As part of the PANNDT 2025 conference held in Canada, the Inspenet team was able to interview Stéphane Couture, Global Product Applications Leader at Evident Canada Inc, one of the most influential technical figures in the industry. During the interview, Stéphane shared how the company is transforming the NDT technology landscape through technical advancements, regional standards and a sustainable approach adapted to today's industry challenges.

Evident was born as an evolution of the scientific division of Olympus, with even older roots in RD Tech, which has allowed the company to preserve a solid technical base, thanks to the permanence of engineers and technicians with more than two decades of experience. According to Couture, the accumulated knowledge of the team has been key to consolidating the most advanced inspection solutions on the market, such as the total focus methodology (TFM) and the phase coherence imaging (PCI).

This heritage has not been an anchor, but a springboard and is reflected in a technical team that combines experience and new talent, capable of developing equipment such as the OmniScan X4, a multi-technology platform capable of integrating ultrasound, phased array and TFM in a single device.

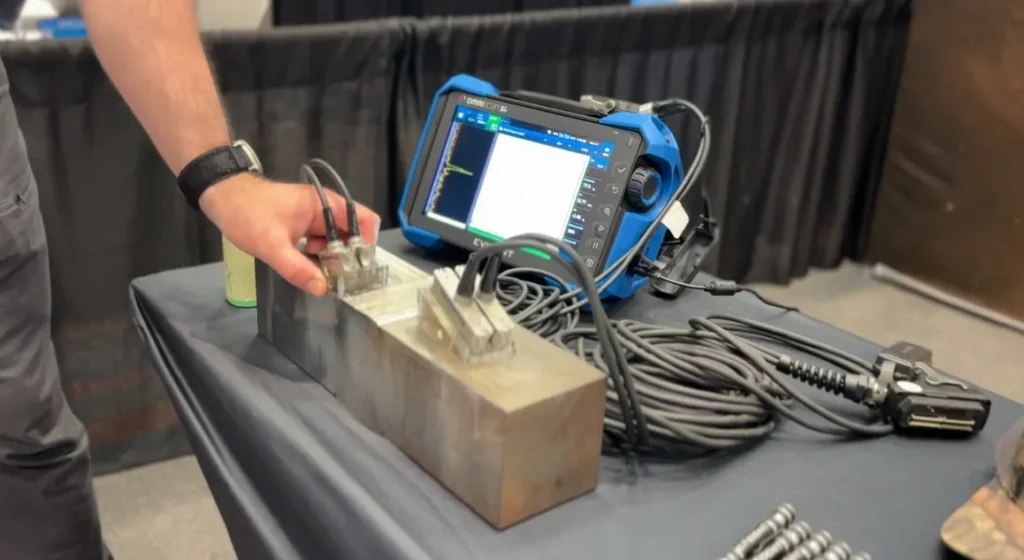

During the show, Evident's team presented a live demonstration using a 100 mm thick test block composed of stainless steel, carbon steel and Inconel weld and by using dual linear array probes, demonstrated the OmniScan X4's ability to visualize internal defects, such as side holes and notches, in typically complex materials.

The transition between TFM and PCI in real time showed that each technique has particular advantages depending on the material and type of defect. While TFM provides a more stable and accurate image, PCI offers better visualization of certain indications with higher contrast, albeit with somewhat more noise.

The use case presented was especially relevant for industries such as nuclear or power generation, where the detection of internal defects in austenitic materials is crucial. In addition, the OmniScan X4 interface allows real-time switching and overlaying of views, facilitating the inspector's interpretation and improving decision making in the field.

Recently, the Canadian non-destructive testing community took a significant step forward by establishing the first Canadian standard for phased array, a certification that puts Canada on an equal footing with other regions such as the United Kingdom (CSWIP) or Europe (PCN).

This new regulatory framework was developed by the Canadian NDT community and approved by NRCan (Natural Resources Canada). Its objective is to offer a system of levels (1, 2 and 3) for phased array similar to that which already exists for other ultrasound methodologies, improving the professionalization of the sector, reducing dependence on foreign certifications and standardizing technical competencies within the country.

Evident, being part of the launch event and having experience in training and technical validation, is delighted by implementation of the standard.

We as a community, just released the phase array Canadian standard for phase array, which is a first. […] So as the Canadian industry moves forward, we now have a Canadian based standard to really play with the other continents, the other countries of the world, such as the C-SWIP in the UK, the, what are the PCN levels. Now we have the NRCan levels as well.

Stéphane Couture.

For manufacturers and users of NDT technology, this new standard represents an opportunity to harmonize training with the demands of the global market, without losing the identity and particular needs of the Canadian market.

With a presence in 57 countries and 40 local service centers, the company takes a decentralized approach to training. Its strategy combines local specialists with training designed to suit the specific needs of each customer.

Since the pandemic, the proportion of virtual training has grown dramatically and online sessions, powered by cameras and screen projections, have enabled remote training without sacrificing technical quality. However, Couture acknowledges that face-to-face contact remains key for critical applications and tactile knowledge transfer.

Evident is taking firm steps towards digital integration, thanks to its equipment now operating under open platforms, allowing inspection data to be integrated directly into digital twins or CAD platforms, reducing processing times and improving data-driven decision making.

Additionally, the company is evaluating complementary technologies such as drones and crawlers to inspect hard-to-reach areas, which represents added value in industries where direct access poses health or safety risks.

During the event, Stéphane Couture shared that Evident will also be present at the next edition of the ASNT congress in October. The company is positioned as a key player not only for its technology, but also for its ability to establish close technical relationships with its customers locally and internationally.

For more content on PANNDT 2025, visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.