Table of Contents

- What is TFMi in ultrasonic inspection?

- Fundamentals of TFMi and its relationship with TFM

- TFMi vs Traditional Phased Array: Why is it superior?

- How does TFMi work?

- Technical benefits of TFMi

- In which industries is TFMi used?

- Digital integration and TFMi trends

- Use cases where TFMi offers clear advantages

- Why does TFMi support quality assurance standards?

- Source of experience

- Comparison between TFMi vs TFM vs Phased Array

- Capabilities across different materials

- Conclusion

- References

Not all ultrasonic inspection technologies achieve the same level of precision in critical industrial environments as TFMi, which combines TFM, Full Matrix Capture, and improvements over Phased Array to reveal internal defects with exceptional detail, generating sharper images and more intuitive evaluations, strengthening quality control and contributing in turn to greater operational safety.

In this article, you will discover how TFMi works, how it differs from traditional ultrasound, and why it is considered the next generation in the evaluation of industrial materials, establishing new standards in advanced inspection.

What is TFMi in ultrasonic inspection?

The term TFMi (Total Focusing Method – Intelligent) describes an evolution within TFM, where the technique processes the complete matrix of signals acquired through Full Matrix Capture. Each point in the inspection area is computationally focused, generating a millimetric acoustic map that enables the creation of ultrasonic images with higher precision, resolution, and sensitivity. It is based on the principle of the Total Focusing Method but incorporates algorithmic improvements and additional propagation modes to deliver a more realistic acoustic map with reduced noise.

TFMi is based on:

- Full Matrix Capture (FMC): full acquisition of acoustic responses between all array elements.

- Intelligent processing: prioritizes relevant wave modes and optimizes defect representation.

- Single composite image: combines multiple modes to reduce subjective interpretations.

In practice, this means that a small, inclined, or low-contrast discontinuity can be revealed in greater detail, even in complex materials such as austenitic stainless steels, nickel alloys, or composite materials used in aerospace.

Fundamentals of TFMi and its relationship with TFM

Although TFMi derives from TFM, it should not be considered a simple refinement. It is a technological leap that addresses two challenges of industrial ultrasound:

- Greater reliability in interpretation: TFMi produces a clearer image with less structural noise, favoring early defect detection.

- Reduction of evaluation time: By generating a single integrated image, it reduces the need to compare multiple propagation modes.

Table 1. Technical differences between TFM and TFMi

| Characteristic | TFM | TFMi |

|---|---|---|

| Database | FMC | Optimized FMC |

| Modes used | 1 mode per image | Combination of multiple modes |

| Interpretation | Requires experience | More intuitive |

| Sensitivity | High | Higher |

| Background noise | Moderate | Reduced |

TFMi vs Traditional Phased Array: Why is it superior?

- Phased Array (PA) has been one of the most widely used methods for two decades. However, its limitations have become more evident in complex components or those with unconventional geometries.

- TFMi addresses these limitations with images of greater precision without depending on dynamic focal laws.

- Greater spatial resolution thanks to dynamic pixel-by-pixel focusing.

- Simpler preparation, as it does not require complex configurations.

- Less operator variability, which increases repeatability.

- Multimodal reconstruction, allowing the detection of defects that Phased Array may overlook.

- Better performance in materials with attenuation or anisotropy.

Table 2. Comparison TFMi vs Phased Array

| Parameter | Phased Array | TFMi |

|---|---|---|

| Acquisition type | Focal laws | Full FMC (digital pixel-by-pixel focusing) |

| Spatial resolution | Good | Excellent |

| Precision in complex geometries | Limited | High |

| Sensitivity to small defects | Medium | Maximum |

| Operator requirements | More experience | Less experience |

| Visualization | Amplitude-based | Image-based |

| Application | General | Critical or high reliability |

| Wave modes | One main mode | Multiple modes simultaneously |

| Setup complexity | High | Low |

| Repeatability | Variable | Uniform |

TFMi surpasses conventional PAU in virtually all relevant criteria for critical inspection.

