Table of Contents

- Concept and scope of failure analysis on metallic materials

- Failure analysis process in metallic materials

- Information collection: Basis of the technical diagnosis

- Visual inspection and macroscopic analysis

- Chemical and mechanical characterization of the material

- Fractography: reconstruction of the failure process

- Metallographic analysis and microstructural evaluation

- Complementary testing and advanced techniques

- Root cause diagnosis and preparation of the technical report

- Conclusions

- References

- Frequently Asked Questions (FAQs)

Failure analysis on metallic materials constitutes one of the most significant tools within materials engineering and asset integrity management. Its purpose goes beyond the simple identification of the point of rupture; it seeks to comprehensively understand the factors that led to the failure, the way in which the damage developed over time, and the conditions that allowed the component to reach a critical state.

In complex industrial systems, a metallic failure is rarely an isolated event. It is generally the final manifestation of a prolonged interaction among design, material selection, manufacturing processes, operating conditions, and service environment. For this reason, failure analysis must be approached as a systematic technical process, based on physical evidence, operational data, and sound metallurgical principles.

Concept and scope of failure analysis on metallic materials

From an engineering perspective, a failure analysis is a structured technical investigation that examines the loss of functionality of a metallic component, whether due to fracture, excessive deformation, corrosion, or progressive deterioration. The main objective is to determine the root cause of the damage, differentiating between primary mechanisms and contributing factors.

This approach makes it possible to establish whether the failure originated from an inherent material deficiency, a design error, an unforeseen service condition, or a combination of these factors. In highly critical contexts, failure analysis becomes a key input for operational and strategic decision-making.

Failure analysis process in metallic materials

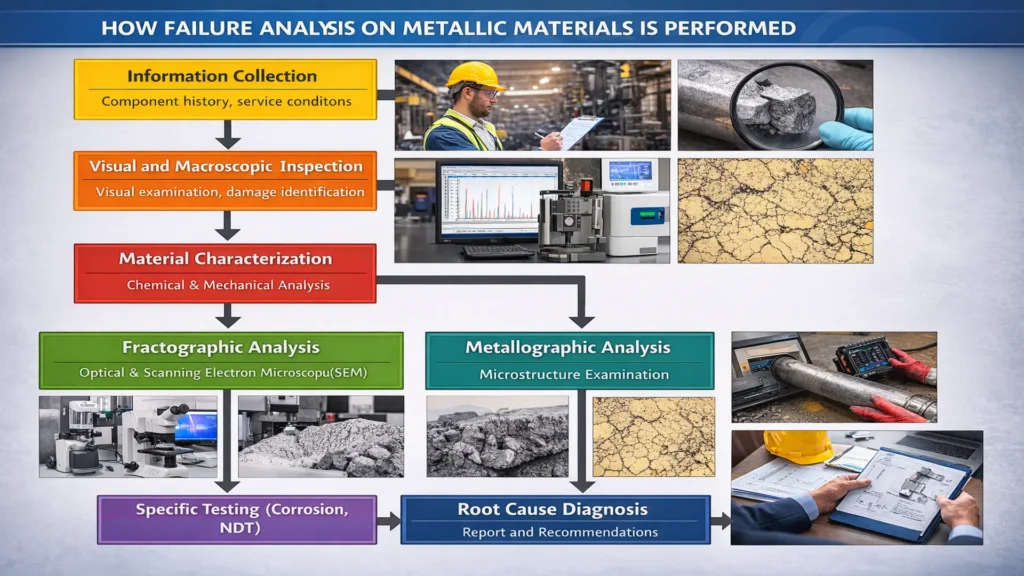

The failure analysis process on metallic materials combines several stages: collection of information on the component’s history and service conditions, visual and macroscopic inspection, chemical and mechanical characterization of the material, fractographic analysis using optical and electron microscopy, metallographic examination of the microstructure, specific corrosion testing and non-destructive testing (NDT), and finally root cause diagnosis with technical recommendations.

Each stage is complemented by images and data that allow understanding of the origin, evolution, and failure mechanisms, ensuring informed decisions to improve the reliability and safety of industrial assets. The following diagram shows the steps to be followed to carry out a failure analysis in metallic materials.

Information collection: Basis of the technical diagnosis

Every reliable failure analysis on metallic materials begins with an exhaustive collection of information prior to examination of the component. Experience shows that isolated metallurgical interpretation, without operational context, leads to incomplete or erroneous conclusions.

At this stage, the history of the component is reconstructed, considering its time in service, actual operating conditions, maintenance history, anomalous events, and modifications introduced throughout its service life. The correlation among mechanical loads, temperature, pressure, and chemical environment is essential to formulate initial hypotheses consistent with the observed behavior.

The review of drawings, material specifications, and manufacturing procedures also makes it possible to evaluate whether the component operated within the limits for which it was designed.

Visual inspection and macroscopic analysis

Visual inspection constitutes the first direct contact with the physical evidence of failure and, when correctly performed, provides information of great diagnostic value. Macroscopic examination makes it possible to identify the location of damage initiation, the direction of propagation, and the presence of plastic deformation, localized corrosion, or wear.

