At AMPP 2024, Cortest Inc., a leader in customized laboratory testing equipment, introduced the Hydrogen Test Enclosure, its latest innovation. This new solution was presented by Leonardo Uller, Global New Business Advisor, and Derrek Leiter, Instrumentation Specialist.

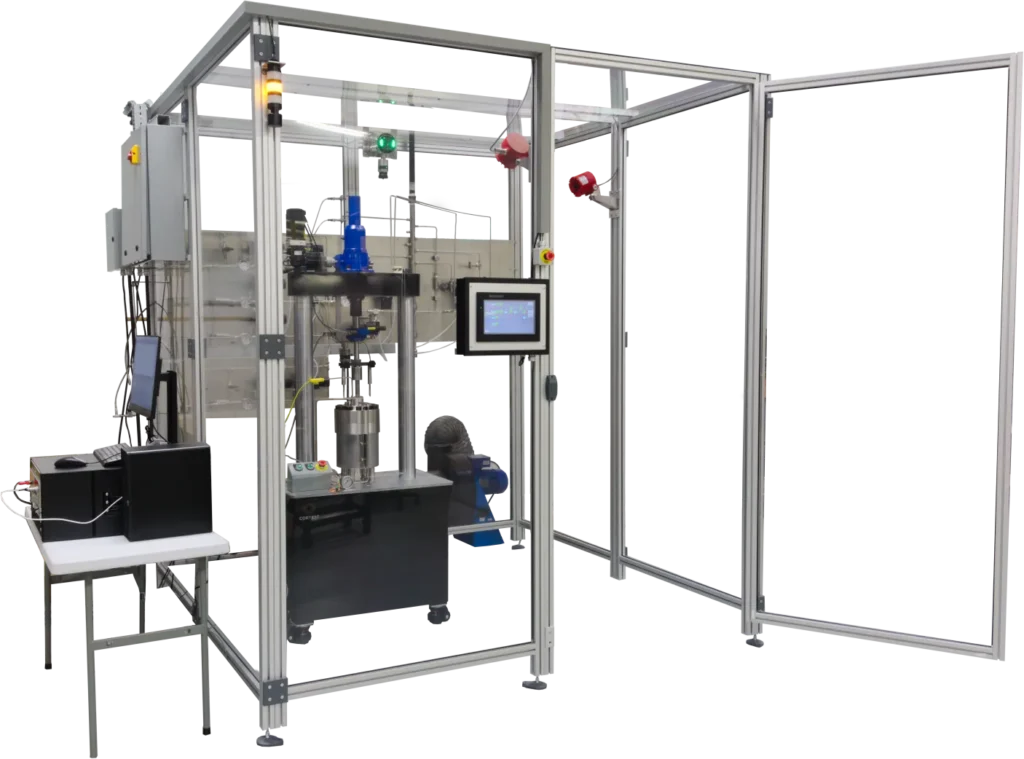

Hydrogen is poised to become a key player in the future of clean energy, however, its high volatility and potential hazards demand rigorous safety protocols in material testing. Cortest’s Hydrogen Test Enclosure provides a controlled, fully automated, and secure environment for laboratories that lack hydrogen-specific certifications.

Hydrogen will be probably the new future, new fuel in the future. And we are testing because we need to test with safety. Hydrogen is dangerous. And then what we did is exactly that, to have an enclosure that we can work inside with all safety.

Leonardo Uller.

The Hydrogen Test Enclosure is designed to enable high-temperature, high-pressure material testing in a hydrogen atmosphere. It features:

What it does is if you have a lab that's not really certified for hydrogen, this is kind of an all-inclusive enclosure you can put in your lab so that you can work with hydrogen in safety.

Derrek Leiter.

With the global push toward hydrogen as a clean energy source, ensuring material integrity and safety is crucial. Cortest’s Hydrogen Test Enclosure supports oil and gas, nuclear, and renewable energy sectors in testing materials designed for hydrogen-based applications.

Cortest has been a pioneer in high-temperature, high-pressure corrosion testing equipment for over 47 years. By introducing hydrogen testing solutions, the company reaffirms its commitment to innovation and safety in the evolving energy landscape.

For more AMPP 2024 content, visit our YouTube channel and LinkedIn profile.

Source: Inspenet.