Table of Contents

- What are floating roof seals for AST tanks?

- Operational function and structural behavior

- Regulatory requirements

- Operational requirements and consequences of failure

- Types of seals for floating roofs on AST tanks

- Innovative materials for floating roof seals

- Operational risks and frequent failures in tank seals

- Routine inspection checklist according to API 653 (EFR / IFR)

- Advanced floating roof sealing technologies

- Conclusions

- References

- Frequently Asked Questions (FAQs)

The hydrocarbon storage industry faces the constant challenge of minimizing evaporation losses, ensuring operational safety, and complying with increasingly stringent sustainability regulations. In this regard, floating roof seals are the critical technology that closes the gap between the mobile roof and the tank wall, preventing hazardous vapors from escaping into the atmosphere.

Selecting the right sealing system is not just a regulatory requirement: it is a strategic decision for profitability and environmental protection. This article presents an advanced overview of the latest types, materials, configurations, risks, and technologies on the market for floating roof tank seals.

What are floating roof seals for AST tanks?

Floating roof tank seals are systems designed to close the annular space (rim seal) between the floating roof and the tank shell. This space, although small, is the most critical point for vapor formation and escape, as it is where most fugitive VOCs emissions are concentrated in tanks storing gasoline, naphtha, light crude oil, ethanol, and other highly volatile products.

Operational function and structural behavior

In these containment systems, perimeter seals also perform a mechanical function: they stabilize the movement of the floating roof and reduce unwanted vertical displacement. Full-scale experimental tests have shown that a well-designed seal can significantly increase liquid sloshing damping and suppress roof oscillations in a few cycles, providing structural stability.

When the floating roof, whether internal (IFR) or external (EFR), moves vertically with the product level, the seal must maintain continuous, uniform, and airtight contact with the tank wall. If this barrier does not function properly, three immediate risks arise:

- Accumulation of flammable vapors above the roof, promoting explosive mixtures.

- Increased economic losses due to evaporation of the stored product.

- Environmental non-compliance, especially in countries with strict emissions regulations.

To control these risks, perimeter seals form barriers that limit vapor emissions and maintain the tank’s airtightness, compensating for tank ovalization, differential settlement, and thermal changes that cause the steel to expand or contract. This adaptability allows for containment to be maintained even in tanks with imperfect geometries or those subject to varying operating conditions.

Regulatory requirements

From a regulatory standpoint, high-performance seals are not an option: they are a mandatory technical requirement. Standards such as EPA 40 CFR Part 60 Subpart Kb, API 650, API 2000, and API 653 require operators to demonstrate effective emission control and maintain the mechanical integrity of the system. In particular, API 2000 defines the criteria for breathing and vapor space management, parameters directly linked to the efficiency of the perimeter seal.

Operational requirements and consequences of failure

In operational terms, seals must function consistently, stably, and smoothly throughout the operating cycle, withstanding UV radiation, thermal loads, rim space variations, and severe environmental conditions. When a seal degrades or fails, the consequences are direct:

- Increased fugitive emissions

- Increased product loss through evaporation

- Unscheduled repairs

- Increased environmental risk

For these reasons, perimeter seals are one of the most inspected components in floating roof tank maintenance programs.

Types of seals for floating roofs on AST tanks

The sealing systems used in AST tanks are one of the most critical elements for controlling fugitive emissions and preventing flammable atmospheres. From design engineering to field operation, the selection, configuration, and performance of a seal directly impact containment efficiency, floating roof service life, and regulatory compliance.

In this context, the industry distinguishes two key components: primary seals, responsible for closing the main annular space, and secondary seals, which act as aerodynamic and environmental reinforcement to ensure high-performance sealing throughout the operating cycle.

Primary seal: the first containment barrier

The primary seal is in direct contact with the vapor, and in certain configurations with the product, and defines the fundamental efficiency of the vapor control system. Its function is to minimize the presence of flammable gas in the rim space and maintain tightness during volumetric and thermal changes in the tank. In industrial practice, three technological families predominate, each optimized for specific operating conditions.

