A technical look at algorithmic tools in the optimization of the monitoring of solar installations exposed to aggressive environments.

Photovoltaic energy has experienced exponential growth in the last decade consolidating itself as one of the most widespread renewable energy sources in the world. The global expansion of solar PV systems has been a strong response to the energy and climate challenges.

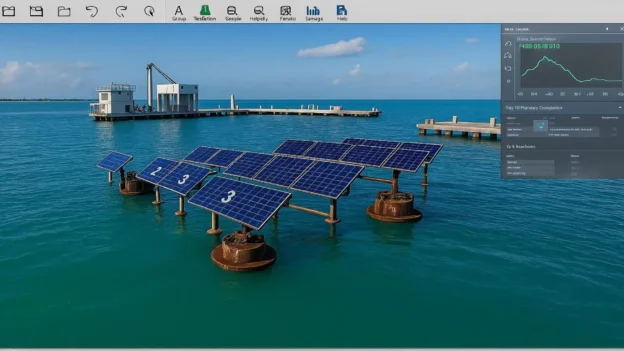

However, installations in hostile environments, such as maritime areas with high salinity, deserts with extreme thermal changes or urban regions with atmospheric pollutants, have shown corrosion problems that directly affect operational reliability and require integrated technological monitoring solutions for proper control.

Although solar modules are designed and built with materials resistant to aggressive weather conditions, the metallic structures (frames, anchors, hardware) and electrical components (connectors, tracks, junction boxes) are exposed to corrosive processes that deteriorate the physical structure and reduce the useful life of these assets. Hence, the importance of detecting corrosion of solar structures in these environments; however, traditional methods for this purpose do not offer the speed, objectivity or coverage required for large-scale installations.

Faced with this limitation, the renewable energy sector, in particular photovoltaics, is incorporating computational detection solutions, which integrate mathematical algorithms, computer vision and even artificial intelligence models, to optimize the monitoring of corrosion deterioration.

Corrosion in photovoltaic systems

Corrosion in photovoltaic systems is a significant problem in the photovoltaic industry. Prolonged exposure to aggressive atmospheric environments, such as humidity, atmospheric pollutants (SO2, NOx, chlorides), ultraviolet radiation and thermal variations, induce corrosive mechanisms that compromise both the operational reliability and lifetime of solar panels; affecting the integrity of the structural frames by crevice or pitting corrosion phenomena, while in the electrical elements (connectors, junction boxes, conductive tracks), the formation of oxides and sulfides can generate increases in contact resistance and arcing failures.

Computational tools for corrosion detection

Computational detection comprises a spectrum of techniques, from traditional image processing to machine learning algorithms; both strands can act in a complementary manner, depending on the desired level of complexity and accuracy. These are then classical approaches and AI approaches.

Classical approaches

- Image processing (OpenCV, MATLAB): Techniques such as edge detection (Sobel, Canny), thresholding, texture analysis or mathematical morphology allow identifying visual patterns of surface corrosion, discolorations or cracks.

- Spectral analysis: Algorithms detect alterations in spectral, hyperspectral or infrared images; associated with corrosion products or other degradation indicators.

- Temporal comparison: Automatic analysis of images acquired in time series to detect and quantify the evolution of structural or surface deterioration.

These methods do not require training with large datasets but may have limitations under variable lighting conditions or complex damage patterns.

Artificial intelligence approaches

Today, with the development of computational techniques, artificial intelligence (AI) is playing an increasingly important role in the field of scientific research. The incorporation of AI in computational detection has overcome some of the previous limitations.

The most commonly used models are:

- Convolutional neural networks (CNN): trained on thousands of images of panels with and without corrosion, these networks can detect defects even in challenging lighting conditions.

- Classification models (YOLO, Faster R-CNN): They can identify multiple types of damage simultaneously in the same image (pitting corrosion, surface rust, moisture stains).

- Semantic segmentation (U-Net): Delimit the exact areas affected, estimating their surface area and degree of deterioration.

- Temporal analysis with LSTM networks: Used in installations with continuous monitoring, these networks can predict the evolution of corrosion over time.

Although the training of these models requires large databases with identified images, once implemented, they far exceed the capabilities of conventional methods, especially under varying conditions. Compatible with SCADA platforms or predictive maintenance software.

Real applications and tangible benefits

Currently, industrial photovoltaic plants have already incorporated computational detection systems with verifiable results, achieving a reduction of more than 70% in inspection times, reduced direct intervention of technical personnel and lower corrective maintenance costs. In harsh environments, such as deserts in northern Chile1 or coastal areas in Saudi Arabia2, these technologies have established themselves as key tools to protect critical solar assets.

Current and future challenges

Despite the benefits, computational corrosion detection in PV systems still faces challenges. The availability of specialized databases with images representing different types of panels and environmental conditions is required. Barriers also remain, such as adapting algorithms to various solar module configurations, integration with existing infrastructures and interoperability with SCADA platforms or maintenance software.

The development points towards hybrid solutions that combine computer vision, with Artificial Intelligence, to form intelligent simulation models for corrosion detection in photovoltaic systems.

Conclusion

Computational sensing, with and without artificial intelligence, is transforming the way to assess the integrity of solar PV systems.In the context of global energy transition, protecting these assets against corrosion is a strategic necessity.

The integration of conventional algorithms with artificial intelligence in computational corrosion detection represents a breakthrough in solar system maintenance engineering, strengthening the sustainability and cost-effectiveness of PV installations in the face of challenging environmental conditions.

This article was developed by specialist Yolanda Reyes and published as part of the fifth edition of Inspenet Brief magazine August 2025, dedicated to technical content in the energy and industrial sector.