Table of Contents

- Technological foundation of the flexicoking process

- Comprehensive description of process sections

- Flexigas conditioning and energy balance

- Fractionation and product recovery

- Critical operational variables in deep conversion

- Structural advantages over traditional schemes

- Environmental and strategic benefits of Flexicoking

- Importance in heavy crude refining

- Conclusions

- References

The transformation of heavy residues constitutes one of the greatest technical and economic challenges in contemporary refining. The increase in the production and processing of heavy and extra-heavy crudes has raised the proportion of vacuum bottoms and streams with high Conradson carbon, metals, and sulfur content. In this context, deep residue conversion is not merely a technological option but a structural necessity to maximize the recovery of useful fractions and minimize the generation of low-value solid byproducts.

The Flexicoking process represents an integrated deep conversion solution that combines fluidized-bed thermal coking with partial gasification of the coke produced, significantly increasing the degree of carbon conversion contained in the residue. Unlike conventional schemes, this technology allows most of the residual carbon to be transformed into liquid products and internally usable fuel gas, optimizing the energy balance and reducing the accumulation of solid coke.

Technological foundation of the flexicoking process

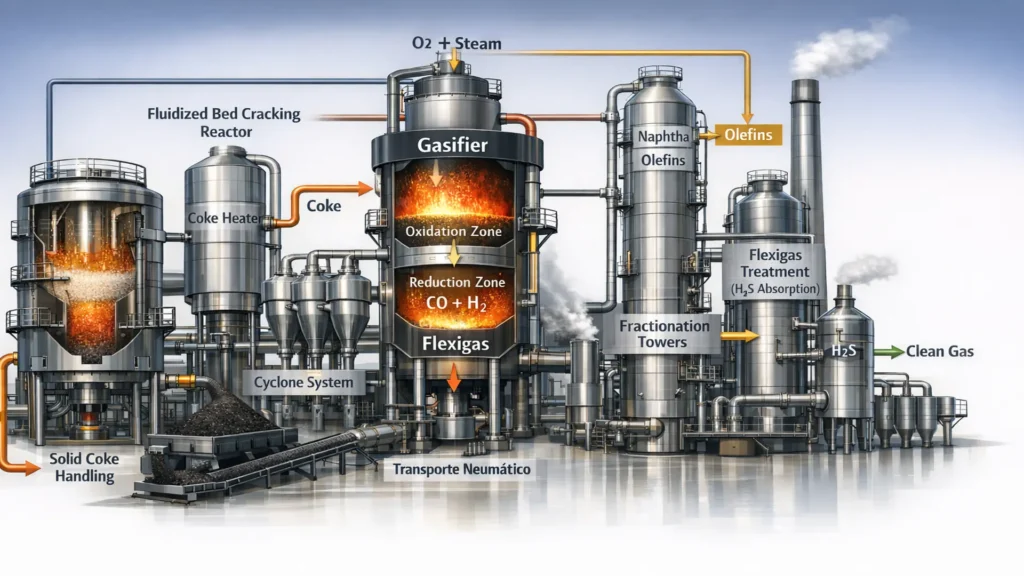

The Flexicoking process is an evolution of Fluid Coking, incorporating an integrated gasifier operating in a closed circuit. Its fundamental principle is based on three continuously coupled phenomena:

- Severe thermal cracking in a fluidized bed.

- Recirculation and heating of coke particles.

- Partial gasification of residual carbon.

The vacuum bottom fed to the system is atomized over a hot fluidized bed of coke particles, where thermal cracking occurs. This process generates lighter hydrocarbon vapors and deposits additional carbon on the solid particles. Subsequently, a significant fraction of this coke is sent to the gasifier, where it reacts with air and steam to produce a gaseous stream rich in CO and H₂ known as Flexigas.

The distinctive feature within deep residue conversion is that this process gasifies approximately 88 to 92% of the coke generated, drastically reducing the net production of solid coke compared to delayed coking.

Comprehensive description of process sections

The system operates continuously and can be analyzed as a set of interconnected subsystems that ensure thermal stability, conversion efficiency, and environmental control.

Feed and reaction

The vacuum bottom enters the reactor under carefully controlled pressure and temperature conditions. Proper atomization is critical to prevent agglomeration and ensure uniform contact with the hot fluidized bed.

Severe thermal cracking occurs in the reactor, producing:

- Light and heavy gas oils

- Naphtha

- Olefins

- Slurry oil

- Coke deposited on circulating particles

The generated vapors are separated by high-efficiency internal cyclones to minimize solid carryover.

Heating and gasification

The partially converted coke is transferred to the heater and subsequently to the gasifier. In the latter, rapid reactions occur in two differentiated zones.

In the oxidation zone, exothermic reactions such as the following take place:

C + 0.5 O₂ → CO

CO + 0.5 O₂ → CO₂

In the reduction zone, endothermic reactions predominate, such as:

C + H₂O → CO + H₂

H₂O + CO → CO₂ + H₂

The result is the generation of Flexigas, a low-calorific-value gas with high internal energy utility.