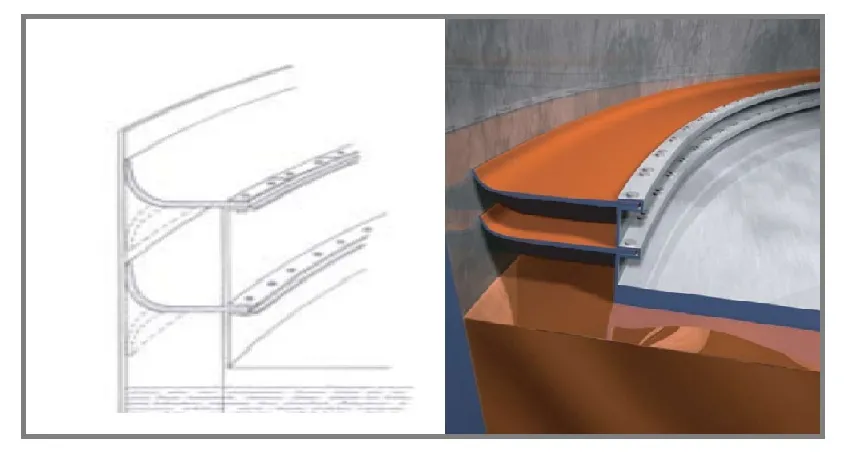

Mechanical shoe seal (MSS)

The mechanical shoe seal is the reference system in tanks that store highly volatile products or in facilities subject to strict environmental regulations. The design incorporates metal shoes, made of stainless steel or galvanized steel, which maintain continuous contact with the shell by means of pantograph mechanisms or calibrated springs. The connection between the shoe and the floating roof is made by means of a vapor barrier fabric, designed to withstand severe thermal cycles.

The MSS stands out for its ability to compensate for ovalization, thermal variations, differential settlements, and elevated roof movements. Its resistance to chemical and structural attack makes it the technical standard for large-diameter EFR tanks and for operations seeking to maximize emission reduction without compromising safety.

Liquid-Mounted Seals (LM)

In LM seals, the vapor barrier is formed directly on the surface of the product using flexible capsules or tubes filled with liquid or foam. This configuration virtually eliminates the vapor space under the seal.

However, their performance is closely linked to the chemical compatibility between the polymers in the system and the stored product; aromatics, oxygenants, and high temperatures can accelerate material degradation. For this reason, they are mainly used in internal floating roofs (IFR), where they are not exposed to UV radiation or rain.

Vapor-Mounted Seals (VM)

VM seals use compressed foam rings located above the vapor phase. Although they are inexpensive and quick to install, they maintain an internal vapor volume susceptible to the formation of flammable mixtures, making them less recommended in tanks that handle highly volatile products or in terminals subject to frequent environmental inspections. Their use is usually justified in applications where regulatory requirements are moderate and operational risk is controlled.

Secondary seal: reinforcement for emission control and system integrity

The secondary seal is installed over the primary seal and acts as a reinforcement layer that optimizes vapor containment and protects the system from external environmental factors, capturing residual vapors and preventing rain, dust, UV radiation, or abrasive particles from prematurely degrading the primary barrier.

Wiper seals

Wiper seals are made of high-strength elastomers that maintain flexible and continuous contact with the tank wall. Their design compensates for microdeformations in the hull and variations in rim space, offering stable aerodynamic performance and reduced maintenance. They are widely used in IFR and EFR due to their low profile and versatility.

Compression plate seals

These systems use metal or hybrid components that exert firm pressure on the shell, ensuring uniform contact even in the event of significant thermal expansion. When combined with an MSS primary seal, they can achieve emission reduction levels of over 98%, complying with the limits established by EPA 40 CFR Part 60 Subpart Kb and other international regulations. Their robustness makes them the optimal choice for terminals seeking sustained environmental performance and maximum reliability.

Together, the primary and secondary seals form a comprehensive system capable of adapting to the most demanding operating conditions, extending the life of the floating roof, and ensuring that the tank operates under the industry’s most rigorous safety and emissions standards.

