The history of metals shows how these elements have accompanied humans since their origins, marking technological and social milestones at each stage of civilization. Characterized by their shine, malleability, and conductivity, metals have been key in the transformation of humanity, from the Stone Age to today’s industrial and technological society.

The aim of this article is to explore the history of metals, from the origin of copper to the development of steel, highlighting their impact on the culture, economy, and technology of human societies. Through this journey, we seek to understand how metals have been drivers of progress and continue to be fundamental in modern life.

Metals: the foundation of human civilization

The term “metal,” derived from the Greek metallon, means a product extracted from a mine. Copper, silver, and gold were among the first metals to be worked in their natural state, driving the beginning of metallurgy. The ability to transform these materials allowed societies to manufacture tools, weapons, and ornaments, laying the foundations for cultural and economic progress.

Where did the history of metals begin?

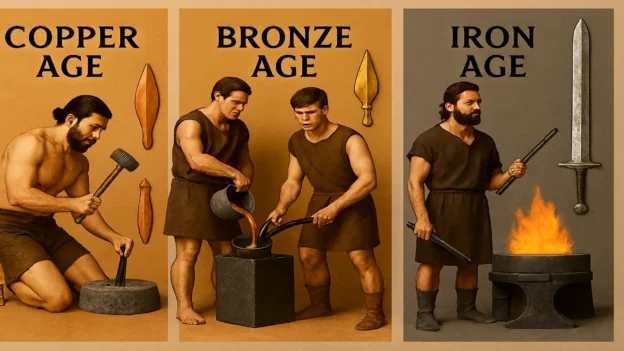

This period marked the transition from the use of stone tools to working with metals, transforming the lives of human communities. It is divided into three fundamental phases that shaped civilization: copper, bronze, and iron.

Copper Age: the first metal worked

Copper was the first metal known and used by humanity, around 5000 BC, in regions such as Mesopotamia and Egypt. Found in nature in its native state, it could be worked by cold hammering, which allowed for the manufacture of arrowheads, knives, needles, and ornamental objects.

Over time, the technique of smelting was discovered, which paved the way for the production of more sophisticated containers and tools. Although not very resistant, copper represented the formal beginning of metallurgy, as it taught societies to transform raw materials into useful tools for everyday life.

Bronze Age: the first historical alloy

The discovery of bronze, an alloy of copper and tin, marked a qualitative leap in the history of mankind. From 3000 BC, in regions such as Mesopotamia, Egypt, China and Europe, bronze became the material of choice for the manufacture of weapons, armor, agricultural tools, sculptures and household utensils.

Its superior strength and durability to copper allowed the development of fortified cities, more powerful armies and an international trade based on obtaining and transporting tin. This stage consolidated the first global technological revolution, as bronze changed the way societies organized and competed for resources.

Iron Age: the metallurgy that transformed civilizations

Iron began to be worked around 1200 BC, initially in Anatolia and the Near East, and soon spread to Europe, Africa and Asia. Its abundance in the earth’s crust made it a much more accessible resource than copper or tin.

Although it was more complex to smelt, the mastery of techniques such as blast furnaces and forging made it possible to obtain more resistant, durable and economical tools and weapons. Iron progressively replaced bronze and revolutionized key sectors such as agriculture (with more efficient plows), construction (with nails and reinforced structures) and warfare (with swords, spears and armor of greater destructive power).

The Iron Age was decisive because it changed the political and economic organization of societies, leading the way to the great empires of antiquity and establishing the basis for the modern metallurgy that would drive the Industrial Revolution centuries later.

How did metallurgical techniques evolve?

Metallurgy began in a rudimentary way with the cold hammering of native metals such as copper and gold, a technique that did not require furnaces or smelting. Over time, people discovered that applying heat to certain minerals made it possible to extract purer and more malleable metals. This gave rise to smelting, a process that consisted of heating the ore in clay ovens until the metal was separated from the rock, which made it possible to manufacture more resistant tools with more complex shapes.

During the Bronze Age, experimentation led to the creation of alloys, combinations of metals that improved the hardness, elasticity and durability of objects. This advance was fundamental, since bronze not only revolutionized the manufacture of weapons and tools, but also opened the way to international trade in metals such as tin, generating trade routes and strategic alliances between civilizations.