Flexigas conditioning and energy balance

Flexigas mainly contains CO, H₂, CO₂, H₂S, and traces of other compounds. Before being used as fuel or for hydrogen recovery, it must undergo treatment to remove acid compounds, especially H₂S.

Energy integration is one of the most relevant elements within the concept of deep residue conversion. Flexigas can be used in furnaces, boilers, or turbines, reducing the need for external fuels and improving the refinery’s energy self-sufficiency.

Fractionation and product recovery

Reactor vapors are sent to a fractionation column where the desired commercial cuts are separated. Subsequently, overhead products are compressed and treated in additional columns to recover fuel gas, C₃ and C₄ fractions, olefins, and heavy streams.

Light streams may undergo Merox treatment for mercaptan oxidation, improving their commercial quality.

Critical operational variables in deep conversion

Process performance depends on precise control of key variables such as:

- Reactor temperature

- Heater temperature

- Gasifier conditions

- Gas–solid ratio in the fluidized bed

- Recycle cut point

Optimization of these parameters allows adjustment of the balance between liquid production and gas generation, depending on operational strategy and market conditions.

Structural advantages over traditional schemes

From the perspective of deep residue conversion, Flexicoking offers differentiating advantages. Its ability to process streams with high metal and sulfur content broadens the range of crudes that can be processed without the need for conventional feed furnaces.

Integrated gasification reduces solid coke accumulation, decreases logistical issues associated with its handling, and improves environmental performance. The closed system minimizes fugitive emissions and allows better control of sulfur compounds.

In addition, the elimination of dedicated furnaces and thermal integration contribute to reducing relative investment compared to delayed coking schemes combined with external gasification units.

Environmental and strategic benefits of Flexicoking

Flexicoking stands out not only for its deep conversion capability of heavy residues but also for the environmental and strategic benefits it offers compared to traditional coking processes. One of the most relevant aspects is its closed-system operation, which minimizes fugitive hydrocarbon emissions throughout the entire processing cycle. This feature reduces the release of polluting compounds into the environment and contributes to compliance with stricter emission control standards, ensuring superior environmental performance without compromising operational efficiency.

The energy integration of the process constitutes another key strategic advantage. The gas generated by the partial gasification of coke, known as Flexigas, can be reused as an internal energy source, feeding boilers, furnaces, or gas turbines within the same industrial complex. This reuse decreases dependence on external fuels, reduces operating costs, and enables full utilization of thermal cracking byproducts, optimizing the overall efficiency of the refining system.

Additionally, its use to process residues with high carbon, sulfur, and heavy metal content without generating excess solid coke represents strategic value for modern refining. The reduction of solid byproducts decreases the need for coke storage and handling, simplifies internal logistics, and contributes to lower long-term environmental impact. Altogether, this process represents an advanced technology that combines energy efficiency, conversion maximization, and environmental control, consolidating itself as a strategic alternative for the sophisticated refining of heavy residues in contemporary industrial scenarios.

Importance in heavy crude refining

In the current refining landscape, characterized by increasingly heavier crudes and growing environmental restrictions, deep residue conversion is a determining factor for profitability and operational sustainability. This process makes it possible to:

- Maximize recovery of liquid fractions

- Convert most residual carbon into useful energy

- Reduce net solid coke generation

- Improve energy integration of the complex

This technology does not replace other upgrading schemes but represents a robust alternative when the strategic objective is to increase residue conversion and improve overall carbon utilization.

Conclusions

Flexicoking represents one of the most advanced technological solutions in the refining industry for deep conversion of heavy residues. Its integrated scheme of severe thermal cracking and partial coke gasification makes it possible to transform a significant fraction of residual carbon into useful liquid products and into a low-calorific-value fuel gas (Flexigas), which can be utilized as an internal energy source.

It drastically reduces the accumulation of final solid coke, one of the main byproducts of traditional coking processes, thereby improving the overall efficiency of heavy crude conversion schemes and increasing the energy integration of the complex, since the produced gas can be reused in combustion units or for hydrogen recovery.

From an environmental standpoint, the closed handling of the process and the reduction of fugitive emissions represent additional advantages compared to conventional coking technologies. Overall, it is a strategic alternative for the sophisticated refining of heavy residues, aligned with current needs for conversion maximization, energy optimization, and emission control.

References

- Gary, J. H., & Handwerk, G. E. (1980). Petroleum refining: technology and economics. Editorial Reverté.

- Wauquier, J.-P. (2004). Petroleum refining: crude oil, petroleum products, manufacturing schemes (Spanish version). Ediciones Díaz de Santos.

- Lluch Urpí, J. (2013). Petroleum refining technology and margin. Ediciones Díaz de Santos.