Table of Contents

- Basic principle and fundamentals of Cathodic Protection (CP)

- Wear and corrosion in marine infrastructures

- Cathodic protection methods for reinforced concrete marine structures

- Implementation of cathodic protection in marine concrete structures

- Cathodic Protection Monitoring and Maintenance

- Challenges of cathodic protection systems in marine concrete infrastructures

- Conclusions

- References

The integrity of marine concrete infrastructure, essential to the global economy and coastal safety, faces a constant threat due to corrosion of reinforcing steel. This phenomenon not only compromises the durability and functionality of the structures, but also implies significant economic costs for maintenance and repairs.

In this context, cathodic protection is one of the most widely used methods to preserve infrastructures. Corrosion deteriorates the steel embedded in concrete and compromises structural integrity, hence the importance of implementing effective cathodic protection systems.

This article will not only illustrate the fundamentals and implementation of cathodic protection, but also emphasize its relevance in extending the service life of offshore infrastructures, thus ensuring their long-term operability and safety.

Basic principle and fundamentals of Cathodic Protection (CP)

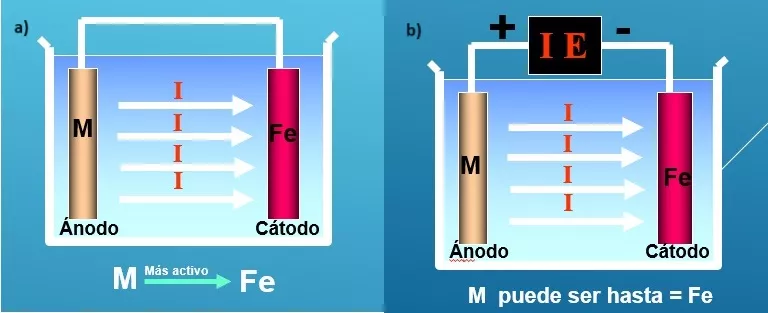

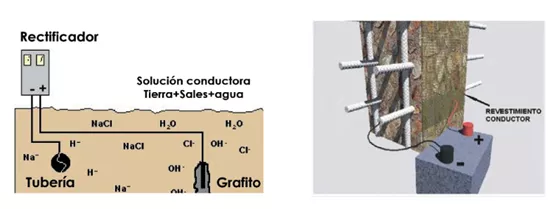

Cathodic protection is based on an electrochemical principle and consists of polarizing the metal towards its corresponding immunity zone in order to eliminate the anodic sites on the surface, so that the entire surface acts as a cathode. It is, in short, passing electrons to shift the following reaction to the left: (M → M+2 + 𝟐𝒆-). Protection can be provided either by sacrificial anodes or impressed current systems. In the first case, metals with open circuit potential lower than that of the structure to be protected (e.g. Al, Mg, Zn) are used. In the second case, in addition to the anodes, an impressed current rectifier is used (Figure 1).

Cathodic Protection can be used in different practical applications such as: Ships, oil platforms, buried and submerged pipelines, reinforced concrete structures, heaters. It is not effective in preventing corrosion caused by exposure to the atmosphere. In the case of reinforced concrete structures, this method is used to control metal corrosion in a saline conductive medium, such as reinforcing steel in concrete infrastructures exposed to marine environments.

For cathodic protection to be effective, several factors must be considered, such as the type of structure, the corrosive environment, and the resistivity of the medium. The anode and cathode (the metal to be protected) must be in electrical contact and immersed in an electrolyte (seawater, in the case of marine structures) to complete the electrochemical circuit. The correct selection and design of the Cathodic Protection system is significant for high system efficiency. By adjusting the electrochemical potential of the steel to a level where corrosion becomes negligible, long-term protection of the metal can be ensured, thus preserving the integrity and functionality of marine concrete structures.

Wear and corrosion in marine infrastructures

Marine infrastructures, such as ports, harbors and coastal protection barriers, are exposed to extremely hostile environmental conditions that significantly accelerate the corrosion process in reinforcing steel. Wear and corrosion in these structures are driven by a combination of factors, including the constant presence of saltwater, biofouling and the variability of environmental conditions such as temperature and humidity.

Salt water is particularly corrosive due to its high electrical conductivity and chloride content, which penetrates through the concrete and reaches the reinforcing steel (Figure 2). Chloride ions break down the passive layer of the steel, a thin film of oxides that protects the metal from corrosion, making the steel more susceptible to the corrosive process. This phenomenon is exacerbated in tidal zones, where the alternation of humidity and air increases the availability of oxygen, further accelerating corrosion.

Biofouling, the growth of marine organisms such as algae, mollusks and barnacles on the surfaces of structures, not only adds weight and structural strength, but can also create acidic microenvironments that corrode metal. In addition, biological activity can lead to differential oxygen concentration, exacerbating localized corrosion.

Other environmental factors, such as temperature changes and UV exposure, can also influence the corrosion rate. Thermal variation can cause expansion and contraction in concrete, generating microcracks through which salt water and chloride ions can penetrate more easily. UV radiation, on the other hand, degrades the organic components of concrete, decreasing its strength and increasing its porosity, which further facilitates the intrusion of corrosive agents.

These specific challenges demand design strategies, materials and protection methods to ensure the durability and structural integrity of marine infrastructures, where cathodic protection is fundamental in preventing corrosion of reinforcing steel, protecting the infrastructure from irreversible damage and prolonging its useful life.

Cathodic protection methods for reinforced concrete marine structures

In marine infrastructure protection, the two most commonly employed approaches are the use of sacrificial anodes and impressed current systems. Both methods are fundamentally aimed at reducing the corrosion rate of reinforcing steel in concrete by converting the entire metal surface into the cathode of an electrochemical circuit. However, the choice between one method and the other depends on several factors related to the specific characteristics of the structure and the environmental conditions to which it is exposed.

