Predictive maintenance in advanced asset management

Monitoring and predictive analytics application to anticipate failures and improve the performance of critical industrial assets.

Monitoring and predictive analytics application to anticipate failures and improve the performance of critical industrial assets.

The design of the system depends on the coating, soil resistivity and type of structure to be protected.

Recent advances that improve the operation of hydroelectric plants through automation, intelligent monitoring and digital systems.

Compliance with API standards reduces operational risks and improves the integrity of oilfield equipment.

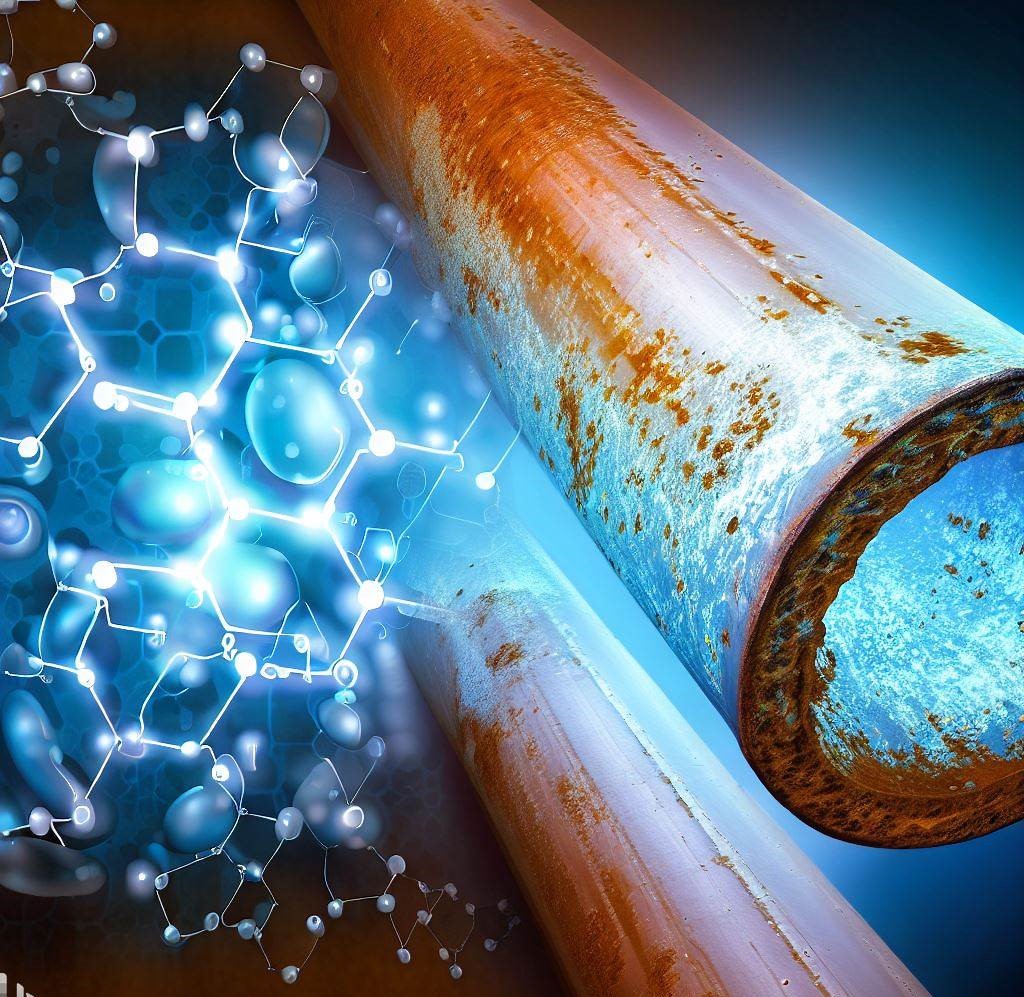

Nanotechnology applications allow the development of coatings that reduce corrosion rates and extend the life of metal structures.

MCC training strengthens asset management in companies seeking to increase reliability and optimize their resources.

Corrosion under insulation causes damage to equipment covered with insulating materials, caused by accumulated humidity, affecting several industries.

On April 20, 2010, the world witnessed the Deepwater Horizon disaster in the Gulf of Mexico.

Growing demand for renewable energy and fluctuating prices are driving the adoption of AI in the oil industry.

Internal and external corrosion compromises the integrity and operational efficiency of industrial pipelines.

The use of metallic nanoparticles reduces toxicity and improves the efficiency of industrial processes in the petrochemical industry.

The humanoid robots analyzed stand out for their mechanical and cognitive capabilities applied in industrial, social and research contexts.