Author: ing. Gustavo Romero, LATAM Director, PENSPEN. April 25, 2022.

“Tourism in Corrosion, a trip to learn about the beauty and importance of the

corrosion in iconic structures”

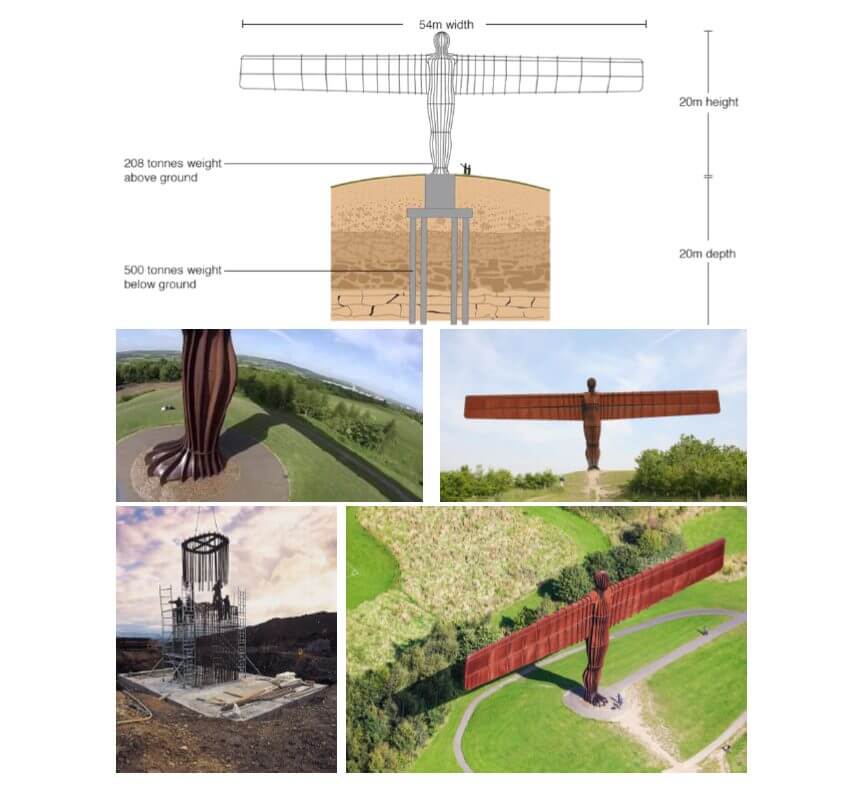

This time we head to North East England (UK) specifically to Gateshead, County of Tyne and Wear whose capital is Newcastle, to talk about a relatively new iconic structure known as The Angel of the North. If you go along the motorway that connects London with Scotland (Durham Rd) you can see it with its wings outstretched like a watcher in the Northumbrian countryside. It has a height of 20 meters and its wings measure 54 meters from end to end. It is located about 15 km from the North Sea coast (Figure 1).

What makes this monument special, apart from its impressive dimensions and construction process, from the point of view of a corrosionist, is the material used. In this case, the selected material was weatherproof steel whose chemical composition makes its oxidation, once atmospheric corrosion begins, have particular protection characteristics that keep the mechanical properties of the structure practically intact for a long time.

This type of steel is known as COR-TEN, which was patented by the United States Steel Corporation in 1933 and whose name is due to its corrosion resistance and mechanical strength properties. Whenever I am interested in a structure, I try to investigate its reason for being, that is, why an angel? and not another symbol, why with outstretched wings? and not in another position and in this case, I will use the words of the same sculptor who literally explains that we have never seen a real angel and we have to continue imagining them.

This angel has three functions: firstly, a historical one to remember that under this site coal miners worked in the dark for two hundred years, secondly, the future, expressing the transition from the industrial age to the information age. and lastly, to be a beacon of hope.

Initially it was rejected by some inhabitants of the area, especially because of the investment involved in designing and building it, however, today the Angel of the North is considered a symbol, an icon of this part of England, and thousands of people visit it while it pays a quiet tribute to the industrial heritage of the northwest of the country.

I have visited the city of Newcastle on several occasions, however, I have not had the opportunity to see this impressive monument, so I will be keeping an eye on my next visit to demand that my co-workers organize a visit so that I can witness as my own eyes the beauty of this corroded structure. I dedicate this post to my colleagues at the Penspen Newcastle office.

