Table of Contents

- Understanding High Temperature Hydrogen Attack (HTHA)

- Importance of early detection of HTHA

- Description of the High Sensitivity Fluorescent Wet Magnetic Particle Fluorescent Magnetic Particle Test (HSWFMT) technique

- Steps Involved in High Sensitivity Fluorescent Wet Magnetic Particle Assay for HTHA Detection

- Advantages of the High Sensitivity Wetted Fluorescent Magnetic Particle Method (HSWFMT)

- Considerations when applying the High Sensitivity Wetted Fluorescent Magnetic Particles (HSWFMT) technique for HTHA detection.

- Conclusions

- References

High Temperature Hydrogen Attack (HTHA) is a problem in the petrochemical and refining industry, where equipment is exposed to hydrogen at high temperatures and pressures. HTHA can lead to the formation of internal cracks and fissures, compromising the integrity of pressure vessels, reactors and pipelines. Early detection of HTHA corrosion is significant to ensure safety and prevent catastrophic failures.

One of the most effective methods for detecting this type of corrosion is the use of wet fluorescent magnetic particles in conjunction with the magnetic flux provided by the application of the magnetic particle test (MT) applied on a specially prepared surface to obtain the highest sensitivity.

Understanding High Temperature Hydrogen Attack (HTHA)

This atomic hydrogen attack process diffuses into steel at elevated temperatures, typically above 204 °C (400 °F). The hydrogen reacts with the carbon in the steel to form methane, which cannot diffuse out of the metal. This leads to the formation of internal cracks and fissures, weakening the material.

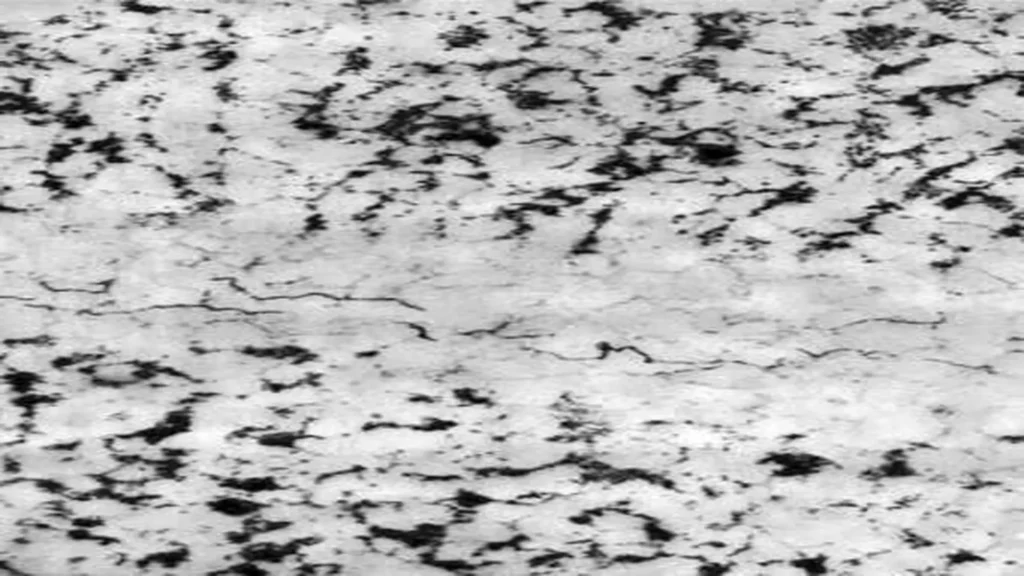

HTHA is often found in components of hydroprocessing units, such as hydrotreaters (desulfurizers) and hydrocrackers, catalytic reformers, some isomerization units, hydrogen production units and hydrogen stripping units1. Figure 1 shows a photomicrograph of hydrogen attack, image courtesy of Mistras Group.

Importance of early detection of HTHA

Early detection of HTHA is critical to prevent unexpected equipment failures. Traditional inspection methods, such as radiography (RT) testing, have limitations in detecting high-temperature hydrogen corrosion at the onset of the process. The ultrasonic testing method is currently the most widely accepted, however, for early detection of HTHA tends to be difficult and it is recommended to apply several different techniques to confirm the presence of this corrosion phenomenon.