How does TFMi work?

TFMi operates through an optimized sequence of acquisition, processing, and visualization of ultrasonic signals that enables the reconstruction of a high-fidelity composite image. The process begins with data capture based on Full Matrix Capture, in which each element of the ultrasonic array sequentially acts as both transmitter and receiver. This strategy generates a complete matrix of raw data containing all possible combinations of acoustic paths, providing an exhaustive basis for characterizing the inspected material.

Once the FMC matrix is obtained, intelligent processing begins. In this phase, the algorithm analyzes the acoustic content and selects the most useful propagation modes, such as longitudinal-longitudinal (LL), transverse-transverse (TT), and combined (LT and TL). This selection not only improves the signal-to-noise ratio but also reduces false artifacts and decreases the dependence on the operator’s interpretive skills, enabling a more robust and repeatable evaluation.

Subsequently, the composite image rendering occurs, where TFMi fuses the selected modes into a single visual representation. This integration eliminates the need to review multiple independent channels and offers a more intuitive interpretation, as the inspector works with a consolidated image that more accurately reflects the distribution and morphology of present discontinuities.

Technical benefits of TFMi

TFMi technology provides greater sensitivity by enabling the detection of smaller defects and improving the identification of incipient cracks. Its performance is particularly superior in complex geometries such as nozzles, welded joints, forgings, and pipes with internal wear, where other methods show limitations. The reduction of human error is another key benefit, since image-based interpretation reduces the need for signal magnification and improves analysis repeatability. This visual approach standardizes evaluation among inspectors and facilitates traceability.

The method also optimizes inspection time, as it requires fewer operational configurations and allows faster evaluations without compromising diagnostic quality. Additionally, TFMi remains compatible with industrial procedures based on conventional ultrasound, phased array (PA), and TFM, which facilitates its integration into existing inspection routines.

In which industries is TFMi used?

TFMi is applied in sectors where structural integrity is a critical requirement. In the energy industry, including oil, gas, and petrochemical, it is used to inspect piping, welded joints, and areas susceptible to internal corrosion. In the naval and offshore sectors, the technique is particularly useful for examining structures with complex geometry or components made from stainless and duplex steels.

The power generation industry uses it in boilers, turbines, and heat exchangers, where early detection of discontinuities is essential to avoid catastrophic failures. In aerospace, TFMi contributes to the inspection of high-performance alloy components and composite materials. Mining, metallurgy, and advanced manufacturing also adopt it for the evaluation of forgings, thick components, and parts subject to strict tolerances within quality control programs.

Digital integration and TFMi trends

One of TFMi’s main strengths is its ability to integrate with digital ecosystems for predictive maintenance. Current connectivity enables the export and analysis of complete FMC matrices in advanced evaluation software platforms, expanding the reach of analysis beyond the inspection field. The technique adapts to automation through robotic arms, inline inspection systems, and intelligent reporting platforms that facilitate digital traceability.

Artificial intelligence applied to ultrasound complements this progress. Although AI does not replace the operator, it provides assistance through automatic indication detection, pattern recognition, and reduced subjectivity in interpretation. This opens the path to more consistent methodologies and data-based decision-making processes.

Use cases where TFMi offers clear advantages

TFMi is particularly effective in complex weld geometries, such as those found in pipes with extensive heat-affected zones, dissimilar welds, or joints with abrupt thickness changes. Its ability to integrate multiple acoustic modes into a single image allows it to overcome the limitations of traditional techniques, providing greater clarity in identifying hidden discontinuities.

In the context of corrosion under insulation, TFMi facilitates the evaluation of corrosion maps with better definition, especially when using wheel-type probes or scanners designed for continuous movement. Its advantage is also evident in the inspection of components with limited access, where the integrated image reduces the need for multiple configurations, increasing efficiency without sacrificing precision.

Why does TFMi support quality assurance standards?