About Material

The material selected for the construction of this structure was COR-TEN steel, also known as patinable steel or low alloy steel for weathering, whose composition requires a carbon content of less than 0.2% by weight, Cu (0.2-0.55%), Cr (0.4-1.25%), Ni (0.65%), P (0.03-0.15%) and other elements that add up to a total content between 1% and 5% by weight, which is equivalent to a higher proportion than that normally found in plain or mild carbon steels. They constitute a class of structural steel that develops an adherent layer of protective oxides, called patina, during exposure to the atmosphere in low-aggressive environments.

COR-TEN steel was patented by the United States Steel Corporation in 1933 which released it as a low alloy steel with 0.2-0.5% copper, 0.5-1.5% chromium and 0.1 – 0.2% phosphorus. The composition over the years has undergone some changes, such as the introduction of 0.4% nickel, the reduction of phosphorus to 0.04%, as well as the addition of small amounts of other elements, capable of improving its mechanical resistance.

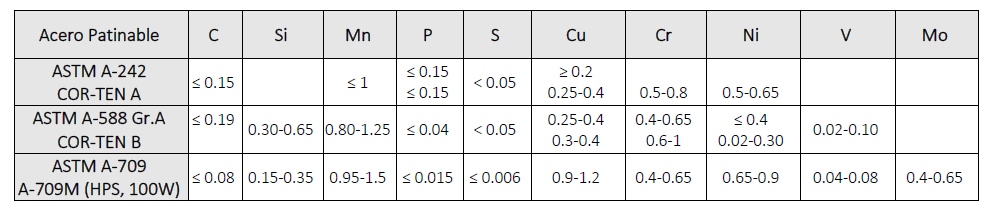

Currently, COR-TEN steels with a yield strength of up to 580 MPa can be obtained. Nowadays, it can be classified based on different American, European, Japanese and Chinese standards. The American Society for Testing Materials (ASTM) has standardized different compositions for these patinable steels. In Table 1, the chemical compositions of three commonly used patinable steels are shown.

Table 1. Chemical compositions of patinable steels.

About Construction

The Angel of the North was built by Hartlepool Steel Fabrications and installed in 1998. Its construction took four (04) years and had an approximate cost of 800 KGBP. It consists of three main parts, the body weighing 100 tons and two wings weighing 50 tons each supported by foundations that required pouring one hundred and fifty tons of concrete to form piles to root the sculpture into the solid rock 20 meters below. Figure 2 shows a schematic representation of the construction of the Angel.

assembly of the statue

Each part contains a combination of up to five elements, (Figure 3).

• Ribs: The external skeleton cut from 50mm thick steel allows the structure that holds the angel together to be integral to its appearance.

•Skin: 6 mm sheet steel bent and welded to the ribs that make up the shape of the body.

• Sacrificial ribs – lie under the skin plates and help give them way.

• Diaphragms, which look like ribs on the surface, are actually horizontal plates thickness of 50 mm that cross the body, up to six meters by three meters and weigh almost five tons. There are five of these, the most important being the chest, which lines with the horizontal wing diaphragms to provide a solid anchor point.

• Core: the invisible skeleton that runs from the feet to the chest to provide support additional. This hollow steel tube, a series of cylinders and cones, reflects the shape of the body. It is a 30mm thick steel plate up to the knees and 15mm thick above. The Ribs on the bottom of the body are welded directly to the core.

This revolutionary approach to fabrication was devised by Hartlepool Steel Fabrications, who won the contract to build the Angel of the North. They worked closely with consulting engineers Ove Arup & Partners and the Gateshead Council to bring the Angel’s design to life. The original cast bodies of the Angel by the sculptor, Antony Gormley OBE, were scanned by the Newcastle University Department of Geomatics and the precise coordinates plotted to create an electronic 3D Virtual Reality Angel.

Grafton Software converted this data into a three-dimensional CAD model so that the computerized profiling machines used by Teesside Profilers could cut the main body into ribs following the exact curves of the artist’s original castings. The ribs were then delivered to Hartlepool Steel for construction. The wings of this angel are not flat, but have an angle of 3.5 degrees through which the artist wanted to convey the feeling of an embrace.

corrosion mechanism

When exposed to different environments, the corrosion resistance characteristics of weathering steel are affected in various ways. The corrosion rate increases when the relative humidity exceeds approximately 70%. A high percentage of relative humidity affects the wetting time, which is the time a metal remains wet enough to corrode at an appreciable rate.