The following video is a presentation of a refinery accident in the United States with disastrous consequences due to HTHA.

Vídeo de seguridad del accidente.

Magnetic particle testing, using wet fluorescent magnetic particles simultaneously with a magnetic flux and applied on a specially prepared surface with macroattack (HSWFMT), offers the highest sensitivity and is an effective solution for detecting surface and near-surface discontinuities caused by HTHA, serving as an ideal complement to verify the presence of previously detected near-surface patterns through advanced ultrasonic testing techniques such as Phase Array Ultrasonic Testing (PAUT), Total Capture Matrix/Total Focusing Method (FMC/TFM), both covered by API 941, and more recently Phase Coherence Imaging (PCI).

Description of the High Sensitivity Fluorescent Wet Magnetic Particle Fluorescent Magnetic Particle Test (HSWFMT) technique

Magnetic particle testing (MT) is a non-destructive testing (NDT) method used to detect surface and near-surface defects in ferromagnetic materials. The process involves applying a magnetic flux (magnetizing the component) and applying magnetic particles to the surface. The particles accumulate in areas of magnetic flux leakage, such as cracks and pores, making them visible under appropriate lighting conditions.

The highly sensitive wet fluorescent magnetic particle wet magnetic particle technique (HSWFMT) is a combination of surface metal removal, macroattack and direct magnetization technique2, i.e. by simultaneous application of magnetic flux and wet fluorescent magnetic particles.

Fluorescent magnetic particles applied simultaneously with magnetic flux (continuous magnetization) and the use of alternating current improve the visibility of defects under ultraviolet (UV) light, providing greater sensitivity compared to visible magnetic particles, and this sensitivity is maximized when applied on a macro-attenuated surface.

High sensitivity wet magnetic particle wet magnetic particle technique (HSWFMT) capable of detecting incipient, early stage and late stage HTHA damage randomly oriented on the inspection surface2.

Steps Involved in High Sensitivity Fluorescent Wet Magnetic Particle Assay for HTHA Detection

- Selection of areas to be inspected: Select those areas where typical HTHA patterns were previously detected near the surface by advanced ultrasound testing (PAUT, FMC/TFM or PCI).

- Surface preparation: Perform abrasive cleaning and then remove a layer of material. Subsequently, perform a macro-attack of the floor surface to be inspected.

- Magnetization: Select the direct magnetization technique by applying the magnetic flux simultaneously with the application of the particles and the use of alternating current.

- Application of Wet Fluorescent Magnetic Particles: Apply the suspension of wet fluorescent magnetic particles to the magnetized surface using a spray, flow or immersion method and simultaneously with the application of the magnetic flux.

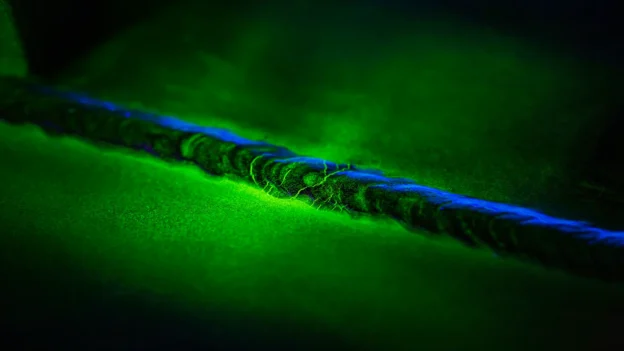

- Inspection under UV Light: Inspect the surface under UV light for any indication of magnetic flux leakage. Fluorescent particles will accumulate in areas of discontinuities, making them visible as glowing indications. A representative image of a wet fluorescent particle inspection is shown in Figure 2.

- Interpretation and evaluation: Interpret indications based on their size, shape and location. Evaluate indications according to relevant standards and acceptance criteria to determine the presence and severity of HTHA.