Innovative materials for floating roof seals

The evolution of sealing systems in storage tanks has been driven by the need to reduce fugitive emissions, improve chemical resistance, and increase operational reliability.

Modern materials must withstand reactive hydrocarbons, UV radiation, moisture, abrasion, electrostatic charges, and severe thermal cycles. The correct material selection not only determines the performance of the seal, but also maintains the service life of the floating roof and the effectiveness of vapor control. The most relevant materials used in primary seals, secondary seals, and vapor barriers are described below.

PTFE (Teflon): superior chemical performance

PTFE is one of the most widely used materials in high-performance seals due to its resistance to aromatics, corrosive compounds, and highly aggressive chemical mixtures. Its low friction allows the seal to maintain uniform contact with the tank wall even during prolonged vertical movements, reducing wear and preventing loss of tightness. It has these key advantages:

- Outstanding resistance to aromatic hydrocarbons, ethanol, MTBE, and heavy solvents.

- Thermal stability in extreme ranges, ideal for severe climates.

- Low surface friction, reducing mechanical stress on the system.

This material is particularly recommended for tanks subject to rigorous environmental audits, where seal integrity is critical for regulatory compliance.

Engineered elastomers

Elastomers such as NBR, EPDM, and FKM are widely used in wiper seals, flexible membranes, and vapor barriers due to their balance of flexibility, mechanical strength, and chemical compatibility.

- NBR (Nitrile): Ideal for conventional hydrocarbons and fuels with low aromatic content.

- EPDM: Excellent performance against weathering, UV rays, and ozone; widely used in exposed EFRs.

- FKM (Viton): Superior chemical resistance for severe service and high-octane or aromatic products.

Its functionality allows for the design of hybrid seals and systems capable of compensating for local deformations without loss of tightness, a factor required in tanks with deformations or differential settlement.

Multilayer compounds: structural durability with flexibility

Multilayer systems combine aluminum, stainless steel, reinforced technical fabrics, and advanced polymers, creating a structure capable of withstanding extreme operating conditions without compromising the flexibility of the seal. Their outstanding features are:

- Excellent mechanical resistance to constant friction.

- Antistatic behavior to prevent charge accumulation.

- Long service life compared to single-component membranes.

These composites are used in both primary and secondary seals, especially in equipment that handles volatile products and requires long operating cycles.

One of the recent innovations in seal materials is Armor Fabric™, developed by Mesa ETP to improve the durability, chemical resistance, and mechanical performance of vapor barriers and liquid-mounted systems.

Learn more about innovative materials for floating roof seals in the following video.

ATEX and fire-retardant materials

In tanks located in classified areas, the selection of materials must control the generation of electrostatic charges and reduce the spread of fire in hazardous scenarios. For this reason, many manufacturers incorporate:

- Antistatic polymers, designed to maintain electrical continuity in the seal.

- Fire-retardant materials, compatible with NFPA and ATEX requirements.

- Metal components with special coatings that minimize sparks from impact or friction.

These materials provide an additional layer of safety, especially in EFR tanks where interaction with dust, water, wind, and radiation can increase the risk of accumulated electrostatic charges.

In addition to these materials, specialized manufacturers are developing technologies that increase the tightness and reliability of floating roof seals. Among them is Mesa ETP, whose WG Seal system maintains constant pressure even in tanks with ovalization, achieving a more stable seal. Its ClipLock™ technology eliminates perforations in the vapor barrier, reducing leak points and speeding up installation. For secondary seals, MesaWedge™ offers uniform contact and exceptional UV and abrasion resistance.

In the following audiovisual presentation, Mesa ETP presents its perimeter sealing systems for storage tanks, highlighting the engineering of WG Seals and other solutions designed to improve tightness, reduce emissions, and optimize operational performance in floating roofs.

WG seals primary & secondary seal system from Mesa ETP.

Operational risks and frequent failures in tank seals

Floating roof seals can fail due to chemical degradation, hull deformation, or loss of mechanical continuity. Among the most common risks are:

- Accumulation of flammable gases in the annular space.