To achieve the most desired protective ability of the oxide layer, wet and dry cycles of nearly equal duration should allow the patina to form and provide satisfactory corrosion resistance. Once the COR-TEN steel structure is exposed to the atmosphere and to the wetting and drying cycles, the electrochemical corrosion process begins, which involves the oxidation of iron and other elements such as copper, nickel and phosphorus mainly, which generates a surface film of oxides, dense, stable, adherent and impermeable to water and water vapour.

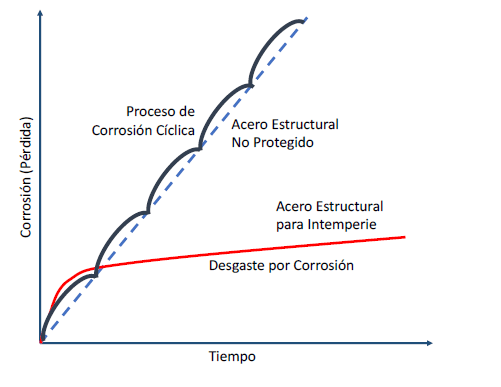

This film is comparable to the patina seen on cast iron when exposed to the atmosphere and will significantly reduce the rate of corrosion. This is what prevents the oxidation of the steel from continuing towards the interior of the piece. This surface film protects the core of the COR-TEN from atmospheric corrosion; therefore, it is not necessary to apply any other type of protection to the steel. Figure 3 shows a schematic representation of the difference in corrosion rate between COR-TEN steel and normal steel when exposed to an ideal atmosphere.

Protective layer of corrosion products

There are many works that study the protection of the oxide layer formed on weather resistant steel exposed to the atmosphere. The main oxidation phases are different oxy-hydroxides such as α FeOOH (goethite), β-FeOOH (akaganeite) and γ-FeOOH (lepidocrocite), some types of iron oxides such as magnetite Fe3O4 are contained in the oxide layer depending on the environmental condition.

Between them, α-FeOOH forms a dense and uniform layer of nanoparticles, which are tightly bound to the underlying steel substrate. The ability to protect against corrosion is mainly attributed to this dense α phase whose formation is stimulated by the dry-wet-dry cycle.

Furthermore, improved corrosion resistance is achieved by adding alloying elements in which copper (Cu) has the most pronounced beneficial effect. Cu can retard the anodic dissolution of iron or lower the electronic conductivity of the oxide layer, so that the flow rate of electrons reaching the sites for cathodic reaction decreases. As with copper, nickel (Ni) can form small amounts of relatively protective hydroxy sulfates.

Like copper hydroxyl sulfates, they can improve the barrier effect by clogging the pores of the corrosion product layer. Chromium (Cr) results in the substitution of iron (Fe) for Cr in the α-phase, so that a densely packed nanometer-sized layer of α-(Fe1−xCrx)OOH is formed and contributes mainly in the long term. In the initial stage of formation, Cr, P and Cu have been observed in the CP layer closest to the substrate.

