Internal pipeline corrosion constitutes one of the most complex and costly damage mechanisms affecting asset integrity in industries such as oil and gas, petrochemical, chemical processing, power generation, mining, and industrial fluid transportation. Unlike external corrosion, internal corrosion develops in dynamic environments that are difficult to characterize and highly dependent on operational variables such as fluid composition, flow regime, temperature, pressure, water content, presence of corrosive gases, and microbiological activity.

In this context, modern integrity management and risk-based maintenance (RBI) programs have evolved toward the use of continuous monitoring technologies capable of providing real-time or near-real-time information on internal corrosion rates and behavior. Within these technologies, corrosion coupons, Electrical Resistance (ER) probes, and Linear Polarization Resistance (LPR) techniques continue to be fundamental pillars, now reinforced by digital platforms, advanced data analytics, and non-intrusive inspection techniques.

The relevance of these advances will be a central topic of discussion at the AMPP Annual Conference + Expo 2026, where the industry converges to define the future of corrosion engineering and asset reliability.

Systems monitoring Internal pipeline corrosion

Pipeline systems transporting hydrocarbons, produced water, CO₂,H₂, amines, or saline solutions are exposed to various internal corrosion mechanisms that can cause wall thickness loss and severe localized damage. Controlling these phenomena not only requires constant monitoring but also reliable equipment capable of generating accurate data, such as those developed by Guided Ultrasonic Limited, globally recognized in the field.

Below, the technological innovations in corrosion coupons, ER, and LPR that have transformed systems management Internal pipeline corrosion.

Corrosion coupons in complex environments

Corrosion coupons represent one of the oldest and, at the same time, most reliable methodologies for evaluating Internal pipeline corrosion Their principle is based on the controlled exposure of a material representative of the pipeline to the process fluid, allowing mass loss quantification and calculation of average corrosion rates.

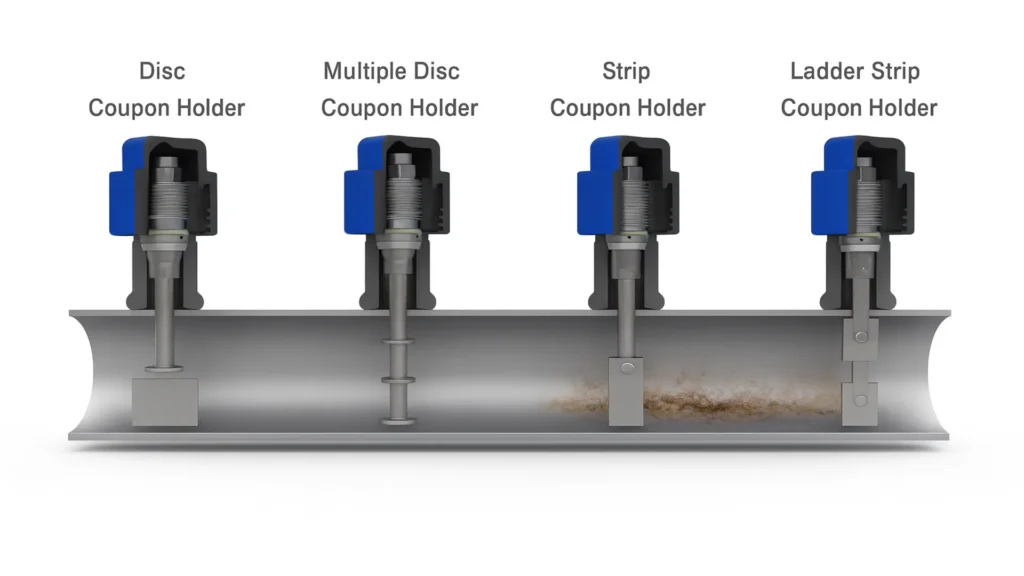

Recent innovations have overcome the historical limitations of this technique. Currently, coupons are designed with aerodynamic geometries, standardized surface finishes, and specific orientations to simulate real flow, shear, and deposition conditions. In addition, material selection is no longer limited to conventional carbon steel but includes low-alloy steels, stainless steels, and CRA (Corrosion Resistant Alloys) materials for comparative studies. The following image shows the types of corrosion coupons for pipelines.

The development of high-pressure retractable coupon holders, such as those referenced on specialized industry platforms, allows installation and retrieval without depressurizing the line, reducing operational risks and maintenance costs. This capability is critical in high-criticality systems where operational continuity is a priority.

Additionally, modern coupons are integrated into hybrid strategies, where mass loss results are correlated with electrochemical data and predictive models, improving diagnostic reliability.