Sacrificial anodes

This method involves the use of metals with higher electrochemical activity (higher electrode potential) than steel, such as zinc, magnesium or aluminum. These anodes are “sacrificed” by preferentially corroding, thus protecting the reinforcing steel (Figure 3). Sacrificial anodes are particularly suitable for small to medium sized structures due to their simplicity and the fact that they do not require an external power source. Their effectiveness is limited by the lifetime of the sacrificial anode, after which they must be replaced. The choice of anode material depends on the conductivity of the water and the type of protected structure.

Printed current systems

These systems use an external direct current source to apply a flow of electrons to the reinforcing steel from an external anode, usually made of durable materials such as silicon or titanium coated with mixed metal oxide. Impressed current systems are ideal for large and complex structures, where the uniformity of cathodic protection can be precisely controlled and adjusted (Figure 4). Although they are more costly and technically challenging to install and maintain than sacrificial anodes, they offer a long-term solution without the need for frequent replacement.

The selection of the appropriate method of cathodic protection depends on a detailed evaluation of the structure, including its size, complexity, accessibility for maintenance and environmental conditions. While sacrificial anodes can be cheaper and easier to install for smaller or less critical applications, impressed current systems offer a more adaptable and durable solution for large or strategically important marine infrastructure, ensuring effective corrosion protection over time.

Implementation of cathodic protection in marine concrete structures

Effective implementation of Cathodic Protection systems on marine concrete structures begins with a detailed evaluation of the existing structure to determine the most appropriate method of protection, either sacrificial anodes or impressed current systems. Material selection is critical; for example, zinc and aluminum are preferred for sacrificial anodes in marine environments due to their effectiveness in salt water.

The system design must ensure uniform current distribution to protect all areas vulnerable to corrosive wear. In addition, it is critical to consider the ease of integration with the existing structure, which may require specialized installation and attachment techniques of the Cathodic Protection system components so as not to compromise the structural integrity of the concrete. This process should also contemplate future expansions or modifications to the structure, ensuring that the installed system can be adapted or expanded as needed.

Cathodic Protection Monitoring and Maintenance

Regular monitoring and proactive maintenance are necessary to ensure the continued effectiveness of cathodic protection systems in marine concrete infrastructure. Monitoring involves the use of specialized techniques and tools, such as potentiometers and data loggers, to assess system status and performance. These devices can help identify areas where the protective current may be insufficient or excessive, which could indicate the need for system adjustments.

Periodic maintenance may include cleaning system components, replacing worn sacrificial anodes and checking electrical connections to ensure optimum corrosion protection. The implementation of a detailed monitoring and maintenance plan (Figure 5) helps prevent system failures and significantly extends the life of the protected structure, thus ensuring the integrity and functionality of critical marine infrastructure.

Challenges of cathodic protection systems in marine concrete infrastructures

These systems will present several challenges in the future, driven by climate change, technological evolution and increasing demands for sustainability and efficiency. The following are some of the main challenges and how they could impact the implementation and effectiveness of these systems:

Adaptation to climate change

Climate change poses significant challenges to marine concrete structures, including sea level rise, increased frequency of extreme weather events, and variability of saline conditions. These factors can accelerate corrosive processes and require more resilient and adaptive cathodic protection systems capable of adjusting to changing and more aggressive environmental conditions.

Technological advances and innovative materials

Research and development of new materials and technologies offer opportunities to improve the effectiveness of cathodic protection systems. More durable and efficient anode materials, as well as innovations in remote and real-time monitoring technologies, may enable more efficient and lower maintenance systems. However, integrating these innovations into standard practices will require overcoming technical, cost and regulatory barriers.

Sustainability and environmental considerations

The growing concern for sustainability and the environmental impact of industrial operations demands that cathodic protection systems be not only effective but also environmentally responsible. This includes minimizing the environmental impact of sacrificial anodes and optimizing the energy consumption of impressed current systems. Challenges include the development of greener anodes and energy-efficient systems that reduce the overall carbon footprint.

Regulatory and regulatory compliance

Environmental regulations and standards are evolving rapidly, and are likely to become more stringent in the future, affecting the implementation of cathodic protection systems. Professionals will need to keep up with these regulations and ensure that cathodic protection systems comply with the new standards, which may require adjustments in design, installation and maintenance practices.

Education and training

As cathodic protection systems become more complex and technologically advanced, the need for specialized training and continuing education for the engineers and technicians responsible for their implementation and maintenance becomes critical. Ensuring that staff are well informed about the latest trends, techniques and regulations will be essential to address future challenges.

Cathodic protection systems in concrete structures will face a number of challenges in the future, requiring a combination of technological innovation, sustainable approaches, regulatory compliance and continuing education to ensure their long-term effectiveness and sustainability.

Conclusions

Cathodic Protection is consolidating as an indispensable method to counteract corrosion of reinforcing steel in marine concrete infrastructures, a crucial element for the global economy and coastal safety. The effectiveness of protection, through sacrificial anodes or impressed current systems, depends on careful selection of materials, proper design and continuous monitoring and maintenance.

Overcoming these challenges in Cathodic Protection requires a combination of technological innovation, sustainable approaches, and a commitment to education and continuous training of industry professionals. Thus, the systems represent not only a technical solution for the preservation of critical infrastructures, but also a field of continuous development that demands adaptation and evolution in the face of emerging challenges, ensuring their relevance and effectiveness in the future.

References

Own source