In metallic fractures, the general morphology of the surface can reveal whether the failure occurred suddenly or progressively. Surfaces with a granular, fibrous, or shiny appearance provide preliminary indications of the fracture mode and the level of energy involved in the final event.

This stage must be performed before any aggressive cleaning, since corrosion products and surface markings can be decisive in identifying the damage mechanism.

Chemical and mechanical characterization of the material

Verification of the chemical composition of the material is a fundamental step in failure analysis on metallic materials to confirm compliance with original specifications. Deviations in alloying elements, impurities, or residual contents can explain unexpected behavior with respect to corrosion, fatigue, or embrittlement.

In parallel, evaluation of the mechanical properties of the materials makes it possible to determine whether the material retains the characteristics expected in its original condition or whether it has undergone degradation during service. Changes in hardness, strength, or toughness may be associated with incorrect heat treatments, aging, hydrogen damage, or prolonged exposure to elevated temperatures.

Fractography: reconstruction of the failure process

Fractographic analysis constitutes one of the most precise tools for reconstructing the sequence of events that led to failure. Through optical microscopy and scanning electron microscopy, it is possible to identify morphological characteristics that reveal the dominant fracture mechanism.

The presence of fatigue striations, beach marks, or multiple initiation sites indicates progressive damage under cyclic loading. In contrast, cleavage surfaces or intergranular fracture are usually associated with brittle behavior, environmental embrittlement, or stress-assisted corrosion mechanisms.

Fractography allows, in many cases, determination not only of the failure mechanism, but also of the direction of propagation and the relative duration of the process prior to final collapse; it represents a fundamental section in failure analysis on metallic materials.

Metallographic analysis and microstructural evaluation

Metallographic study reveals the microstructure of the material and provides critical information about its metallurgical history. Through microscopic observation, non-metallic inclusions, segregations, undesirable phases, grain size, and evidence of overheating or prior deformation can be identified.

In corrosion-related failures, metallographic analysis is essential to detect intergranular attack, sensitization in stainless steels, or the presence of environment-induced microcracks. These observations make it possible to establish direct links between the microstructure and the identified damage mechanism.

Complementary testing and advanced techniques

When the failure mechanism requires it, specific tests are incorporated to confirm hypotheses formulated in previous stages. Corrosion tests, for example, help reproduce service conditions and evaluate the susceptibility of the material to phenomena such as pitting or stress corrosion cracking; this step is fundamental for the development of failure analysis on metallic materials.

Non-destructive techniques complement the analysis by allowing detection of internal defects, subsurface cracks, or discontinuities not visible to the naked eye, providing a more complete view of the condition of the component.

Root cause diagnosis and preparation of the technical report

The final stage of failure analysis on metallic materials consists of integrating all the results obtained into a coherent and technically substantiated diagnosis. The root cause is rarely limited to a single factor; in most cases, the failure is the result of the interaction among design, material, manufacturing, operation, and environment.

The technical report must clearly document the methodology applied, the relevant findings, and the conclusions reached, as well as propose recommendations aimed at preventing recurrence of the damage. A well-documented failure analysis becomes a tool for organizational learning and continuous improvement.

Conclusions

Failure analysis on metallic materials makes it possible to accurately identify the root cause of damage by integrating information from design, operation, manufacturing, and service environment. This approach prevents recurrence, optimizes material selection, and strengthens the reliability of industrial systems.

The combination of techniques such as fractography, metallographic analysis, chemical characterization, and specific testing provides a comprehensive view of material behavior, facilitating strategic and preventive decisions that reduce operational risks and costs associated with unplanned failures, constituting the main steps in failure analysis on metallic materials.

References

- Nobile, R. (2023). Failure Analysis in Metallic Materials. Metals, 13(8), 1374. https://doi.org/10.3390/met13081374

- Wouters, R., & Froyen, L. (1996). Scanning electron microscope fractography in failure analysis of steels. Materials Characterization. https://doi.org/10.1016/S1044-5803(96)00070-8

- Shiels, S. A., Bagnall, C., Witkowski, R. E., & Van der Voort, G. F. (1984). Corrosion, failure analysis and metallography. U.S. Department of Energy.

- (1999). Metallurgical Failure Analysis. In Practical Machinery Management for Process Plants (pp. 10–78). Elsevier. Chapter dedicated to metallurgical failure analysis of failures in metallic materials, highlighting the importance of identifying root causes and applying comprehensive analytical techniques for the prevention of future failures. ScienceDirect.

Frequently Asked Questions (FAQs)

What is a failure analysis on metallic materials?

It is a systematic process that investigates why a metallic component stopped functioning properly, identifying the factors that caused its deterioration or fracture.

What are the main steps in a failure analysis?

They include information gathering, visual inspection, chemical and mechanical characterization, fractography, metallographic analysis, complementary tests, and root cause diagnosis.

What types of failures can be detected?

Failures such as fatigue, corrosion, embrittlement, excessive deformation, wear, creep, or combinations of these mechanisms can be identified.

What is the purpose of failure analysis in the industry?

It is used to prevent future failures, improve material selection, optimize maintenance processes, and ensure the safety and reliability of critical equipment.