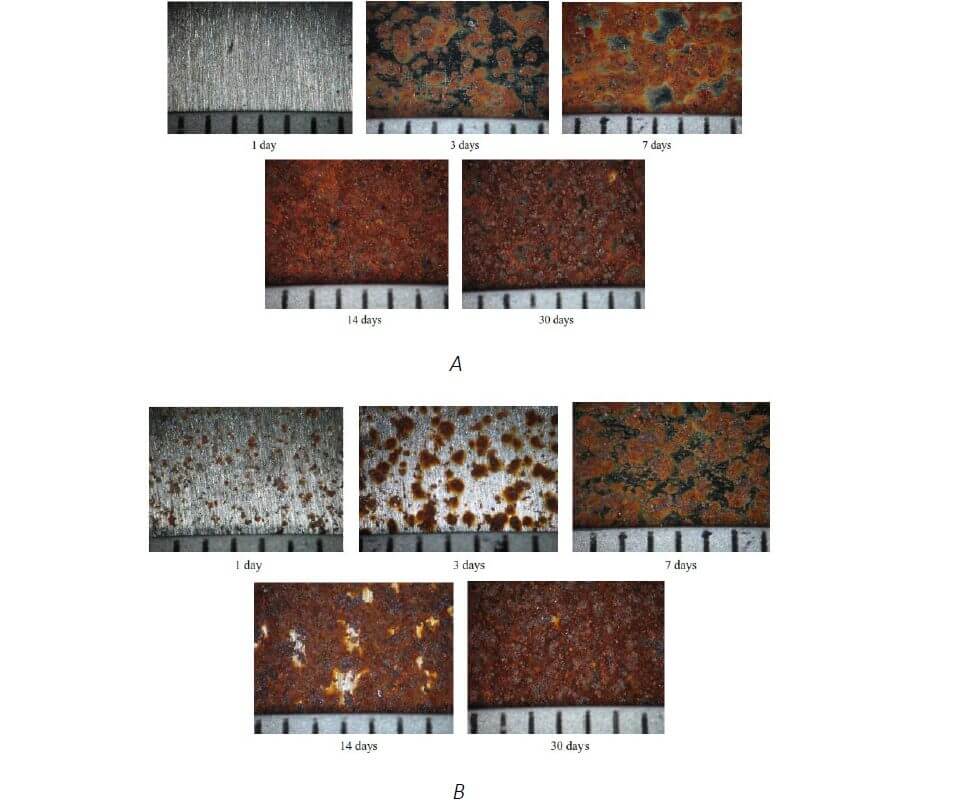

The formation process of this protective layer of corrosion products responds to a gradual process that varies from environment to environment and that begins as a localized corrosion process that later spreads throughout the material. In a study carried out to evaluate the characteristics of the corrosion product layer formed on weather resistant steel exposed to the tropical climate of Vietnam, the following images were obtained for different exposure times and two types of climatic conditions, as shown in the following Figure 4.

(B) Climate with higher concentration of chlorides (40 mg/m2 d)

Figure 4. Corrosion process in outdoor steel samples exposed to two types of environments.

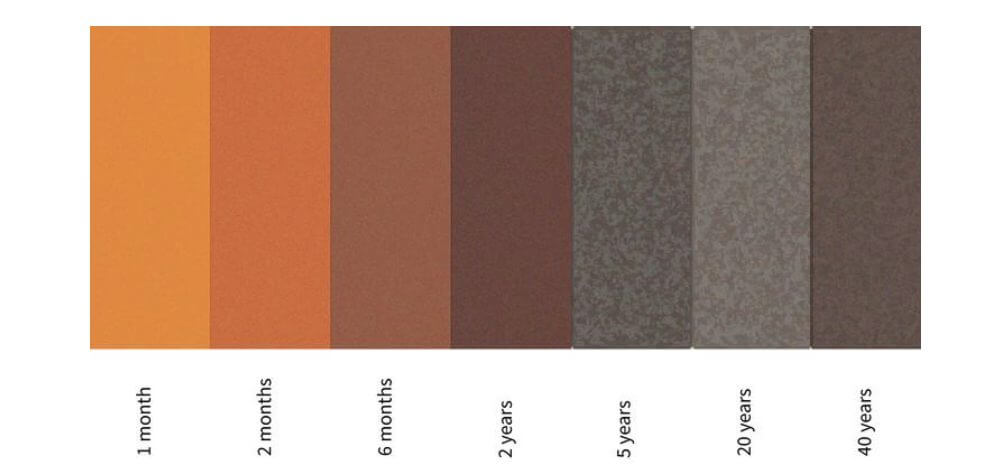

color changes

The atmospheric corrosion process of this material shows a yellowish appearance in the initial stage of use, and the color gradually changes to brown. Then, while in its surrounding environment, the color changes to a blackish brown in a year or two. Then the color changes very little once again, but only to a dark brown. Figure 5 shows the color change sequence expected in COR-TEN steel exposed to the atmosphere.

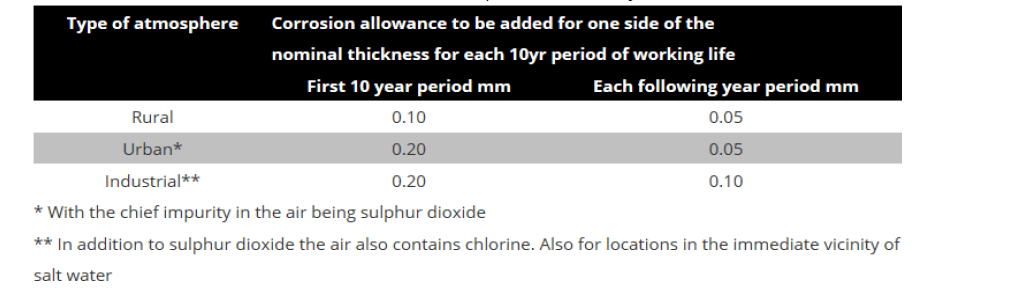

Table 2 shows the average corrosion rate results for COR-TEN steel in different atmospheric environments: rural, urban and industrial, and it can be seen that after 10 years the corrosion rate reaches very low values.

