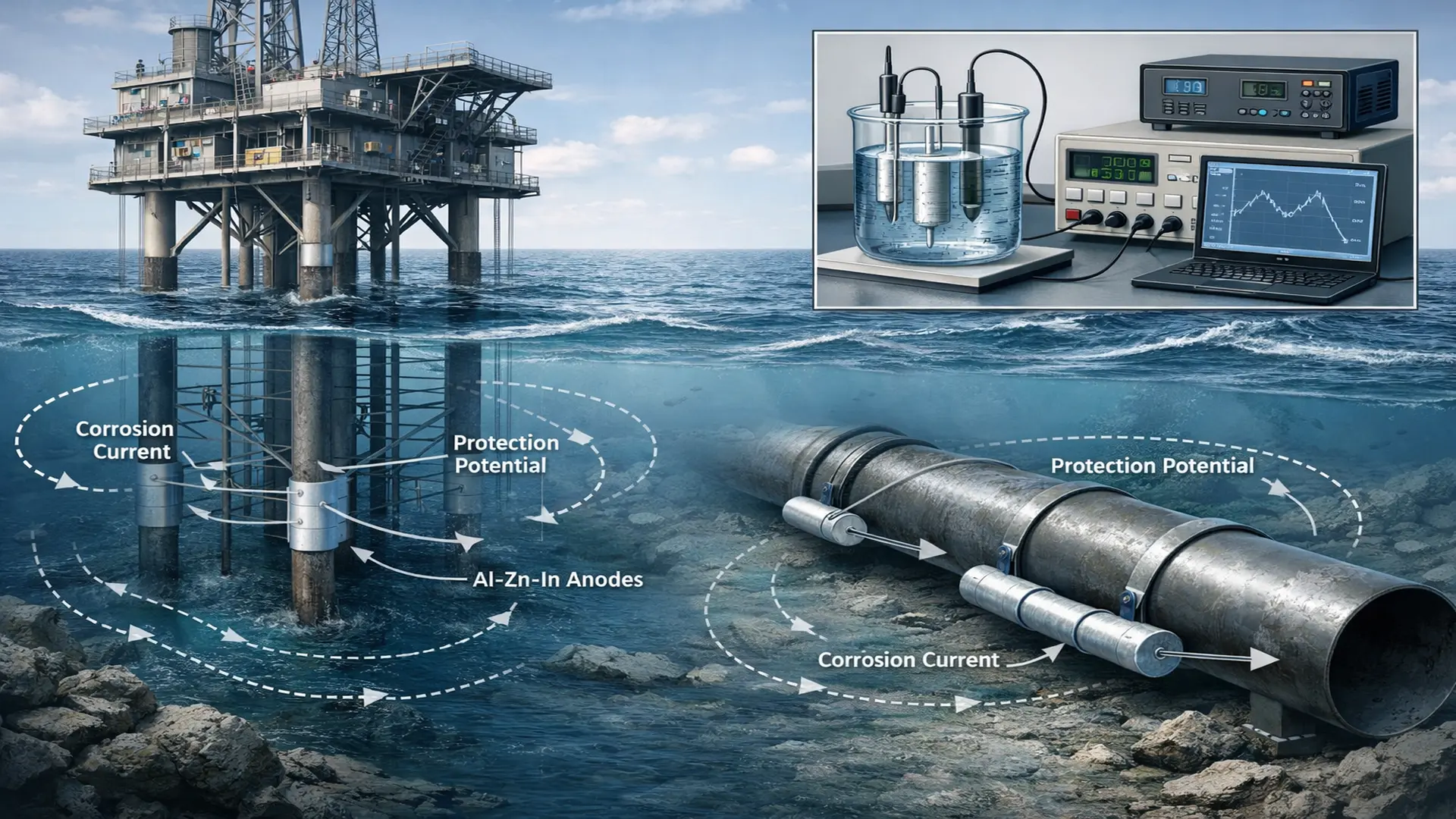

Corrosion represents one of the main factors of deterioration in metallic structures exposed to marine and offshore environments. To mitigate this phenomenon, cathodic protection using sacrificial anodes has become a widely used solution in the energy, naval, and petrochemical industries. Within this context, the NACE TM0190 standard establishes a standardized method for testing aluminum anodes, allowing their electrochemical performance to be verified prior to application in service.

The correct application of this standard is essential to ensure the reliability of marine cathodic protection systems, since anode quality directly influences the structural integrity and service life of the protected assets.

