Introduction

Natural gas compression offers significant benefits for the economy and energy sustainability. Natural gas compression systems facilitate the transportation of gas over long distances through pipelines, enabling distribution to remote regions, reducing dependence on other energy sources, and promoting the use of natural gas as a cleaner and more efficient alternative.

Currently, a range of technological innovations is being developed to enhance the gas compression process according to plant requirements, ensuring a steady flow, electricity generation, and energy security.

The objective is to provide a comprehensive overview of how new technologies are transforming gas compression processes and contributing to environmental impact mitigation. Recent technological innovations in this field will be highlighted, analyzing the advantages and benefits they offer, including their environmental impact, focusing on emissions reduction, increased energy efficiency, and sustainability in the natural gas industry.

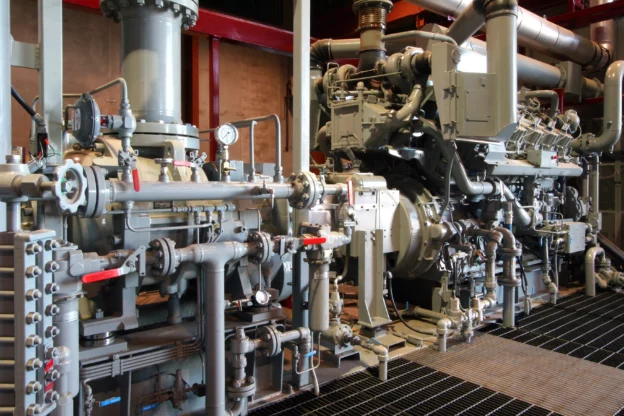

Natural gas compression process

Compression can be represented by a thermodynamic process, where the gas at pressure P1 is compressed and then discharged at a higher pressure P2. This process can occur in one or multiple stages. Figure 1 depicts a simplified diagram of this process1.

The gas from the source enters a heat exchanger where its temperature is reduced from T1 to T2. As a result of this temperature decrease, condensation of certain compounds may or may not occur. In cases where condensation occurs, it is necessary to place a separator, from which two streams emerge: a gas stream at the top and a liquid stream at the bottom. The gas stream is sent to the compressor, where the pressure is increased from P2 to P3, resulting in a temperature increase from T2 to T3. The gas stream exiting the compressor at T3 enters a heat exchanger and exits at a lower temperature T4. This gas stream, with some liquid content, is sent to a separator, from which two streams emerge: a gas stream at the top and a liquid stream at the bottom. This process ensures the gas volume meets the required pressure and temperature conditions for the process.

New technologies in natural gas compression systems

Continuous innovations in the field of natural gas compression are leading to emerging trends that are transforming the industry:

- Use of advanced technologies: The integration of emerging technologies such as artificial intelligence (AI), Internet of Things (IoT), and data analytics is optimizing the performance of compression systems. This enables real-time monitoring, early fault detection, and predictive maintenance, improving operational efficiency. For example, Supervisory Control and Data Acquisition (SCADA) systems.

- Development of oil-free compressors: The industry is progressing towards the use of compressors that do not require oil for operation, reducing gas contamination from lubricant residues and lowering maintenance costs. These compressors are more environmentally friendly and suitable for critical applications requiring high-purity natural gas.

- Cryogenic compression: This technology is applied to maintain specific gas conditions at extremely low temperatures, reducing energy consumption and enhancing compression process efficiency.

- Focus on decarbonization: New trends are centered around decarbonizing natural gas compression systems. This includes developing compressors powered by renewable energies such as wind or solar power to reduce the carbon footprint associated with gas compression.

- Advanced compression technology: Innovative compressor designs are engineered with cutting-edge principles to enhance efficiency and performance. They incorporate features like variable speed drives, advanced rotor geometries, and optimized cooling systems to improve energy efficiency and operational flexibility.

- Next-generation compression systems: These systems integrate advanced monitoring and control technologies to optimize performance and reduce downtime. Real-time data analysis, predictive maintenance algorithms, and remote monitoring capabilities enable proactive maintenance and issue resolution, ensuring optimal system operation and reliability.

- Advanced emission control technologies: Such as low-emission combustion systems and exhaust gas treatment systems, help mitigate greenhouse gas emissions and air pollutants, aligning with strict environmental regulations and sustainability objectives.

Benefits of technological innovations in the compression process

Below are the benefits that positively impact the natural gas industry:

- Energy efficiency: New technologies applied to compression systems enable improved efficiency in natural gas compression, reducing energy losses and optimizing resource consumption. This translates to more cost-effective and sustainable gas transportation.

- Emission reduction: Implementing innovations in natural gas compression significantly contributes to reducing pollutant emissions. Technologies like next-generation compressors minimize the release of greenhouse gases, helping mitigate environmental impact.

- Increased reliability and safety: Technological improvements ensure more reliable operation of compression systems, reducing downtime and enhancing operational safety. This results in more effective and secure natural gas distribution throughout pipelines.

- Adaptability to market demands: Innovations allow for greater flexibility in responding to energy market demands. Enhanced compression systems adjust quickly to changes in gas flows and distribution requirements, optimizing network capacity.

Future perspectives in natural gas compression processes

Technological innovations in natural gas compression systems promise significant advances in efficiency and sustainability. New technologies in compressors and gas station design emphasize improvements in efficiency and reliability through the use of advanced materials and enhanced lubrication technologies.

Gas compressors are being designed to be more compact and efficient, while gas stations are being integrated and automated to enable remote and efficient operations management. Automation and dynamic simulation models play a crucial role in optimizing gas compression, allowing for real-time adjustments to maximize operational efficiency and minimize energy consumption.

Engineering design is advancing to meet market demands, with modular and sustainable approaches that minimize emissions and optimize resource consumption. The growth of the natural gas compression market is driven by increasing demand for clean and efficient energy, with innovative solutions being adopted across various industries.

This growth is expected to continue, propelled by the need to reduce emissions and promote energy sustainability. Together, these trends and technological advancements shape the future of natural gas compression processes, emphasizing efficiency, sustainability, and innovation across the gas value chain.

Conclusion

The future of the natural gas industry is shaped by technological innovations as companies strive to offer customers efficient, cost-effective, and sustainable compressor station solutions. By adopting these innovations, the industry can enhance its operational capabilities, reduce environmental impact, and maintain its position as a key contributor to the global economy.

References

- Morales, P Fernando; “Natural Gas Compression and Expansion Processes”; 2001