In the field of industrial infrastructure, storage tanks play an important role in the storage of various liquids, from water to petrochemicals. Ensuring the structural integrity of these tanks is necessary to prevent leaks, environmental contamination and possible dangers. One area prone to corrosion is the annular ring, a critical component that supports the tank and maintains its stability.

This article delves into the importance of inspecting the annular ring of in-service storage tanks for corrosion and how Pulsed Eddy Current (PEC) technology has emerged as a valuable tool in this regard.

Understanding the annulus

The annular ring, also known as the bottom ring or rim ring, is a structural component located at the bottom of storage tanks. This ring provides support for the tank, distributing its weight evenly and ensuring its stability. Due to their proximity to the tank base and exposure to environmental factors, annular rings are susceptible to corrosion over time. Corrosion in this ring can compromise the structural integrity of the entire tank, leading to leaks and potential environmental disasters.

Challenges in in-service tank inspection

Traditionally, inspecting storage tanks for corrosion requires taking the tank out of service, draining it, and performing a thorough visual inspection and other non-destructive testing, such as Magnetic Field Leakage (MFL), Ultrasonic Testing (UT). ), among others. However, this approach presents significant challenges, such as downtime, cost implications, and the logistical complexity of temporarily taking important industrial infrastructure equipment out of service. In-service inspection methods are necessary to address these challenges and ensure the continued operation of storage tanks.

Performing this evaluation from outside the tank requires access to the annular ring. Storage tanks can rest on various foundation materials, including soil, asphalt, and concrete. If the foundation material is soft, the floor of an atmospheric storage tank may sag, even if only slightly, creating uneven gaps between its base and the annular ring.

This exposes the edge of the tank floor to factors that generate corrosion and, therefore, loss of wall thickness, compromising the integrity of the tank . However, this access or having a soft surface under the floor allows access with special devices or probes to evaluate the state of the metal on the tank floor.

Inspection of the annular ring from the outside of a storage tank is not possible with ultrasonics (UT), as they require thorough removal of all corrosion products. Other in-service inspection methods, such as acoustic emission, only provide rough indications of wall loss and are difficult to analyze.

Pulsed Eddy Current Technology for the evaluation of annular rings

Pulsed Eddy Current (PEC) technology has emerged as a non-destructive testing method that enables the inspection of in-service storage tanks. PEC is based on the principles of electromagnetic induction, where a pulsating magnetic field induces eddy currents in the material being inspected. By analyzing the response of these eddy currents, inspectors can obtain information about the thickness of the material, its conductivity and possible corrosion.

