Corrosion under insulation in AST tanks: Causes and solutions

Causes, detection, and solutions for corrosion under insulation in AST tanks to ensure safety and reliability.

Mechanical Engineer with specialization in industrial maintenance. 43 years of experience in the oil, petrochemical, gas, metalworking and food industries. Content developer, expert analyst in equipment and corrosion inspection and plant shutdown technical management. Qualified and certified in non-destructive testing techniques UT, PT, VT, MT, RT.

Causes, detection, and solutions for corrosion under insulation in AST tanks to ensure safety and reliability.

In extreme conditions, underwater inspection and structural monitoring enable the identification of signs of corrosion or fatigue in platforms and pipelines.

Thermal monitoring in industrial furnaces optimizes efficiency and safety by detecting early faults using infrared thermography and preventive maintenance.

Learn about API 510 best practices to ensure the integrity of pressure vessels in operation.

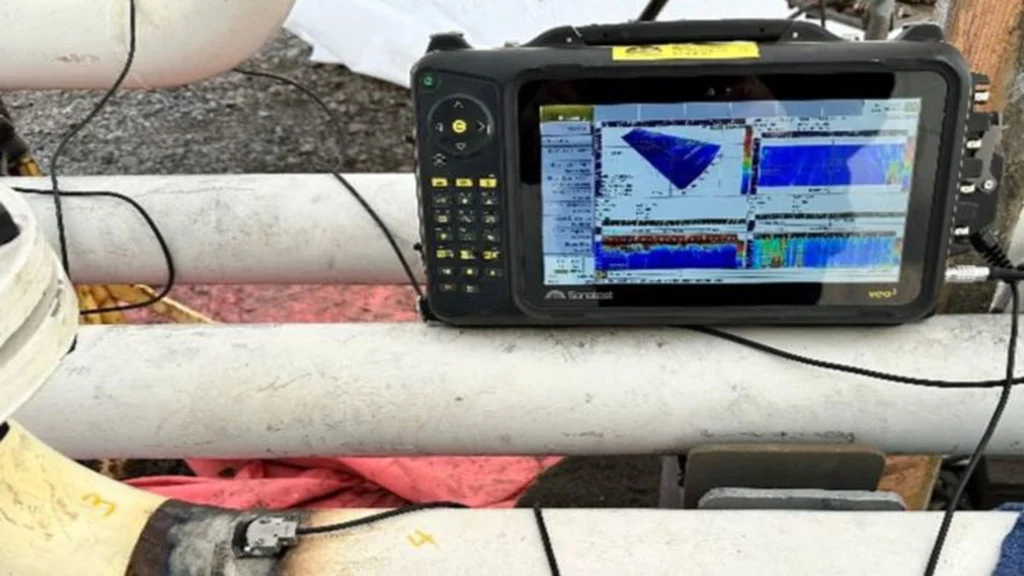

TFMi combines TFM and Full Matrix Capture for accurate, clear, and reliable ultrasonic inspections in critical industries.

API 500 guides electrical classification in hazardous oil and gas areas to ensure safety and protect equipment.

API 537 guides the safe and sustainable design of flare systems, optimizing combustion and reducing methane and VOC emissions.

Essential guide to API RP 936 for quality control and installation of monolithic refractories.

Digitalization drives operational efficiency, emissions reduction, and resilience in the downstream sector in the face of current energy challenges.

Pressure vessels are essential to industrial processes requiring pressure control and operational safety.

The structural integrity of industrial projects depends on avoiding welding defects; inspection being fundamental to prevent premature failures and ensure quality.

Filmogenic amines provide corrosion protection without physical coatings in aqueous systems.