What is the NACE TM0190 standard?

NACE TM0190 is a test method designed to evaluate, under controlled laboratory conditions, the electrochemical characteristics of aluminum alloy anodes used in cathodic protection systems. This procedure is part of cathodic protection quality control programs and allows the determination of critical parameters such as anode electrochemical potential and current capacity.

These indicators are essential to validate that the material meets the technical requirements demanded by international standards, contractual specifications, and engineering design criteria.

Although the test is conducted in the laboratory, the standard emphasizes the need to correlate the results with the actual field behavior of the anode, where variables such as temperature, salinity, and hydrodynamic conditions may affect its performance.

Importance of Al anode testing in marine environments

Anodes manufactured from aluminum alloys, especially Al-Zn-In compositions, are widely used due to their high electrochemical efficiency, high current capacity, and lower structural weight compared to zinc or magnesium anodes.

However, the performance of these materials depends on multiple factors, including:

- Chemical composition of the material

- Alloy microstructure

- Metallurgical uniformity

- Casting and manufacturing processes

- Conditions of exposure to the electrolyte

Electrochemical evaluation of anodes using NACE TM0190 makes it possible to detect variations in these parameters and avoid the installation of materials that could exhibit premature failure or insufficient protection.

Parameters evaluated according to NACE TM0190

The test method mainly focuses on determining two fundamental properties:

Anode electrochemical potential

Electrochemical potential establishes the anode’s ability to polarize the protected metallic structure. This parameter is decisive in ensuring that the system maintains the required level of protection against corrosion.

Anode current capacity

Current capacity represents the amount of electrical charge that the anode can deliver over its service life. This value is essential for the design and sizing of cathodic protection systems, as it allows estimation of the anode’s operational lifetime.

NACE TM0190 in quality assurance programs (QA)

The standard is widely used by manufacturers, designers, and operators of cathodic protection systems as a tool for verifying the quality of sacrificial anodes.

For manufacturers, the test validates production process consistency and demonstrates compliance with technical specifications. For designers, it provides key information for calculating the required number and size of anodes. For end users, it represents technical support that reduces operational risks and maintenance costs.

In offshore projects, results obtained using NACE TM0190 are often part of quality plans and technical documentation required by international standards and certification bodies.

Method flexibility and test customization

Although the standard provides clear guidelines, it allows a certain degree of flexibility in test execution. Some laboratories adapt the procedure to facilitate the evaluation of large numbers of samples. Common modifications include:

- Surface preparation by chemical etching or machining

- Frequency of test electrolyte renewal

- Configuration of electrical circuits in parallel or series

- Simultaneous evaluation of different aluminum alloys

- Variations in the frequency of potential measurements

However, these adaptations must be carefully evaluated, as they may affect test sensitivity and reproducibility, leading to deviations in the interpretation of anode electrochemical performance.

Relationship between laboratory testing and in service performance

One of the most relevant aspects of NACE TM0190 is its focus on correlating laboratory testing with actual field performance. Anode behavior may vary when exposed to dynamic environmental conditions, such as changes in salinity or temperature.

For this reason, test results should be complemented with operational evaluations and in-service monitoring, allowing optimization of cathodic protection system design and improvement of predictive maintenance programs.

NACE TM0190 and the reliability of marine infrastructure

Application of this standard helps establish uniform criteria for the selection and evaluation of aluminum anodes, facilitating technical communication among manufacturers, contractors, and operators.

Its implementation allows:

- Reduction of accelerated corrosion risks

- Optimization of anticorrosion system performance

- Reduction of repair and maintenance costs

- Ensuring operational safety

- Extension of the service life of metallic structures

In an industrial environment where structural integrity is a priority, compliance with technical standards such as NACE TM0190 becomes a strategic tool to ensure operational sustainability.

Conclusions

The NACE TM0190 standard represents a fundamental pillar in the evaluation of the quality of aluminum anodes used in marine cathodic protection. Its application makes it possible to validate the electrochemical performance of materials, improve quality control processes, and ensure the reliability of infrastructure exposed to highly corrosive environments.

In an industry where corrosion can generate significant economic, environmental, and operational impacts, rigorous implementation of standardized test methods remains an essential practice for the comprehensive management of asset integrity.

References

- AMPP International. (2019). TM0190: Laboratory testing of aluminum alloy anodes for cathodic protection. AMPP International.

- DNV. (2017). Cathodic protection of offshore structures (DNV-RP-B401). Det Norske Veritas