Table 2. Corrosion rate of patinable steels in different environments.

Some advantages

• Periodic cleaning and inspection should be the only maintenance required when uses weathered steel. Periodic cleaning consists of rinsing the Rusty surfaces with water to remove any natural residue or contaminants. Yes applied correctly, heavy rains can provide regular cleaning to the weathered steel members.

• Long-term cost savings are achieved by the durability of the material, which can be Look at the various structures and buildings built almost 50 years ago. Around the world, the DOT and transportation structures use the material because of its durability and cost savings to long term.

Utilizing the living and protective nature of this material also eliminates high costs associated with painting and lifetime costs associated with maintenance of painting on site. Where access for future maintenance is hazardous or difficult, or where it is necessary to minimize traffic disruption, COR-TEN steel It is an ideal lining material.

• The reduction of environmental impacts associated with emissions of organic compounds

VOCs from paint coatings and the cleaning functions required with the

paint, positions weather-resistant steel as a construction product

sustainable.

Final comments

• It is important to avoid puddles of water, since the protective film will not form if the surface is constantly wet. If water is allowed to accumulate in crevices will experience higher corrosion rates, steps should be taken to drainage or during design to evaluate options that mitigate this effect. The old Omni Coliseum, built in 1972 in Atlanta, Georgia, it never stopped rusting and eventually large holes appeared in the structure.

This was a major factor in the decision to demolish it just 25 years after it was built. The average relative humidity in the area where the Ángel del Norte is installed is normally in the order of 70%, which can affect the useful life of this structure since it will favor the presence of a continuous layer of water.

• Exposure to chloride ions in marine or coastal environments can prevent steel from is adequately protected and cause unacceptable corrosion rates. Some Experts recommend not installing this type of steel at a distance of less than 1 mile from the ocean shore or in areas where it may be exposed to continuous salt spray. corrosion suffered by the Aloha Stadium in Hawaii, built in 1975 with weathering steel, is a good example of this problem.

• Environments with high concentrations of corrosive chemicals or

industrial pollutants such as sulfur dioxide (SO2).

• Another limitation of the use of weather resistant steels is their appearance. Patina is visually similar to brown rust and can stain adjacent surfaces, which can be problematic when aesthetics are a consideration and makes visual inspection somewhat more difficult. US Steel Tower in Pittsburgh, Pennsylvania was built by US Steel in part to showcase COR-TEN steel.

The initial erosion of the material resulted in discoloration of the surrounding city’s sidewalks, as well as other nearby buildings. Stains can be mitigated by removing patterns that drain loose oxide products onto adjacent surfaces or by pre-aging the metal prior to installation.

• In general, it is recommended to avoid forming seams or overlaps where water can accumulate,

since its continuous presence would prevent the development of the protective film and

could become a source of corrosion.

References consulted

• Characteristics of Corrosion Product Layer Formed on Weathering Steel Exposed to the Tropical

Climate of Vietnam. Le Thi Hong Lien, Hoang Lam Hong. Materials Sciences and Applications,

2013, 4, 6-16

• Weathering Steels: From Empirical Development to Scientific Design. to Review. M. Morcillo,

I. Díaz, B. Chico, H. Cano, D. de la Fuente. National Center for Metallurgical Research

(CENIM-CSIC), Avda. Gregorio del Amo, 8, 28040 Madrid, Spain.

• Patinable steels (Cu, Cr, Ni): resistance to atmospheric corrosion and weldability. Heidis

Patricia Cano Picture. Complutense University of Madrid. faculty of

Chemical Sciences. Department of Materials Science of Metallurgical Engineering. 2014.

• The history of the Angel of the North.

Gateshead Council

https://www.gateshead.gov.uk/article/5303/The-history-of-the-Angel-of-the-North

About the Author

Gustavo Romero. A chemical engineer with a master’s degree in corrosion, he has served as a corrosion specialist, facility integrity and risk leader, project manager, and for the past 12 years has served as Director for Latin America for Penspen.