Table of Contents

- Remote monitoring and IoT: advanced control of structural conditions

- Self-repairing coatings: Protection and reduced maintenance

- Advances in cathodic system materials and technologies

- Advanced simulation and modeling: smarter decisions

- Sustainable solutions: In cathodic protection systems

- Conclusions

- References

- Frequently Asked Questions (FAQs)

Cathodic protection is key to preventing corrosion in industrial infrastructure and ensuring the durability of metal assets. With constant technological evolution, cathodic protection systems have advanced toward more efficient, sustainable, and automated solutions.

In this article, we will explore the main trends in cathodic protection that every engineer, consultant, or project manager should know in order to maintain the integrity of their structures and optimize long-term maintenance costs.

Remote monitoring and IoT: advanced control of structural conditions

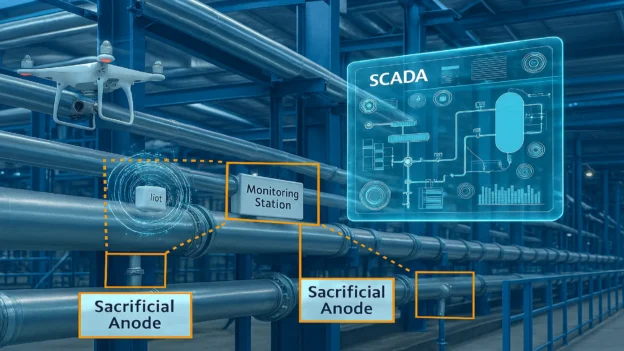

Digitization is transforming cathodic protection monitoring. Smart sensors, SCADA systems, and IoT platforms enable real-time monitoring, predictive analytics, and early fault detection.

The use of drones and underwater robots facilitates inspections in hard-to-reach areas, increasing personnel safety and reducing operating costs. This trend not only optimizes operational efficiency, but also allows for more accurate predictive maintenance, anticipating problems before they affect the integrity of the infrastructure.

Self-repairing coatings: Protection and reduced maintenance

Nanotechnology is opening a new chapter in corrosion protection. Nanocoatings, or polymer coatings on a nanometric scale, create a highly adhesive and self-repairing barrier that is resistant to the effects of salinity, humidity, and extreme temperature variations. These smart coatings are becoming strategic allies for infrastructure subjected to critical conditions, such as underwater pipelines, storage tanks, and offshore platforms.

Self-repairing coatings represent a technological advance in corrosion protection, representing advanced materials that can regenerate themselves in the event of microcracks or minor damage, maintaining the integrity of the structure without the need for frequent interventions. The result is a significant reduction in maintenance costs, greater asset durability, and optimized performance of the cathodic protection system.

Advances in cathodic system materials and technologies

The cathodic protection industry is undergoing significant evolution driven by materials science. New compositions of modified magnesium, zinc, and aluminum alloys are being introduced to improve current distribution and provide greater electrochemical uniformity in the protection of metal structures. These innovations reduce the tendency toward passivation and improve system stability even under conditions of high conductivity or severe environmental variations.

Thanks to these advanced alloys, cathodic systems achieve a longer operational life, reducing the frequency of anode replacement and optimizing maintenance costs. This approach increases energy efficiency and improves the sustainability of industrial operations.

Advanced simulation and modeling: smarter decisions

The use of numerical simulation and three-dimensional (3D) modeling tools is changing the way cathodic protection systems are designed, validated, and maintained. Thanks to these digital environments, engineers can anticipate the effects of corrosion, predict the electrochemical behavior of materials, and optimize the location and performance of anodes before actual installation.

Computational models, based on finite element methods (FEM) and fluid dynamics algorithms, accurately represent how protective currents are distributed over metal surfaces exposed to different environments, whether in buried pipes, marine structures, or storage tanks. This facilitates a deeper understanding of potential gradients, the influence of coating, and areas susceptible to overprotection or underprotection.

Predictive analysis, integrated with real-time monitoring data, allows complex scenarios to be simulated and different combinations of materials, geometric configurations, and current levels to be evaluated. This minimizes the risk of premature failure and ensures uniform protection throughout the system.

