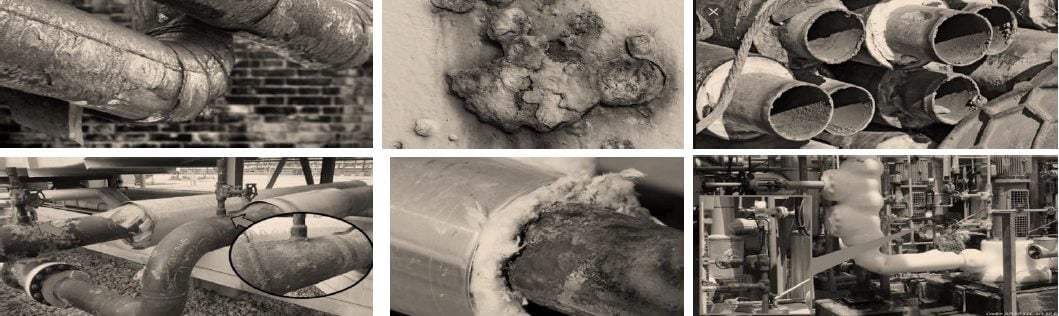

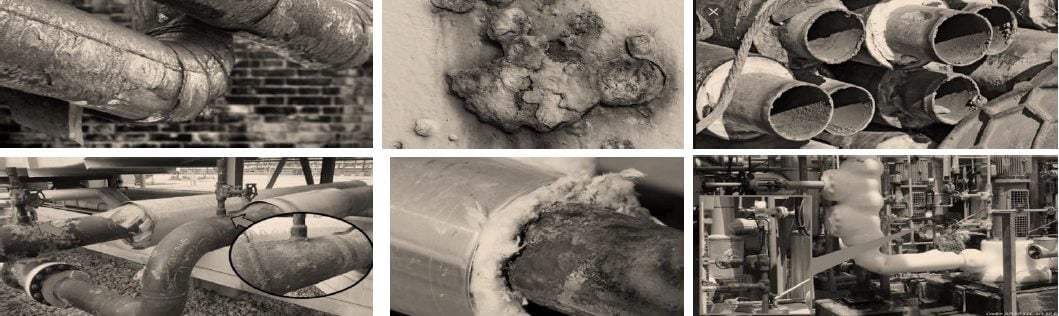

Detecting Corrosion Under Insulation with Advanced NDT Methods

The selection of the NDT method depends on the type of insulation, wall thickness and accessibility of the pipe.

The selection of the NDT method depends on the type of insulation, wall thickness and accessibility of the pipe.

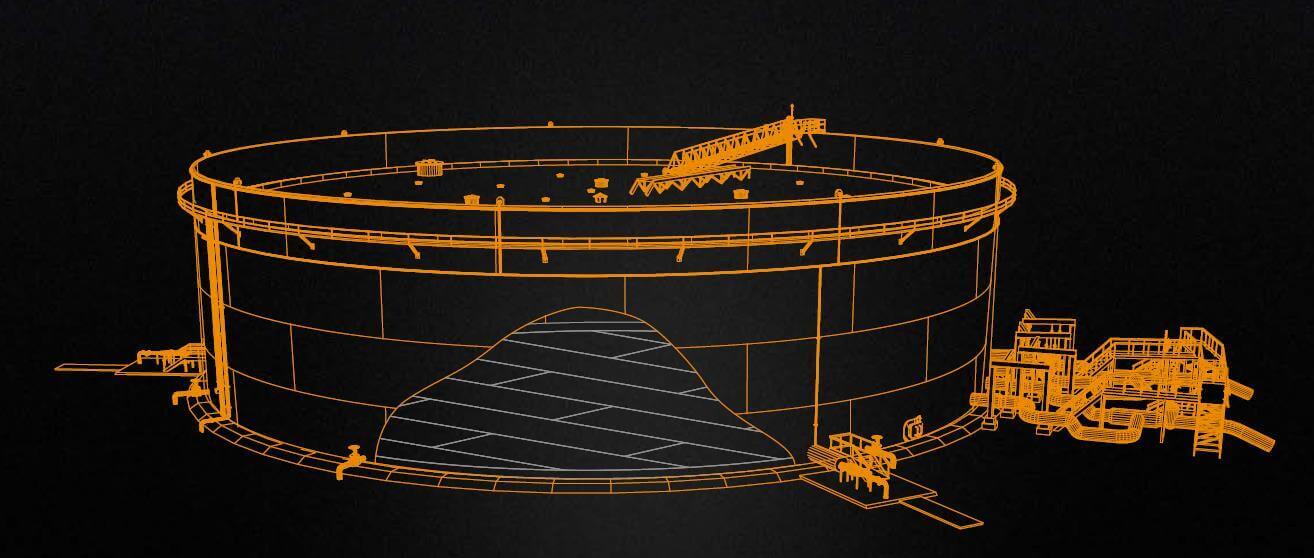

NDTs allow for the evaluation and assurance of optimal tank conditions during deployment, repair, and industrial maintenance.

NDTs ensure that a storage tank meets safe and operational conditions before being put into operation.

Introduction Industrial maintenance and reliability strategies Reliability Centered Maintenance (RCM) is a very powerful methodology that, when applied correctly, can lead to significant improvements in equipment reliability and plant performance while at the same time ensuring that money spent on predictive and preventive maintenance programs is optimised.All those involved in the operation of an industrial […]

Brief introduction of technical aspects and basic notions of the Ultrasonic Guided Wave (UGW) technique.

Summary An exhibition is presented on the use of visual inspection tools in boiler pipes, external and internal, in order to identify and diagnose the integrity…

Climate change is a complex phenomenon that represents one of the great challenges of the 21st century due to its characteristics, causes and global consequences, which…

Organizational and cultural factors that make it difficult to integrate maintenance as a key part of the production process.

Inspection of storage tanks according to American Petroleum Institute (API) standards are important to prevent not only catastrophic failures, but also to avoid problems related to the mechanical integrity of the assets affected mainly by corrosion in floors, walls and ceilings.