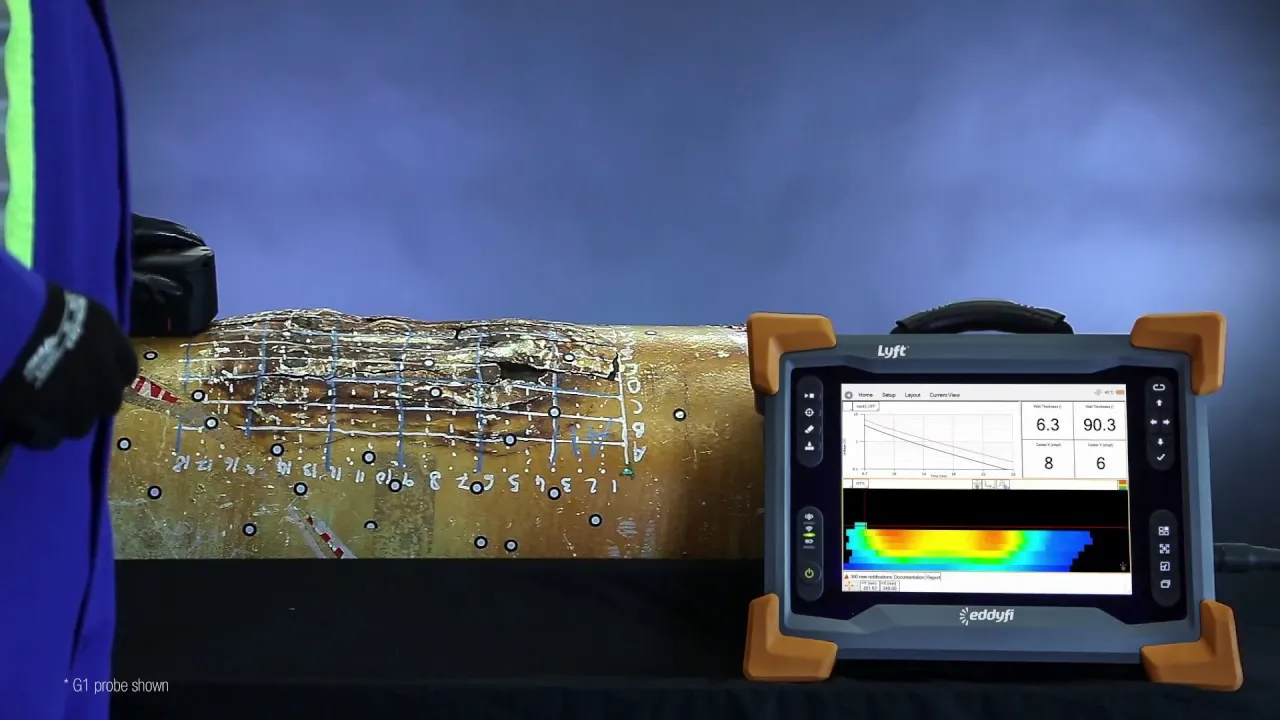

The Eddyfi Lyft PEC solution offers a great way to inspect annular rings of atmospheric storage tanks for wall loss without taking them out of service: Using Lyft equipment, special software for this application and a tank floor probe specifically designed for this inspection, which consists of a super-thin 4.8 mm (0.2 inch) titanium blade.

Through SmartPULSE™ technology, Lyft software features advanced automation and algorithms that eliminate operator-specific dependency. SmartPULSE automatically optimizes the parameters of the pulse emitter and receiver (gain, duration, time gates, filters, etc.). It also optimizes wall thickness (WT) measurements, ensuring the best performance and repeatability, while limiting the need for advanced PEC knowledge.

Video courtesy of Eddyfi Technologies .

Advantages of PEC for tank inspection

- Non-intrusive inspection: PEC allows inspection without the need to physically access the interior of the tank. This minimizes the impact on operations and eliminates the need for costly and lengthy tank shutdowns.

- Broad Surface Coverage: PEC technology can cover a large surface area quickly, making it efficient at inspecting the entire annular ring, identifying corrosion deterioration in its early stages before it progresses to a critical level.

- Depth Penetration: PEC can penetrate coatings and insulations, providing accurate readings even in situations where the annular ring surface is not directly accessible. This is particularly advantageous in cases where tanks have protective coatings or layers of insulation.

- Quantitative data: PEC generates quantitative data that can be analyzed to determine the severity and extent of annular ring corrosion; which allows informed decision making regarding maintenance and repairs.

- Real-time monitoring: PEC inspections can be performed in real time, providing immediate feedback to inspectors. This allows for on-the-fly decision making and facilitates quick action if corrosion is detected on the annular rings.

Conclusions

Inspecting the annular ring of in-service storage tanks for corrosion is an important aspect of ensuring the life and safety of these industrial assets. Pulsed Eddy Current technology has emerged as a transformative technique in this field, offering a non-destructive, efficient and accurate method for inspecting annular rings without the need to shut down tanks.

As industries continue to prioritize safety, environmental responsibility and operational efficiency, PEC is expected to become standard practice in the ongoing effort to safeguard storage tanks from corrosion-related issues.

References

- EDDYFI. Inspecting In-Service Storage Tank Annular Rings For Corrosion; Consulted on January 11, 2024; https://www.eddyfi.com/doc/AppnoteDownloads/Application-NoteInspecting-In-Service-Storage-Tank-Annular-Rings-for-Corrosion20180801.pdf