Table of Contents

- Operating principle of the internal floating roof tank

- Difference between internal and external floating roof tanks

- Types of internal floating roofs

- Why is aluminum the preferred material for IFRTs?

- Sealing systems and emission control

- API 650 Appendix H and regulatory requirements

- Mechanical integrity and operational reliability

- Technical innovations in aluminum floating roofs

- When should a tank be retrofitted with an internal floating roof?

- Conclusions

- References

- Frequently Asked Questions (FAQs)

The internal floating roof tank (IFRT) is one of the most effective solutions for reducing hydrocarbon emissions in the atmospheric storage of volatile products. Its operational function does not rely solely on the principle of flotation; it is also influenced by the interaction between structural design, material selection, sealing systems, and compliance with regulatory requirements established in API 650.

In the face of increasing regulatory pressure, the need to control evaporative losses, and the optimization of operations, the IFRT is a key asset for tank emission reduction, preservation of the stored product, and control of operational risks associated with storage.

Operating principle of the internal floating roof tank

An internal floating roof tank (IFRT) incorporates a floating deck installed beneath a fixed roof, reducing the vapor space above the liquid and, consequently, losses due to breathing and filling/emptying cycles. In addition, the fixed roof protects the system from sun and rain, stabilizing seal performance and limiting climate-driven emission variability.

From a physical standpoint, the IFRT acts as a mobile barrier that follows the product level, significantly reducing the evaporation of Volatile Organic Compounds (VOCs). Its performance is directly influenced by:

- Flatness and rigidity of the floating system.

- Continuity and design of primary and secondary seals.

- Electrochemical compatibility of materials.

- Installation quality and maintenance.

- Emissions from fittings and penetrations (gauging, drains, supports).

Difference between internal and external floating roof tanks

The difference between an internal floating roof tank (IFRT) and an external floating roof tank (EFRT) lies mainly in how the external environment affects sealing system stability and thermal balance, directly influencing emission control consistency.

In EFRTs, the deck is exposed to solar radiation, rain, and wind, which may induce movement, water accumulation, and accelerated wear of the rim seal, increasing fugitive emissions under adverse weather conditions.

In contrast, the IFRT operates protected by a fixed roof, reducing environmental aggressiveness and enabling more stable control of hydrocarbon emissions, which are mainly concentrated at fittings and in the annular space between the deck and the shell.

Types of internal floating roofs

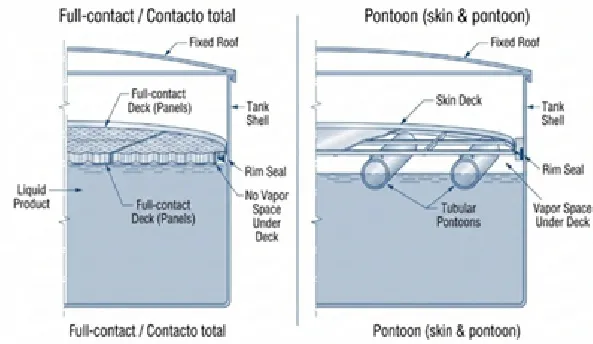

In an IFRT, internal floating roofs are classified according to their interaction with the stored product and the vapor volume beneath the deck, criteria directly related to emission control and compliance with API 650 Appendix H.

- Full-contact: The deck rests directly on the liquid surface, minimizing vapor volume beneath the roof and providing superior emission control.

- Pontoon (skin & pontoon): Incorporates flotation compartments (e.g., tubular/pontoon type), leaving a vapor volume beneath the deck; commonly used due to robustness, assembly tolerance, and structural behavior.

- Pan and hybrid designs: Used in specific applications, combining features of both systems depending on product volatility, tank diameter, and sealing strategy.

Aluminum floating ceilings dominate the IFRT market due to their strength-to-weight ratio and aluminum’s corrosion resistance; additionally, the selection must balance emissions, mechanical integrity, accessories, and operating conditions.

Why is aluminum the preferred material for IFRTs?

Aluminum is widely used in internal floating roof tanks for clearly defined technical reasons related to its structural, chemical, and operational behavior in hydrocarbon storage applications.

- High specific strength: Provides adequate structural capacity with low weight, reducing loads transferred to the tank shell.

- Natural formation of a protective oxide: Spontaneously develops a stable surface film that acts as a barrier against corrosion.

- Good performance in hydrocarbon atmospheres: Maintains chemical stability in environments containing petroleum product vapors.

- Ease of installation and modularity: Enables modular designs that simplify assembly and reduce intervention time.

Aluminum oxidation and its protective effect

Aluminum oxidation generates a continuous, adherent passive layer that protects the base material from degradation. This phenomenon explains its favorable corrosion performance, provided that design controls conditions that may break passivation (persistent moisture, deposits, galvanic couples).

Risks of galvanic corrosion

Galvanic corrosion may occur when aluminum comes into electrical contact with carbon steel in the presence of an electrolyte. To mitigate this risk, IFRT design should consider:

- Electrical isolation between dissimilar materials.

- Proper selection of fasteners and joining elements.

- Effective control of drains and condensate.

