Introduction

Keeping the integrity of gas, oil, and water pipelines under control represents a serious technical problem when these infrastructures are located in remote areas that are difficult to access or in highly congested urban environments. Only a remote monitoring system for cathodic protection can efficiently assess their condition and act in a timely manner if necessary.

If, in addition, the area is exposed to stray currents, the challenge becomes even more complex and an efficient remote monitoring system for cathodic protection becomes essential. However, implementing the right solution allows you to work with greater precision and confidence.

What is remote cathodic protection monitoring?

Remote monitoring of cathodic protection (RPM) is a technique that uses sensors, software and communication systems to monitor the effectiveness of cathodic protection (CP) systems remotely, without the need for on-site inspections. This allows detecting anomalies, failures and adjusting the CP system remotely, optimizing its efficiency and prolonging the life of the protected structures with respect to a traditional cathodic protection monitoring system.

Millions of kilometers of subway metallic pipelines, distributed throughout the world, constitute essential corridors for the transport of fluids such as oil derivatives, natural gas, water and wastewater, among others.

This network infrastructure is constantly exposed to corrosive threats, either from contact with the surrounding soil or from electrical interactions with nearby facilities, such as power transmission lines, power trains or cathodic protection systems of other adjacent pipelines.

The following is a video courtesy of MOBILTEX – CorTalk, an IoT technology for remote asset monitoring using industry-leading data collection, transmission, and analysis platforms. This results in greater operational efficiency, increased data reliability and infrastructure integrity.

Online monitoring of pipeline assets with IIoT (Industrial Internet of Things) technology.

Wireless remote monitoring and control of cathodic protection systems

One of the fundamental aspects in the operation of cathodic protection (CP) systems is to ensure proper operation to guarantee protection that provides control over pipelines and reduce the incidence of corrosion. Currently, the proposed systems integrate wireless sensor network (WSN) technology to collect potential data and perform remote data transmission.

In this system, each WSN receives data from the environment and forwards it to a remote terminal unit (RTU). Then, each RTU forwards it to its base station (BS), by monitoring data, in order to obtain optimal results, less time delay and high speed to avoid corrosion.

Wireless cathodic protection monitoring helps extend asset lifespan, reduce downtime, lower operational costs, and protect the environment from leaks and spills. Additionally, in many industries, collecting and reporting CP operational data is a regulatory requirement.

Although the oil and gas industry has used CP systems for decades, automating their monitoring, data collection and control through wireless devices is a relatively recent addition. Without this technology, technicians must physically travel to each rectifier and test point to verify operation and perform periodic manual measurements of the potential between the pipe and the ground.

With companies currently managing extensive pipeline networks, these inspections may only be carried out once or twice a year, leading to significant data gaps. This means that if a CP system fails, the problem could go undetected for months, exposing the infrastructure to corrosion. In addition to the cost and time involved, these visits involve risks associated with weather, travel to remote areas, and exposure to electrical hazards. Specialized personnel must interrupt maintenance and optimization work to dedicate themselves to laborious and inefficient inspections.

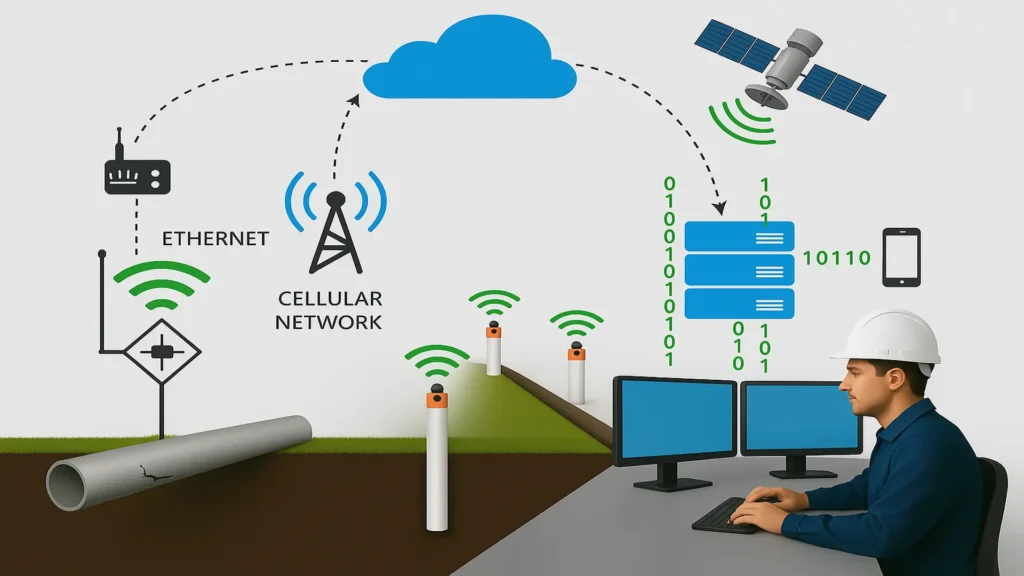

The operational flow can be described as follows:

- Local transmission: Acquired data is sent from each monitoring unit (such as transmission poles) via wireless (Wi-Fi, LoRa, etc.) or wired (Ethernet) technologies to a local concentrator or gateway.