The image-based approach enables faster audits, improves process standardization, and reduces dependence on the operator’s subjective judgment. Findings can be documented visually, facilitating review by integrity teams, quality assurance departments, and regulatory bodies. This visual and verifiable capability increases confidence in the results and strengthens compliance with technical standards.

Source of experience

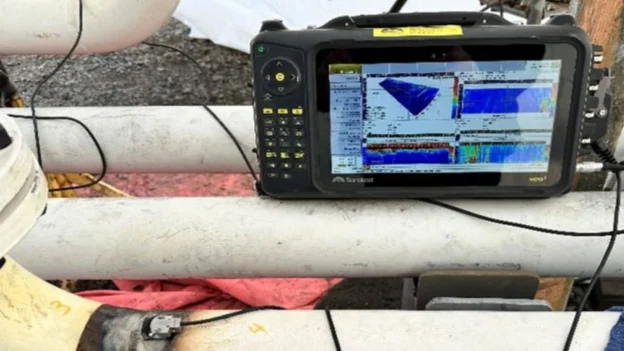

Several manufacturers have contributed to the development and refinement of TFMi. Among them is Sonatest, whose extensive experience in industrial ultrasound has driven improvements in the practical use of FMi, the application of FMC, the management of multiple modes, and integration with automated systems. Their contributions have helped consolidate TFMi as an advanced tool with tangible benefits in industrial inspection.

Comparison between TFMi vs TFM vs Phased Array

Table 3. Comparison between Phased Array, TFM, and TFMi

| Criteria | Phased Array | TFM | TFMi |

|---|---|---|---|

| Base technology | Focal laws | FMC + TFM | FMC + enhanced TFM |

| Image | Amplitude-dependent | Good | Excellent |

| Composite modes | No | Limited | Yes, multiple modes |

| Interpretation | More subjective | Medium | High and simplified |

| Complex geometries | Challenging | Better | Optimal |

| Inspection cost | Medium | High | Medium-high (higher precision) |

| Industrial application | General | Critical | Critical and advanced |

Capabilities across different materials

Table 4. Performance comparison across materials

| Material | Phased Array | TFMi |

|---|---|---|

| Austenitic stainless | High structural noise | Better penetration and clarity |

| Titanium | Moderate attenuation | Cleaner image |

| Nickel alloys | Complex diffraction | Improved detection |

| Composites | Difficult for PA | Efficient multimode reconstruction |

Conclusion

TFMi technology represents a significant leap within ultrasonic inspection, combining the precision of TFM, the data richness of Full Matrix Capture, and more intuitive visualization. Its advantages in complex geometries, sensitivity, and reduction of subjectivity position it as an emerging standard for critical industrial sectors. With the growth of automation and digital integration, TFMi will continue expanding its presence and improving the reliability of inspections based on industrial ultrasound.

References

- Sumana, S. & Kumar, A. (2021). Total Focusing Method-Based Ultrasonic Phased Array Imaging in Thick Structures. Journal of Nondestructive Evaluation, Diagnostics and Prognostics of Engineering Systems, 4(4), 041005. DOI: 10.1115/1.4050802 https://pureportal.strath.ac.uk/en/publications/total-focusing-method-based-ultrasonic-phased-array-imaging-in-th

- Wang, Y., Li, Y., Bu, Y., Dong, S., Wei, H. & Cheng, J. (2024). Research on Region Noise Reduction and Feature Analysis of Total Focus Method Ultrasound Image Based on Branch Pipe Fillet Weld. Applied Sciences, 14(21), 9737. DOI: 10.3390/app14219737. https://www.mdpi.com/2076-3417/14/21/9737

- “Intermodal Total Focusing Method (TFMi™) and Multi-technique Ultrasonic Sizing Analysis Study,” Sonatest. Technical publication with comparative metrics between TFMi, TFM, TOFD, and phased array. https://sonatest.com/application/files/1817/3712/8666/P018-TFMi-Multi-Technique-Ultrasonic-Sizing-Analysus-Study.pdf