- Degradation of elastomers due to aromatics, temperature, or UV radiation.

- Gaps outside API tolerance, reducing tightness.

- Roof misalignment, causing friction and irregular wear.

- Corrosion in roof, pantographs, or primary seal fittings.

- Water ingress, affecting buoyancy and structural stability.

A periodic inspection regulated by API 653 allows for the detection of leaks, deformations, and failures in the vapor barrier before compromising operation or safety.

In addition to mechanical and emission risks, floating roof tanks are also vulnerable to atmospheric discharges. API RP 545 establishes bonding and grounding guidelines to reduce the risk of electric arcs in the rim seal, reinforcing the need to maintain electrical integrity and continuity of the sealing system.

Routine inspection checklist according to API 653 (EFR / IFR)

Routine inspection in accordance with API 653 must verify:

- Rim space clearance within the limits defined in API 653.

- Continuity of primary and secondary seal contact.

- Condition of membranes, fabrics, and elastomers, free of tears, wear, or reinforcement exposure.

- Condition of shoes, pantographs, and support mechanisms, free of corrosion, deformation, or jamming.

- Absence of liquids or residues in the rim space that could compromise seal movement or roof buoyancy.

- Electrical continuity in antistatic systems according to the manufacturer and API 653.

Advanced floating roof sealing technologies

Modern floating roof seal engineering is advancing toward precise, safe, and sustainable systems, driven by greater environmental and operational demands. The most relevant trends include:

- Zero-emission systems, aimed at eliminating virtually all leakage in the rim space.

- Anti-corrosive composite materials, capable of withstanding aggressive hydrocarbons, UV, and severe thermal cycles.

- Quick-install modular seals, which reduce downtime and facilitate maintenance.

- Self-adjusting components, designed to compensate for hull deformation and variable clearances.

- Antistatic and fire-retardant materials, required in ATEX or NFPA classified areas.

- CAD–CAM design and precision manufacturing, optimizing the geometry and performance of mechanical shoes.

Conclusions

The efficiency of a floating roof tank depends largely on the sealing system’s ability to maintain vapor containment under various operating conditions. Choosing the right configurations, primary seal, secondary seal, and vapor barrier reduces emissions, maintains mechanical stability, and extends equipment life.

Recent developments in materials, design, and manufacturing for floating roof seals offer more stable sealing and consistent performance in aggressive products and demanding environments. Advanced seals ensure that the asset remains within international standards for integrity, safety, and environmental protection.

References

- Doustvandi, A; Roudsari, M; Niazi, B; (2023). Experimental Investigation on the Effect of Seal Presence on the Behavior of Double-Deck Floating Roofs in Cylindrical Steel Storage Tanks. Structural Durability & Health Monitoring (SDHM), 2023, Vol 17, Issue 1, p55. DOI:10.32604/sdhm.2022.017458.

- Ye, H. et al. (2024). Development and Status of Sealing System from Internal Floating Roof Tank. In: S. Shmaliy, Y. (eds) 8th International Conference on Computing, Control and Industrial Engineering (CCIE2024). CCIE 2024. Lecture Notes in Electrical Engineering, vol 1253. Springer, Singapore. https://doi.org/10.1007/978-981-97-6937-7_66.

Frequently Asked Questions (FAQs)

What is a floating roof tank?

It is a tank whose roof rises and falls with the product level to reduce headspace and minimize VOC emissions.

What is the function of the seal in a floating roof?

To close the annular space, prevent vapor leaks, prevent water or dust from entering, and maintain operational safety.

What are the most common types of seals?

Mechanical shoe seal (MSS), liquid-mounted seals, vapor-mounted seals, wiper seals, and compression seals.

What are the parts of a seal?

Metal shoe, pantographs or springs, vapor barrier fabric, elastomeric components, clamps, fasteners, and antistatic elements.

What is the difference between a primary and secondary seal?

The primary seal is the main containment barrier; the secondary seal captures residual vapors and protects the system from weathering.