- Remote network link: From the concentrator, the information is transmitted through a cellular or satellite network, depending on the location and available coverage. The image shows the connection to the cloud through:

- Cellular Network: use of telecommunication towers.

- Satellite links: alternative for areas without terrestrial infrastructure.

- Cloud storage and processing: Data are hosted on remote servers or cloud platforms, where they are processed using analytical algorithms to identify deviations, critical conditions or risk events.

- Field data acquisition: Sensors installed at key points of the cathodic protection system (such as test points, rectifiers or reference cells) record critical parameters such as electrical potential, current and system status.

- Remote visualization and control: Technical personnel can access information through graphical interfaces on monitoring stations or mobile devices. This real-time visualization allows timely decisions to be made for maintenance or adjustment of the CP system.

Factors to consider when choosing a remote monitoring system for CP

Selecting an efficient remote monitoring system involves considering multiple variables. A malfunction not detected in time can seriously compromise the integrity of the network. Three factors are critical:

- Flexibility: These devices must offer multiple connectivity options: mobile, cable and satellite communication, allowing them to operate even in areas with limited coverage; guarantee fast, secure and easy access to data; and integrate seamlessly with pre-existing systems, expanding their operational capacity.

- Maintenance: Modern systems using technologies such as the Digital Twin, which virtually replicates the facility in real time, allow continuous monitoring of the structural condition and simulate operational scenarios. The integration of remote monitoring data, weather conditions, can anticipate failures, optimize operations and apply predictive maintenance. This allows you to: Minimize unplanned shutdowns, strategically allocate maintenance resources and increase operational safety.

What are the advantages of remote monitoring of cathodic protection?

The importance of remote monitoring lies in its benefits, which are discussed below:

- Real-time measurements: An advanced system allows measurements to be taken every second, all day long, 365 days a year, capturing details impossible to obtain through manual inspections.

- Accurate anomaly detection: Data analysis allows rapid identification of specific faults: from rectifier downtime to anode resistance variation or damage to unidirectional drains, speeding up corrective interventions and optimizing maintenance programs.

- Electrical interference mitigation: In areas affected by stray currents, continuous remote monitoring can capture critical conditions that might go undetected in brief inspections. Simultaneous measurement of ON potential, IR-free and alternating currents is key to assessing regulatory compliance and the effectiveness of mitigation devices.

Technological innovations in CP remote monitoring

New wireless technologies make it possible to visualize multiple variables, automate analysis and generate alarms. The more sophisticated the system, the higher the quality of the data obtained and the more efficient the management of the CP system, reducing on-site inspections to those strictly necessary.

Systems such as Automa’s WebProCat, in conjunction with ultra-low power devices, allow up to 48 months of continuous operation without external power.

Digitization has profoundly transformed the implementation and management of CP systems. Smart sensors, SCADA systems and real-time analytics improve monitoring accuracy. The use of drones and underwater robots facilitates inspections in inaccessible areas, reduces risks and prevents costly failures.

Companies like Mobiltex integrate IIoT (Industrial Internet of Things) technologies to extend asset life, preserve public safety and minimize environmental impact. Equipment such as the RMU2 enables constant monitoring of water and fuel pipelines, even beyond corrosion. Below are the remote transmission products of this company, where you can see how they work.

Devices with remote wireless technology.

Advanced remote monitoring technologies and smart integrations

In addition to the use of acquisition units installed at critical sites, today’s remote monitoring system has evolved into highly integrated solutions with real-time transmission capabilities. These technologies allow:

- Synchronized ON/OFF readings for instantaneous structure potential measurements.

- Remote control of rectifiers, including voltage/current adjustment and synchronized interruption scheduling.

- Automatic alerts for deviations in protection potentials, communication failures, power loss, or unauthorized access.

- Secure web platform access with trend visualization, customizable reports, and compatibility with international standards (such as NACE SP0187 and SP0502).

The system can operate in both unidirectional (read) and bidirectional (read and control) modes, using cellular, satellite or long-range communications, making it an essential tool for operators managing geographically dispersed pipeline networks.

Conclusions

Cathodic protection remains a fundamental barrier against corrosion in pipelines and buried pipelines, but its effectiveness depends directly on continuous operational control. The implementation of remote monitoring systems for cathodic protection transforms reactive maintenance into a predictive strategy, minimizing failures, optimizing resources and extending asset life.

In an era where connectivity and data are strategic, adopting advanced monitoring technologies is not an option, but a necessity. Companies that integrate intelligent solutions into their integrity programs not only comply with regulations, but also lead in efficiency, sustainability and operational reliability.

Is your infrastructure ready to take the next step? Remote monitoring is no longer the future, it’s the standard.

References

- NACE International. (2018). SP0169-2013: Control of External Corrosion on Underground or Submerged Metallic Piping Systems. Houston, TX: NACE.

- Revie, R. W., & Uhlig, H. H. (2008). Corrosion and Corrosion Control (4th ed.). Hoboken, NJ: Wiley.

- Villalobos, J. R., & Cornejo, J. M. (2021). Monitoreo remoto en sistemas de protección catódica: fundamentos, tecnologías y aplicaciones. Revista de Integridad de Activos, 9(3), 45–58.

- Yan, X., Wu, M., & Zhang, W. (2020). Remote Monitoring Systems for Cathodic Protection: State-of-the-Art Review. Journal of Pipeline Engineering, 19(2), 85–93.