With the advent of iron, metallurgy became more sophisticated. Techniques such as forging, in which metal was heated red-hot and shaped by hammering, and later blast furnaces, which allowed higher temperatures to be reached to obtain purer and more malleable iron, were developed. These advances led to the production of metal plows that transformed agriculture, while iron weapons gave military superiority to many peoples.

In the Middle and Modern Ages, metals were also incorporated into art and culture. Casting techniques were applied in the creation of bells, musical instruments, sculptures and architectural elements such as grilles, stained glass windows with metal structures and reinforced Gothic cathedrals. The metallurgical evolution not only changed the economy and warfare, but also left a cultural and artistic legacy that still endures today.

This video describes how metallurgy developed an order related to the properties of metals available to humans. Increased human knowledge of these properties makes today’s information age possible and continues to shape our lives. Source: James Sword Engineering.

The evolution of metallurgy through the ages.

Why are metals still important today?

Today, metals are the backbone of industrial and technological society. Iron and its most important alloy, steel, form the invisible skeleton of our cities: skyscrapers, bridges, roads, railway systems and ships depend on them for their construction and durability. In addition, aluminum, because of its lightness and resistance to corrosion, is indispensable in the aeronautical and automotive industries and in food packaging.

The technological revolution of the 20th century increased the importance of metals. Copper, due to its high conductivity, is essential in electrical systems, wiring and electronic circuits. Lithium, cobalt and nickel have become strategic resources for the development of rechargeable batteries and clean energies, driving the transition to electric vehicles and renewable energies. In the same vein, titanium stands out in biomedical applications, such as prostheses and pacemakers, due to its biocompatibility and strength.

Beyond their technical utility, metals maintain a symbolic and economic value. Gold and silver remain mainstays of jewelry and financial investment, while metals such as platinum have applications in both jewelry and the automotive industry (catalysts). Even in the digital age, precious metals continue to underpin economies and international markets.

Metals remain irreplaceable because they combine tradition and modernity: they have sustained ancient civilizations and are now key to technological innovation, energy sustainability and the development of new ways of life in the contemporary era.

Contemporary applications of metals

Today, metals are fundamental to infrastructure, industry and technology, forming the basis of modern life. Iron and steel form the skeleton of skyscrapers, bridges, roads and urban structures, providing strength, durability and safety. Aluminum is essential in aeronautics, transportation and packaging, thanks to its lightness and resistance to corrosion.

In the technological field, copper is essential for its high electrical and thermal conductivity, present in cables, electric motors and energy systems. Other strategic metals, such as lithium, cobalt and nickel, are used in the manufacture of rechargeable batteries, driving the transition to electric vehicles and renewable energies, reinforcing the importance of metals in sustainability and energy innovation.

In medicine and biotechnology, titanium and its alloys are used for prostheses, pacemakers and implants because of their biocompatibility and corrosion resistance, showing how metals combine functionality and safety in modern applications. In addition, metals hold economic and symbolic value. Gold, silver and platinum are fundamental in jewelry, currency and store of value. Even in the electronics and digital industry, precious metals are indispensable in circuits, chips and communication devices.

In short, metals remain irreplaceable because they integrate tradition, technology and economic development, sustaining infrastructure, innovation and everyday life in the 21st century.

Conclusion

The history of metals reflects the ability of humans to transform natural resources into tools, weapons, and cultural objects, driving social, economic, and technological development from early cold hammering to modern blast furnaces and alloys. These materials have been a constant engine of innovation, sustaining contemporary society and highlighting their relevance in construction, technology, industry and culture.

References

- Gordon, R. B., & Killick, D. (1993). Adaptation of technology to culture and environment: Early metallurgy in the African savanna. Technology and Culture, 34(1), 1–24.

- Tylecote, R. F. (1992). A history of metallurgy. Institute of Materials.

- Wertime, T. A. (1973). The beginnings of metallurgy: A new look. Science, 182(4115), 875–887.

Frequently Asked Questions (FAQs)

What was the first metal used by mankind?

Copper, worked by cold hammering since the end of the Neolithic period.

How important was the alloying of bronze?

Bronze made it possible to manufacture weapons and resistant tools, revolutionizing technology and society.

Why did iron replace bronze?

Because of its abundance and durability, facilitating great economic and military advances.

How did metals influence industrialization?

Steel was key in machinery, construction and transportation, accelerating modern development.

Are metals still important today?

Yes, in construction, energy, transportation, electronics, jewelry and coins.