- Management of wetting at joints and retention points.

Sealing systems and emission control

Sealing systems are the most critical component for reducing VOCs in an internal floating roof tank, as they constitute the primary barrier between the product and the tank atmosphere. In practical terms, when an IFRT fails to meet emission targets, the root cause is usually seals, penetrations, and fittings rather than deck flotation.

Primary and secondary seals

- High radial adaptability, allowing continuous contact with the tank shell

- Multilayer designs aimed at reducing permeability and limiting evaporative losses

- Dynamic behavior capable of absorbing geometric variations such as ovality, construction tolerances, and floating deck movements

An inadequate, poorly installed, or degraded sealing system can negate the environmental benefit of the IFRT, even when the floating roof structure meets design and flotation requirements.

API 650 Appendix H and regulatory requirements

API 650, Appendix H, specifically addresses technical criteria associated with the design of internal floating roofs to ensure mechanical integrity and functionality. Key aspects include:

- Structural requirements for the floating roof, considering self-weight and operating loads

- Minimum flotation requirements; the roof must remain afloat even if two compartments are flooded or punctured, a critical safety condition

- Deflection/serviceability criteria to prevent loss of functionality or structural damage

- Compatibility and arrangement of sealing systems and penetrations

In summary, the standard does not merely “require flotation”; it also demands flotation margins (e.g., supporting at least twice the self-weight) and the ability to remain operational under compartment damage scenarios, while accounting for seal friction and filling loads.

Mechanical integrity and operational reliability

From an asset management perspective, the IFRT must be integrated into Risk-Based Inspection (RBI) programs, considering both structural and functional factors. Critical aspects include:

- Permanent deformation of the floating roof.

- Damage associated with overpressure or vacuum events.

- Localized corrosion attack, especially at joints and fittings.

- Failures in drainage or sealing systems.

- Condition and tightness of flotation compartments.

System reliability directly influences tank emission reduction, operational continuity, and control of risks associated with hydrocarbon storage.

Technical innovations in aluminum floating roofs

The evolution of aluminum floating roofs has focused on improving emission control, structural reliability, and ease of installation in atmospheric storage tanks. Recent advances emphasize modular architectures, flotation optimization, deflection control, and better integration of critical accessories (penetrations, drains, gauging), enabling improved compliance with API 650 requirements.

As an applied technical reference, the following video produced by INSPENET TV featuring HMT LLC shows aluminum floating roof solutions under real operating conditions, linking design, installation, and environmental performance.

HMT aluminum floating ceiling solutions

When should a tank be retrofitted with an internal floating roof?

Retrofitting an IFRT is a technically viable alternative when improving emission control without replacing the asset. It is recommended when:

- High evaporative losses are identified in fixed-roof tanks.

- Environmental improvements are required while maintaining existing infrastructure.

- Regulatory requirements related to emissions and vapor control are updated.

- The tank stores highly volatile products, where free vapor space represents an environmental and operational risk.

Retrofit evaluation should consider tank structural analysis, material compatibility (including galvanic corrosion), operating conditions, interference with internal columns versus self-supporting roofs, and the environmental benefit achieved relative to investment.

Conclusions

The internal floating roof tank is a technical and strategic solution for tank emission reduction, combining environmental efficiency, structural reliability, and regulatory compliance under API 650. The use of aluminum floating roofs, together with proper seal design and control of phenomena such as galvanic corrosion, maximizes long-term operability.

When properly integrated into a mechanical integrity strategy (RBI), the IFRT not only reduces hydrocarbon emissions but also stabilizes operations, preserves product, and strengthens storage risk management.

References

- Qian, X.; Yuan, M.; Huang, W.; Krause, U. Floating Roof Tanks. ScienceDirect.

Frequently Asked Questions (FAQs)

What are the different types of internal floating roofs?

The most common are full-contact and pontoon/skin & pontoon, which differ in vapor volume beneath the deck and sensitivity to fittings/penetrations. Selection depends on volatility, diameter, internal interferences, sealing strategy, and API 650 criteria.

How effective is an IFRT in reducing emissions?

In practice, an IFRT can achieve very high reductions in evaporative emissions compared to a fixed roof, as it minimizes vapor space and stabilizes sealing. Actual performance depends on seal condition, fittings, and operating/inspection practices.

Why is aluminum the preferred material for IFRTs?

Because it offers a high strength-to-weight ratio, improving structural response without overloading the tank, and forms a protective oxide film that enhances durability. Nevertheless, design must control retained moisture and galvanic couples.

Can galvanic corrosion affect aluminum floating roofs?

Yes. If aluminum–steel electrical contact exists in the presence of an electrolyte (condensation/water), galvanic corrosion may develop locally. Therefore, isolation, fastener selection, and drainage/condensate management are recommended as part of the design.

When should an IFRT be refurbished?

An internal floating roof tank should be refurbished when inspections identify loss of flotation, excessive deck deflection, seal degradation, increased emissions, corrosion at joints or fittings, or operational issues affecting roof movement. Refurbishment is also recommended when regulatory requirements change, emission targets are no longer met, or when extending the service life of the tank is more cost-effective than full replacement.