Electrical Resistance (ER) Probes: High sensitivity

Electrical Resistance (ER) probes have become one of the most versatile tools for Internal pipeline corrosion monitoring . Their operating principle is based on measuring the increase in electrical resistance of an exposed metallic element, which directly correlates with the reduction of its cross-sectional area due to corrosion.

One of the main advantages of ER probes is their independence from the conductivity of the medium, making them ideal for systems with high hydrocarbon content, dry gases, or fluids with low aqueous phase, where electrochemical techniques such as LPR present limitations.

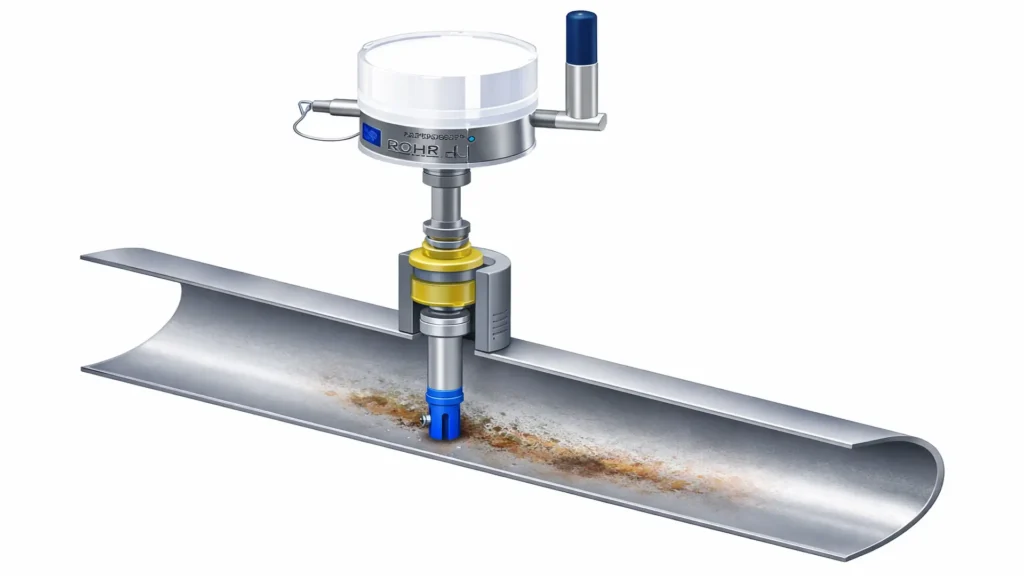

Recent innovations include high-resolution sensors capable of detecting thickness losses on the order of microns, as well as multi-element designs that allow differentiation between uniform and localized corrosion. The integration of these probes with digital acquisition systems and IIoT (Industrial Internet of Things) platforms facilitates remote monitoring, trend analysis, and early alarm generation in response to abrupt changes in corrosion rate.

From a predictive maintenance perspective, ER data allow evaluation of the effectiveness of inhibitor injection programs, changes in operating conditions, and transient events, providing key information for risk-based decision-making.

Linear Polarization Resistance (LPR): Electrochemical precision

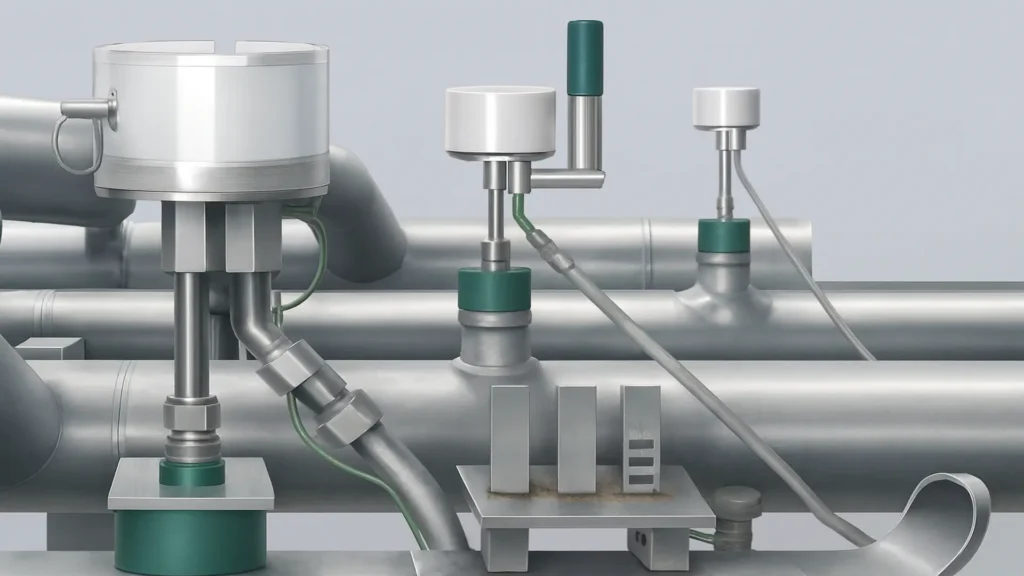

The Linear Polarization Resistance (LPR) technique remains one of the most widely used electrochemical methodologies for measuring instantaneous corrosion rates in conductive aqueous systems. Its basis lies in the relationship between the applied polarization current and the polarization resistance of the system, which is directly linked to the corrosion rate. The following shows this type of probes.