- Demagnetization and cleaning: After inspection, demagnetize the component to remove any residual magnetism. Clean the surface to remove any remaining magnetic particles.

Advantages of the High Sensitivity Wetted Fluorescent Magnetic Particle Method (HSWFMT)

The use of highly sensitive wet fluorescent magnetic particles offers several advantages for detecting HTHA:

- Increased sensitivity: Fluorescent particles provide increased sensitivity compared to visible particles, allowing the detection of finer discontinuities and especially on a surface prepared by material removal and macroattack.

- Improved visibility: The use of UV light improves the visibility of the indications, facilitating the identification and interpretation of defects.

- Improved coverage: Wet magnetic particles provide better coverage of irregular surfaces and complex geometries, ensuring complete inspection.

- Reduced background interference: Fluorescent particles reduce background noise and interference, leading to more accurate and reliable results.

Considerations when applying the High Sensitivity Wetted Fluorescent Magnetic Particles (HSWFMT) technique for HTHA detection.

Although magnetic particle testing with wet fluorescent particles is highly effective, there are certain challenges and considerations to keep in mind:

- Definition of the areas to be evaluated with HSWTMT: It is required to previously evaluate with advanced ultrasound techniques, preferably PAUT or FMC/TFM, to identify the areas that present typical patterns of HTHA indications, and from these mark those locations with indications on or near the internal surface of the component to verify with HSWFMT. Due to the internal dead zone indication provided by the ultrasonic TOFD technique, which can mask the presence of HTHA at or very close to the internal surface, it is not recommended to use it for this search when HSWFMT is contemplated.

- Surface condition: The maximization of the sensitivity of the test by first preparing the surface by abrasive cleaning (shot blasting provides the best cleaning) and then removing a layer of material (0.3 in. to 0.09 in. deep) using a fiber disc to a final finish of 80 to 100 grit. A picture of disc cleaning is shown in Figure 2.

- Surface macro-attack: Perform a macro-attack of the soil surface to be inspected. Three rounds of 5% Nital at 3-minute intervals are recommended for this purpose. Care should be taken to avoid excessive macro-attacking, as this may result in false positive indications2.

- Magnetization technique: To achieve maximum sensitivity, the type of magnetization current should be alternating and the magnetization direct, i.e. the particles should be applied simultaneously with the magnetic flux.

- Particle suspension: The concentration and quality of the magnetic particle suspension can impact the visibility of the indications. It is important to follow the manufacturer’s instructions for preparing and applying the suspension.

- UV light conditions: Adequate UV light intensity and proper inspection conditions are necessary to ensure the visibility of fluorescent indications. It is essential to verify that the light provided is class A (UV-A) as it is the safest from a health point of view. The intensity of the light should also be verified.

- Personnel qualification: To make the technique effective, it must be performed by technical personnel with a high degree of skill and training.

Conclusions

The detection of High Temperature Hydrogen Attack (HTHA) is crucial to ensure the safety and integrity of equipment in the petrochemical and refining industries. The Magnetic Particle (MT) testing method using the fluorescent wet magnetic particle technique applied simultaneously with magnetic flux and on a specially prepared surface (HSWFMT) offers an effective method to detect surface and near-surface discontinuities caused by HTHA.

By integrating steps such as macro-testing the polished surface prior to inspection and using fluorescent particles under UV light, inspectors can achieve greater sensitivity and accuracy in HTHA detection.

This method represents a tool by which equipment failures can be predicted and prevented. Implementing HSWFMT can significantly improve the reliability and safety of infrastructures exposed to high temperature hydrogen environments when the HTHA corrosion phenomenon develops on the internal surface of the component.

References

- AMERICAN PETROLEUM INSTITUTE. API Recommended Practice 571: Damage Mechanisms Affecting Fixed Equipment in the Refining Industries; Accessed May 27, 2024.

- AMERICAN PETROLEUM INSTITUTE. API Recommended Practice 941: Steels for Hydrogen Service at Elevated Temperatures and Pressures in Petroleum Refineries Petrochemical Plants; Accessed May 28, 2024.