Furthermore, the integration of digital modeling with artificial intelligence (AI) is giving rise to systems capable of automatically adjusting protection parameters according to operating or environmental conditions. This convergence between simulation, AI, and remote monitoring strengthens predictive engineering, transforming cathodic protection projects into smarter, more sustainable systems that are aligned with international standards of quality and durability.

Sustainable solutions: In cathodic protection systems

Sustainability has evolved into a line of technological innovation within cathodic protection, driving the development of more autonomous, efficient, and environmentally responsible systems. One of the main trends is the integration of renewable energy sources such as solar and wind power into Impressed Current Protection (ICCP) systems, allowing protection potential to be maintained even in remote locations or those without connection to the electrical grid.

The use of photovoltaic solar panels, wind turbines, and smart hybrid controllers allows cathodic protection systems to be powered without relying on diesel generators or conventional power lines. This reduces the carbon footprint and increases system reliability and continuity, avoiding interruptions in the protective current caused by electrical failures or power outages.

These sustainable solutions represent a functional innovation, as they provide energy autonomy and continuous operation with minimal maintenance. In addition, modern systems include sensors and energy management algorithms that automatically regulate the power supply, ensuring an optimal balance between consumption and cathodic system efficiency.

At the same time, recycling materials and designing components with low environmental impact, such as recyclable anodes, eco-friendly polymer coatings, and modular structures, help extend the useful life of facilities and reduce industrial waste.

With these innovations, cathodic protection is moving towards a more eco-efficient, autonomous, and resilient model, where sustainability is not only an environmental goal but also a technological strategy that reinforces the reliability and performance of corrosion control systems.

Conclusions

Current trends in cathodic protection reflect a comprehensive evolution driven by technological innovation, sustainability, and digital intelligence. The incorporation of remote monitoring tools, advanced modeling, self-repairing coatings, and renewable energy sources is redefining how industries prevent and manage corrosion.

Innovations increase operational efficiency, reduce maintenance costs, and strengthen the safety and reliability of critical infrastructure. By adopting solutions based on data, smart materials, and clean energy, cathodic protection systems are moving toward a more autonomous, eco-efficient, and resilient model.

For project managers and leaders, staying up to date with these practices is essential to ensuring the long-term integrity of industrial assets, optimizing resources, and meeting global sustainability requirements. Ultimately, cathodic protection for the future not only protects steel, but also the environment, efficiency, and operational continuity of organizations.

References

- American Petroleum Institute (API). (2024). Guidelines for cathodic protection of pipelines. API Publishing.

- International Organization for Standardization (ISO). (2023). ISO 15589-1: Petroleum and natural gas industries — Cathodic protection of pipeline transportation systems. ISO.

- Dreiym. (June 11, 2024). Replantearse la protección del diseño catódico: tendencias actuales y mejores prácticas. https://www.dreiym.com/es/2024/06/11/replantearse-la-proteccion-del-diseno-catodico-tendencias-actuales-y-mejores-practicas/

- Inspenet. (2024). Latest Technologies in Cathodic Protection. https://inspenet.com/en/articulo/is-your-company-aligned-with-the-latest-technologies-in-cathodic-protection/

Frequently Asked Questions (FAQs)

What are trends in cathodic protection and why are they important?

Trends in cathodic protection include technological innovations, advanced materials, and digital monitoring that optimize corrosion prevention and reduce maintenance costs in industrial infrastructure.

How does remote monitoring and IoT help with cathodic protection?

Remote monitoring and IoT technology enable real-time supervision of structural conditions, early fault detection, and improved predictive maintenance efficiency in cathodic protection systems.

What benefits do high-energy anodes and self-repairing coatings offer?

High-energy anodes extend the service life and increase the efficiency of cathodic protection systems, while self-healing coatings reduce maintenance requirements and automatically protect against minor damage.

What role do sustainable solutions play in cathodic protection?

The use of solar and wind energy, together with recyclable and low-consumption components, enables cathodic systems that are more eco-efficient, sustainable, and have a lower environmental impact, especially in remote installations.