Currently, these LPR devices use sensors to evaluate general and localized corrosion rates; they are fully wireless systems with Bluetooth that offer wireless monitoring, configuration, and calibration through

Technological improvements in LPR have addressed historical challenges such as ohmic drop (IR drop), reference electrode stability, and interference from deposits or biofilms. Current systems incorporate automatic compensation, more robust electrodes, and filtering algorithms that enable more reliable measurements even under fluctuating operating conditions.

A relevant trend is the development of hybrid ER–LPR sensors that combine both techniques in a single device, expanding the application range and improving data interpretation in systems with frequent changes in fluid composition.

Integration: Advanced inspection and integrity validation

Localized internal corrosion monitoring must be complemented by inspection techniques capable of evaluating the overall condition of the pipeline. In this regard, guided wave ultrasonic solutions developed by companies such as Guided Ultrasonic Limited play a strategic role within integrity programs.

These technologies allow inspection of long pipeline sections from limited access points, detecting wall thickness loss, generalized corrosion, and volumetric defects without the need to remove insulation or perform extensive excavations. Correlating data obtained from coupons, ER, and LPR with guided ultrasonic inspection results enables validation of corrosion models, adjustment of monitoring frequencies, and optimization of mitigation plans.

In the following video, learn about the wide range of products and services offered by Guided Ultrasonics Ltd. Training (GULT)

Pipe inspection using guided wave technology.

Digitalization, artificial intelligence, and digital twins

Modern Internal pipeline corrosion is undergoing a transformation driven by digitalization. Monitoring systems no longer operate in isolation but are integrated into centralized platforms that leverage advanced data analytics, machine learning, and artificial intelligence.

The development of corrosion digital twins makes it possible to simulate system behavior under different operating scenarios, predict future degradation rates, and evaluate the effectiveness of mitigation strategies before implementation. This approach reduces uncertainty, improves asset reliability, and optimizes maintenance costs throughout the pipeline life cycle.

Relevant topic at AMPP Annual Conference 2026

The evolution of coupons, ER, and LPR, together with their integration with advanced inspection and digital platforms, represents a central axis for technical discussions at the AMPP Annual Conference + Expo 2026. These technologies enable a shift from a reactive approach to a proactive and predictive internal corrosion management strategy, aligned with international standards, sustainability, and operational excellence.

Conclusions

Effective management of Internal pipeline corrosion requires the integration of corrosion coupons, ER probes, and LPR techniques, complemented by non-intrusive inspection such as guided ultrasonics, to achieve reliable monitoring and a comprehensive evaluation of pipeline integrity.

The incorporation of digital technologies, predictive analytics, and risk-based maintenance (RBI) approaches enables anticipation of damage mechanisms, optimization of mitigation strategies, and extension of asset service life, aligning with the trends discussed at the AMPP Annual Conference + Expo 2026.

References

- American Association for Materials Protection (AMPP). (2023). Corrosion monitoring and control in oil and gas production. AMPP Publishing.

- Revie, R. W., & Uhlig, H. H. (2011). Corrosion and corrosion control: An introduction to corrosion science and engineering (4th ed.). John Wiley & Sons.

- ALSPI. (2024). Corrosion coupons and holders for internal corrosion monitoring. ALSPI Technical Resources. https://www.alspi.com/coupons.htm

- Guided Ultrasonic Limited. (2022). Long range guided wave ultrasonic testing for pipeline integrity management. Guided Ultrasonic Ltd. Technical Publication

Frequently Asked Questions (FAQs)

Why is internal corrosion in pipelines more difficult to control than external corrosion?

Because it depends on multiple internal operational variables that change continuously and are not always visible or accessible.

Are corrosion coupons still relevant compared to inline sensors?

Yes, because they provide direct physical evidence of metallurgical damage and are fundamental for data validation.

What is the main advantage of ER over LPR?

ER can operate in low-conductivity environments where LPR is not applicable.

How does guided ultrasonics contribute to internal corrosion management?

It allows evaluation of long pipeline lengths and validation of information obtained from localized monitoring.