Galvanic isolation: Protection of assets against parasitic currents

Galvanic isolation can mitigate stray current corrosion, preventing electrical failures and ensuring the infrastructure's service life.

Galvanic isolation can mitigate stray current corrosion, preventing electrical failures and ensuring the infrastructure's service life.

Deep waste conversion increases the recovery of higher-value fractions and reduces coke generation.

Internal coating failure mechanisms and diagnostic approaches shaping AST tank integrity management through 2026.

Internal pipeline corrosion affects the integrity of industrial assets and is a costly process influenced by temperature and pressure.

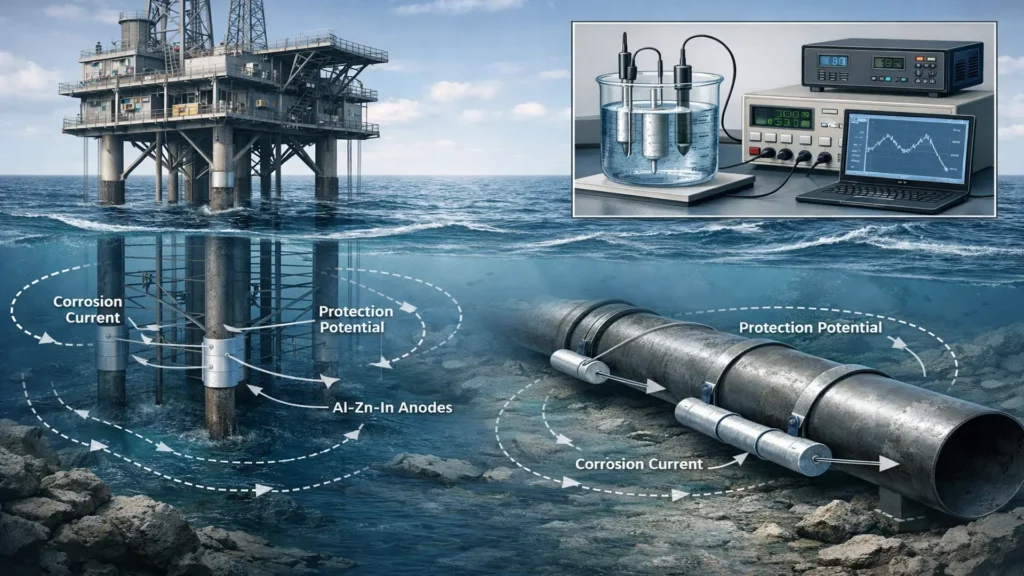

The NACE TM0190 standard defines the test for validating the electrochemical performance of aluminum anodes.

Intergranular corrosion compromises sensitized stainless steels; ASTM A262 allows for its detection and metallurgical control.

Crevice corrosion is an electrochemical mechanism of localized corrosion that compromises structural integrity.

Sacrificial anode control in marine infrastructure ensures effective cathodic protection, structural integrity, and extended service life in seawater environments.

Fractional distillation requires advanced control to operate efficiently and stably in refineries.

Failure analysis on metallic materials is a technical process that combines corrosion, fractography, metallography, and root cause diagnosis to identify the origin and progression of failures, enhancing the reliability and safety of industrial assets.

Spills continue to affect maritime safety and coastal ecosystems, requiring robust industrial preparedness and international technical cooperation to reduce operational impacts.

A vision of the role of engineering and human talent in the safe and efficient operation of offshore platforms.