Table of Contents

Introduction

Digital radiography has undergone a significant transformation in industrial applications in recent decades. As technology advances, this technique becomes an essential tool in the inspection and quality control of products and components in a wide variety of industries. In this article, we will explore how digital radiography has revolutionized industrial applications and how artificial intelligence (AI) is playing a crucial role in this process.

Digital radiography in the industrial context

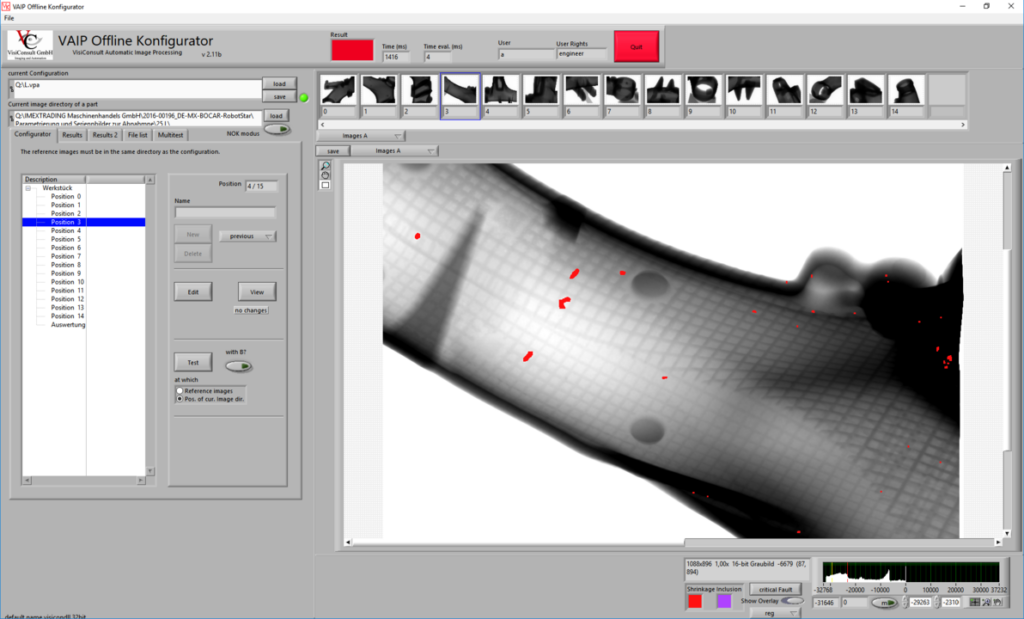

Industrial digital radiography is a non-destructive inspection method that uses x-rays or gamma radiation to create digital images of components and materials (Figure 1). Unlike traditional radiographic films, this technique provides significant advantages in terms of efficiency, image quality, and data storage.

Applications of digital radiography

Industrial applications of digital radiography span a wide range of industries, from electronics manufacturing to construction and aerospace. Some of the most common uses in industrial applications include:

- Quality control in manufacturing: Used to inspect components and assemblies for defects such as cracks, porosities, inclusions of foreign material, and discontinuities.

- Weld inspection: Digital radiography is essential in the inspection of welds in the construction and manufacturing industry, ensuring the structural integrity of welded parts.

- Detection of defects in electronic components: In the manufacturing of electronic products, it is used to detect defects in printed circuits, solders and encapsulations.

- Aerospace component evaluation: The aerospace industry uses digital radiography to inspect critical components such as engines, wings, and aircraft structures.

- Quality control in the automotive industry: It is used in the inspection of automotive components, such as engines, transmissions, and brake systems, guaranteeing the safety and quality of vehicles.

The Integration of AI in Industrial Digital Radiography

Artificial intelligence (AI) has played a key role in the revolution of digital radiography in industrial applications. AI has been incorporated into radiographic inspection systems to improve accuracy and efficiency in defect detection. Some of the ways AI has been integrated into this industrial tool include:

- Automated defect detection: AI algorithms can automatically detect defects in radiographic images, speeding up the inspection process and reducing reliance on human interpretation.

- Defect classification: AI can classify detected defects into specific categories, making it easier to identify problems and make decisions.

- Improved accuracy: AI algorithms improve the accuracy of defect detection by reducing false positives and negatives, which is essential in safety-critical applications.

- Trend and pattern analysis: AI can analyze large sets of radiographic inspection data to identify trends and patterns that might go unnoticed in manual analysis.

- Inspection parameter optimization: AI can suggest adjustments to radiographic inspection parameters to optimize image quality and defect detection.

Benefits of the Integration of AI in Industrial Digital Radiography

The integration of AI into industrial digital radiography brings a number of significant benefits to the industry:

- Improved efficiency: AI automates defect detection, speeding up the inspection process and reducing production time.

- Cost reduction: Early detection of defects with the help of AI avoids costly rework and increases production efficiency.

- Improved product quality: AI ensures more accurate inspection, resulting in higher quality and longer-lasting products.

- Improved safety: Detection of critical defects in industrial components ensures safety in a variety of applications, from vehicles to aerospace structures.

- Minimization of human errors: AI reduces the possibility of human errors in the interpretation of radiographic images, which is crucial in critical applications.

Artificial Intelligence: Challenges and Ethical Considerations

Despite the obvious benefits, the integration of AI into industrial digital radiography also poses important challenges and ethical considerations:

- Need for quality training data: AI depends on high-quality training data sets to function effectively. Collecting this data can be expensive and requires significant effort.

- Human interpretation vs. AI: AI is a powerful tool, but it should not completely replace human interpretation in critical applications.

- Data privacy and security: The collection and storage of radiographic inspection data raises concerns about data privacy and security, especially in applications where the information may be sensitive.

Conclusion

Digital radiography has undergone a revolution in industrial applications, driven largely by the integration of AI. This combination of technologies has improved efficiency, precision and safety in a wide variety of industries, from manufacturing to aerospace. While there are challenges and ethical considerations, digital radiography and AI continue to play a crucial role in quality control, defect detection, and improving production around the world.

As technology continues to advance, we are likely to see even more advancements in industrial digital radiography. AI’s ability to learn and adapt means that inspection systems will become increasingly accurate and efficient. This not only benefits companies by reducing costs and improving product quality but also contributes to the safety and reliability of a wide range of products and components, from automobiles to electronic devices.

However, it is essential to carefully address ethical considerations related to data privacy and security, and remember that while AI is a powerful tool, human interpretation and decision-making remain critical in critical applications. Ultimately, the integration of AI into industrial digital radiography represents an exciting technological advancement that promises to continue improving the quality and safety of the products we use in our daily lives.

References

- BANNARY AMMAN INSTITUTE OF TECHNOLOGY. Artificial intelligence for industrial Radiography; Consulted on October 25, 2023; https://www.bitsathy.ac.in/artificial-intelligence-for-industrial-radiography/

- MAXIMILIAN TOPP. How does Artificial Intelligence (AI) in NDT work?; Consulted on October 26, 2023; https://sentin.ai/en/ai-in-ndt/

- LENNART SCHULENBURG. Applying Artificial Intelligence (AI) in Digital Radiography; Consulted on October 27, 2023; https://www.ndt.net/article/ecndt2023/presentation/ECNDT2023_PRESENTATION_191.pdf