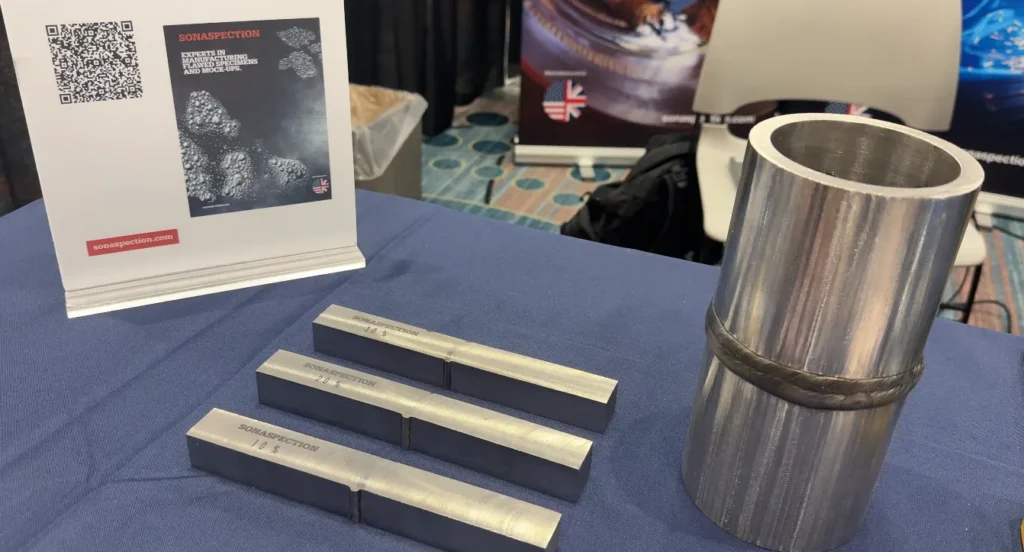

At PANNDT, one of the most relevant fairs in the non-destructive testing (NDT) sector, Jeremy Ring, President of Sonaspection, shared how his company has consolidated its global leadership in the manufacture of flawed specimens. The interview revolved around technical innovation, customer adaptability, and compliance with the most demanding international standards.

Founded in 1980, the company is recognized as the longest-standing manufacturer of simulated flaw samples for NDT. Headquartered in Charlotte, North Carolina, and supported by its UK subsidiary, it maintains effective international coverage, dividing logistical operations to serve both North America and the rest of the world.

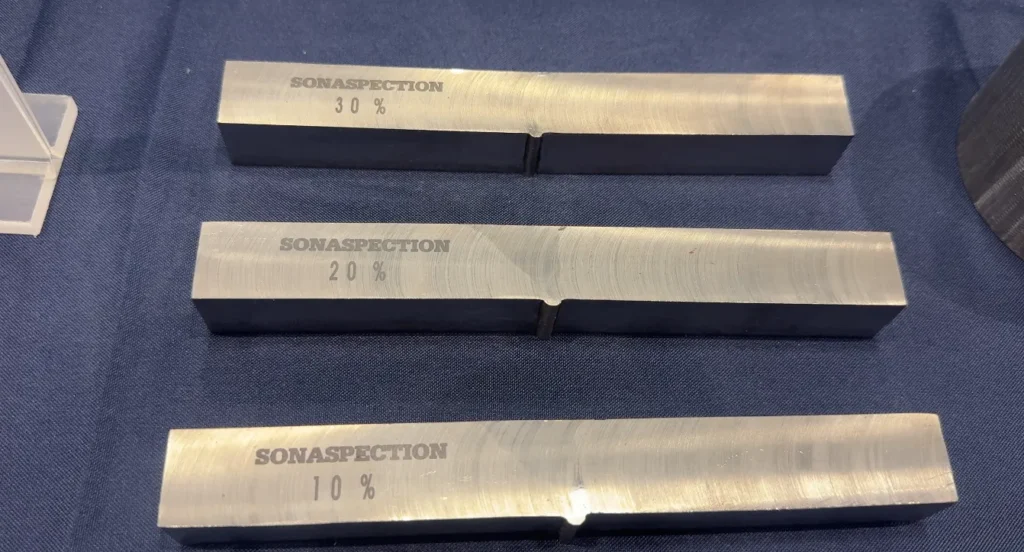

One of the most impressive aspects of Sonaspection's operation is its ability to manufacture reproducible and reliable flawed specimens. These are training pieces manufactured with intentional and controlled defects, such as cracks, porosities, inclusions, or corrosion, in order to simulate real conditions for inspectors in training to learn to detect them using ultrasound, radiography, or other techniques.

Their highly qualified welders manage to control internal flaws to a margin of 15 thousandths of an inch, ensuring that each piece fulfills didactic functions in training and certification tests. This means that the inspector receives a component that faithfully simulates real conditions, allowing them to practice and identify flaws with a high degree of realism.

The manufacture of defective specimens, apart from functioning as endorsements for inspection equipment or industrial processes in critical sectors, is fundamental in technical certification under standards such as ISO 9712 or ASNT. Jeremy Ring comments that their program is based on the ISO 9001 standard, complemented with guidelines from the NQA-1 system, widely used in the nuclear field, which allows them to comply with the requirements of key standards in the certification of technical personnel.

Additionally, Sonaspection frequently collaborates with institutions such as EPRI (Electric Power Research Institute), which reinforces their experience in regulated and high-security environments.

Beyond their standard line, Sonaspection offers customized pieces to replicate specific defects. These requests often come from sectors such as nuclear energy or aviation, where it's necessary to simulate defects of complex morphology or very particular service conditions.

To achieve this, the company employs 3D laser scanning technology, which allows them to accurately capture the geometry of real flaws. Then, this data is processed and transferred to CNC (Computer Numerical Control) systems, which allow the defective sample to be manufactured with maximum fidelity, so that trainers and auditors can evaluate detection capability in situations that faithfully mimic the operating environment.

A fundamental part of Sonaspection's work model is the constant feedback with training institutions, regulatory bodies, and industrial clients, which allows them to anticipate trends and adapt the design of their products. This feedback materializes in adjustments to flaw designs, new geometric configurations, and changes in the materials used, all with the aim of ensuring that flawed specimens continue to be a high-value didactic tool.

Participating in events like PANNDT 2025 not only allows for showcasing products, but it also represents a way to maintain a close relationship with key players in the sector. Jeremy emphasized the importance of strengthening ties, listening to concerns, and identifying emerging needs in these spaces.

With more than four decades of experience, Sonaspection has established itself as a key provider of flawed specimens for training and certification in non-destructive testing. Technical precision, customization, regulatory compliance, and closeness to the market position the company as an indispensable player in the training of highly qualified inspectors.

For more content about PANNDT 2025, visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.