Introduction

Welding is an indispensable process in industrial manufacturing, where materials are joined to create solid and functional structures. GMAW (Gas Metal Arc Welding), also known as MIG (Metal Inert Gas) welding, has revolutionized the manufacturing industry thanks to its high efficiency, versatility, and capacity for welding automation. This article explores how MIG welding has transformed manufacturing processes, highlighting its methods, characteristics, and applications in various industrial sectors.

What is MIG welding?

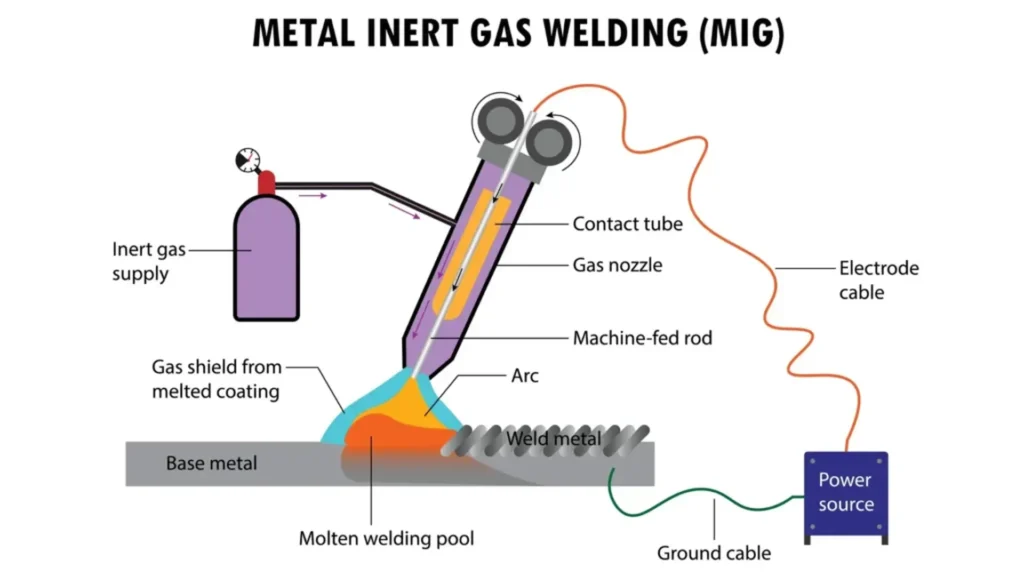

It is an electric arc welding process that uses a continuous wire consumable electrode and an inert gas that protects the weld zone from atmospheric contamination. In this process, the electric arc is formed between the welding wire and the work piece, melting the wire and the base material to create the weld. The protection provided by the inert gas prevents oxidation and other chemical reactions that could compromise the integrity of the weld.

What is MIG Welding?

The principle of MIG welding

Is a versatile technique suitable for thick and thin section components. During the process, an electric arc melts the surface of the base materials (materials or workpieces to be welded) to form a molten pool which is then cooled to form a strong joint and join the metals together. During welding, the welder continuously supplies a consumable heated wire electrode and shielding gas through a welding torch. To carry out the welding process, the welder continuously supplies a consumable heated wire electrode and shielding gas through a welding torch.

Gas-shielded metal arc welding uses a filler wire as the electrode, with the shielding gas flowing out of the nozzle at a certain speed. This isolates the welding wire melted by the arc, the molten weld pool and the nearby weld metal from the air, avoiding its harmful effects to obtain a good quality weld bead. A representative image of the MIG welding process is shown below.

Classification of MIG processes by degree of automation

- Semi-automatic: Processes where the human operator has direct control over the gun and must adjust the welding parameters, while wire and gas feeding are automatic. Commonly applied in small and medium-sized workshops, repair, and fabrication jobs where flexibility and human skill are required.

- Automatic: Includes systems where the welding gun is moved by automatic equipment, such as carriage welders or welding automation systems mounted on stationary machines. Used in production lines and mass production where high consistency and speed are required.

- Robotic: Involves robots programmed to perform repetitive welds with high accuracy and consistency, typically in mass production environments. Common use in automotive, aerospace component manufacturing and other high production applications where extreme precision and high repeatability are required.

Methods of MIG welding

They are classified according to the type of material, welding position and application as follows:

Conventional MIG (conventional GMAW):

- This is the most basic and common MIG welding process, where an inert gas such as argon or a mixture of gases is used. Ideal for welding non-ferrous metals such as aluminum, copper and nickel alloys.

- Pulsed MIG (GMAW-P): Alternates between high and low currents, creating a pulsed arc. Allows better control of heat and filler material transfer. Useful for welding thin metals and reducing spatter. Ideal for heat-sensitive materials and out-of-plane welding positions.

