The 2 key characteristics of Lean Manufacturing

Lean Manufacturing improves efficiency, reducing waste and optimizing resources throughout production.

Doctor in Administrative Sciences and management consultant with a solid background in Industrial Engineering, quality management and productivity engineering. His academic experience spans almost two decades, being a professor at various institutions and the author of books and numerous scientific articles in areas such as quality management, strategic foresight and business models.

Lean Manufacturing improves efficiency, reducing waste and optimizing resources throughout production.

Importance of ergonomics in control rooms to improve performance, safety, and well-being of personnel.

Effective innovative strategies and practices for engineering talent management to attract, retain and develop professionals in the digital age.

Impact of artificial intelligence on quality management and strategic business foresight.

The Kaizen strategy, based on continuous improvement, is applied to optimize processes, reduce waste and improve productivity.

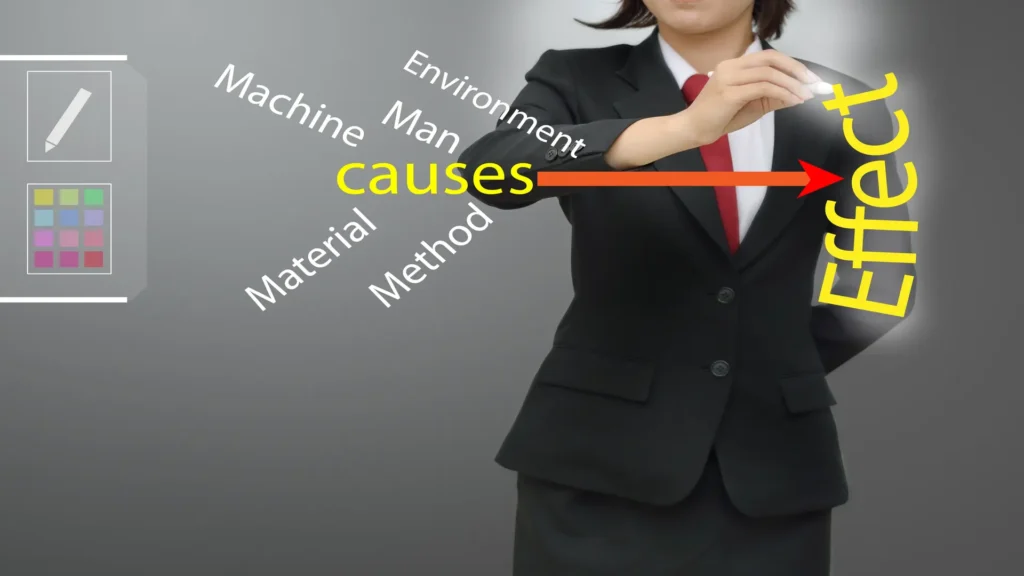

The Ishikawa Diagram: key in quality management and problem solving in organizations.

Exploring how Total Quality drives sustained success through the integration of processes, people, and technology.

Highlighting how agility in Quality Management Systems drives business competitiveness.

Incorporating climate change into ISO 9001:2015 to achieve sustainable business management.

The application of the 5S methodology is key to the operational optimization of warehouses.

Relation of ISO 9001 requirements to quality management principles.

Application of innovation management approaches in traditional industries.