The human factor as the central axis in the management of offshore CALM Buoy SPM terminals

How the experience and decisions of engineers and operators support the design, installation, operation, and maintenance of SPM/CALM terminals.

How the experience and decisions of engineers and operators support the design, installation, operation, and maintenance of SPM/CALM terminals.

The ISPS Code strengthens maritime security and maritime cyber security, protecting ships and ports in accordance with the SOLAS Convention.

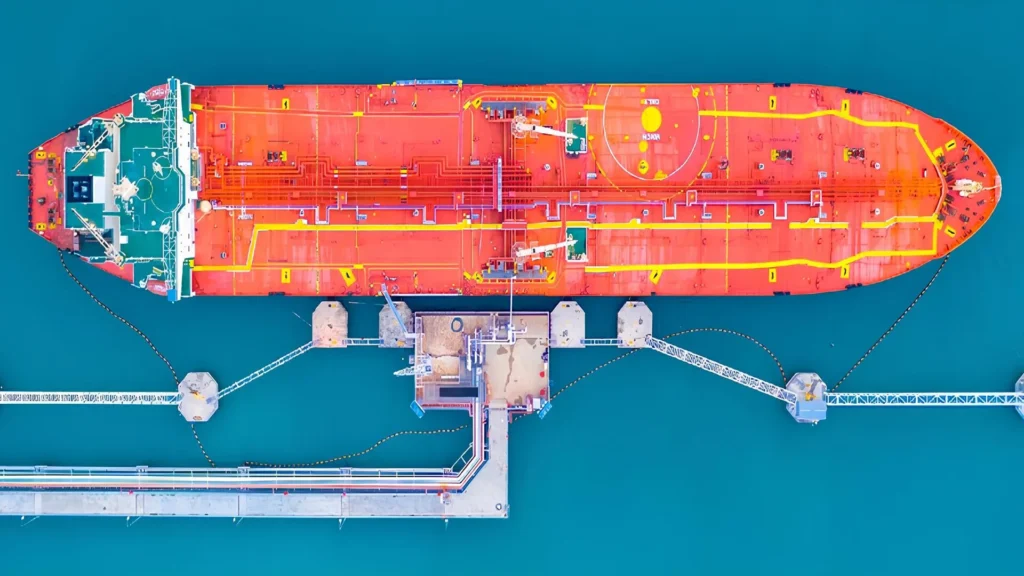

Mooring systems are a critical component for the safety and operability of offshore facilities, particularly at terminals with single buoys.

SLOM 2025, held in Panama, brings together operators of maritime oil terminals and single buoys in a space where technological innovation and sustainability converge with humanism.

Corrosion at liquid product port terminals is a critical risk that affects the safety and operability of docks and metal structures.

The transition to clean fuels at maritime terminals depends on both technology and human management.

Transpetro upgrades its offshore monobuoys with AI, GPS, and ROVs to increase operational safety and logistical efficiency.

LNG is now a key component of global energy security and sustainability. Inspenet explains why it is leading the energy transition.

Grupo HB offers construction and maintenance of docks, monobuoys and terminals, guaranteeing safe operation and regional regulatory compliance.

Data centralization makes it possible to anticipate bottlenecks, shorten dock times and ensure acceptable risk levels.