- High-speed MIG (GMAW-HS): Higher current and wire feed speed than conventional MIG is used, allowing faster electric arc welding. Suitable for industrial applications where high productivity is required, such as automotive manufacturing.

- MIG with Short Circuiting Transfer: Transfer of the filler material occurs through a repeated short circuit. This generates a relatively cold electric arc. Ideal for welding thin metals in all positions. It is common in the construction industry and in repair work.

- MIG with Globular Transfer: The filler material is transferred in the form of large droplets. This process produces more spatter and a hotter arc. It is not preferred due to the high amount of spatter, but can be useful for thick welds in flat positions.

- Spray Transfer MIG: The filler material is transferred in the form of small, fine droplets. This process generates a very hot and stable arc. Ideal for welding thick materials in flat and horizontal positions. Not recommended for thin materials due to high penetration and risk of burns.

- Double Pulsed MIG: Combines the pulsed MIG process with a second pulse for greater control of the weld pool. It is used in applications where high weld quality and precise heat control are required, such as aluminum and stainless steel welding.

Equipment needed for a MIG welding process

Commonly, a DC welding machine is used for MIG welding, but in some cases, an AC power source can also be used.

- Power source (MIG welding machines): Provides direct current (DC) to create and maintain the electric arc.

- Welding wire: Acts as the filler material that is melted to form the weld. Generally, it comes on spools with the wire coiled.

- Wire feeder: Provides a continuous and controlled supply of wire, which is melted in the electric arc and deposited in the weld pool.

- Welding gun: Delivers the wire and shielding gas to the weld zone.

- Shielding gas: Protects the arc and weld pool from atmospheric contamination. It is usually pure argon or mixtures of argon with helium.

- Preparation: Cleaning and preparation of the surfaces to be welded.

- Cooling system (optional, for high power applications): Maintains the welding gun at a safe operating temperature.

- Gas regulator: Controls the shielding gas flow.

- Gas cylinder: Stores and supplies the shielding gas.

- Pressure gauges: Used to measure gas pressure and flow.

Comparison of MIG welding with other welding methods

MAG (Metal Active Gas) welding: This method is similar to MIG welding. The difference lies in the type of shielding gas used, where MIG uses inert gas

such as argon or a mixture of argon and helium that do not react chemically with the base material or filler metal. MAG uses active gases such as carbon dioxide (CO2) or a mixture of CO2 and argon, which can react with the base material and filler metal that can influence the properties of the weld.

TIG welding: TIG welding, or tungsten inert gas welding, is known for its precision and superior quality. Unlike MIG welding, TIG welding uses a non-consumable tungsten electrode and can be used with or without filler metal. Although it produces high quality welds, TIG welding is slower and requires greater operator skill, making it less suitable for mass production applications.

SMAW welding: Shielded arc arc welding (SMAW) is another commonly used method. This process employs a coated electrode that produces its own shielding gas as it melts. Although versatile and portable, SMAW produces more slag and requires more post-weld cleanup compared to MIG welding. It is also less efficient.

Problems related to MIG welding

The most common problems with this process are the following:

- Porosity due to shielding gas contamination: any contamination in the gas (such as moisture or oil) can cause porosity. This problem is more specific to MIG welding and other processes that use shielding gas (such as TIG), but is less common in gasless processes such as SMAW (Stick Welding).

- Excessive spatter: MIG welding tends to produce more spatter compared to other methods such as TIG. Excessive spatter can be caused by incorrect voltage and current settings, or the use of improper shielding gas.

- Problems with the wire feed: Wire feed can exhibit jams, tangles and feeding. These problems are unique to processes that use continuous feed wire, such as MIG welding.

- Oxidation and discoloration: This usually occurs when there is insufficient gas coverage in the weld puddle.

- Arc starting problems: In MIG welding, arc starting can be problematic if the wire does not make proper contact or if there are problems with the machine setup. This is specific to processes using a continuous wire.

- Wind sensitivity: Shielding gas is very sensitive to wind currents and can be affected by that, so welding should be done in protected areas.

- Nozzle wear: Continuous use can cause wear on the welding gun nozzle, requiring regular maintenance.

Conclusion

MIG welding has revolutionized manufacturing processes by offering a fast, efficient and versatile solution for joining materials. Its ability to Welding automation by integrating automated, and robotic systems has enabled industries to improve productivity, reduce costs and maintain high quality standards. As welding technology continues to advance, MIG welding is likely to continue to play a crucial role in the evolution of manufacturing processes.

References

Source own