Table of Contents

- Smart seals: IoT interaction and predictive maintenance

- Advanced materials: Driving operational performance

- Dry sealing technology

- Sustainability: Regulatory imperative and competitiveness

- Performance metrics: Quantifiable comparative analysis

- Artificial intelligence and design optimization

- A new paradigm for rotating equipment

- Conclusions

- References

The mechanical seal industry is undergoing an unprecedented transformation in its century-long history. Leading global manufacturers are not only monitoring technological advances, but also spearheading a revolution that is completely redefining how we conceive, design, and operate these critical components in rotating equipment.

The global mechanical seal market is experiencing robust growth, projected to reach $4.78 billion by 2029, with a compound annual growth rate of 5.9% during the period 2025-2029. This growth is not only quantitative; it represents a qualitative evolution driven by increasingly demanding industrial requirements, stricter environmental regulations, and the relentless pursuit of operational efficiency.

Leading manufacturers such as John Crane are investing significant resources in research and development to stay at the forefront of this transformation.

Smart seals: IoT interaction and predictive maintenance

The integration of Internet of Things technology into mechanical seals represents perhaps the most disruptive advance of the decade. Smart seals equipped with embedded sensors have transcended their traditional function of simply containing fluids to become active monitoring components that generate critical data in real time. Through this transformation, reliability engineers and maintenance technicians can detect failures effectively and accurately.

This transformative capability allows reliability engineers and maintenance technicians to anticipate failures with unprecedented accuracy. Sensors integrated into these advanced systems monitor multiple operational parameters simultaneously. Seal face temperature, characteristic vibrations, and differential pressure across the seal, and incipient leak patterns are continuously analyzed and transmitted to centralized asset management systems.

Smart seal monitoring.

The predictive capability of these systems reduces unplanned downtime by up to 30% according to recent industry studies. Machine learning algorithms analyze deterioration patterns and can identify subtle anomalies weeks or even months before a catastrophic failure occurs.

Operational reliability metrics

| Reliability Metrics | Conventional Seals | Smart Seals | Dry Seals | Maximum improvement |

|---|---|---|---|---|

| MTBF (Mean Time Between Failures) | 18-24 months | 36-48 months | 48-60 months | +250% |

| MTTR (Mean Time to Repair) | 8-12 hours | 4-6 hours | 2-4 hours | -75% |

| Equipment Availability | 92-95% | 96-98% | 98-99.5% | +7.5% absolute |

| Catastrophic Failure Rate | 8-12% | 2-4% | <1% | -90% |

| Failure Prediction Accuracy | Not applicable | 85-92% | 90-95% | New paradigm |

Advanced materials: Driving operational performance

Advances in materials science have unlocked operational capabilities that would have been considered impossible just a decade ago. Modern mechanical seals must operate in increasingly hostile environments: temperatures exceeding 400°C in geothermal applications, pressures greater than 500 bar in hydrogen compressors, and chemically aggressive environments that would quickly destroy conventional materials.

Improved variants of silicon carbide represent one of the most significant developments in seal face materials. Manufacturers have developed formulations with superior thermal properties that maintain their structural integrity in high-temperature applications where traditional carbides would fail.

These new compositions exhibit improved thermal conductivity, allowing for more dissipation of heat generated by friction at sealing interfaces. Thermal shock resistance has also improved dramatically, which is crucial for applications with severe thermal cycling.

Diamond-like carbon (DLC) coatings have emerged as a transformative technology for reducing friction and wear. These ultra-thin coatings, typically between 1 and 5 microns thick, provide extraordinary hardness that can reach up to 60 GPa in the most advanced tetrahedral amorphous carbon formulations. The coefficient of friction of DLC coatings can be 200 to 500% lower than traditional PVD tribological coatings, directly translating into lower heat generation, lower energy consumption, and extended seal life.

Dry sealing technology

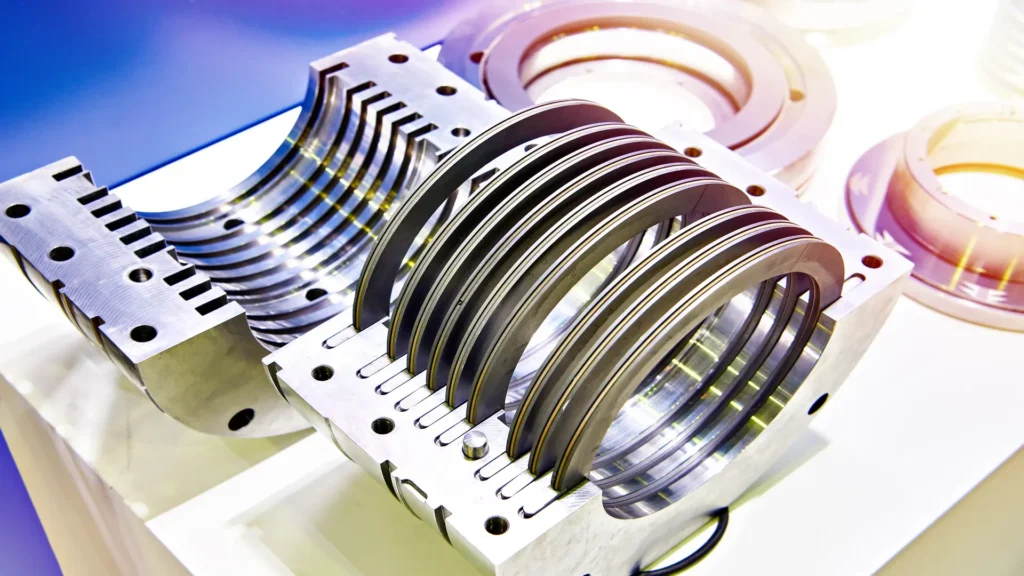

Dry seals or dry-running seals represent a paradigm shift in mechanical sealing philosophy. For decades, barrier fluid-lubricated seals dominated applications in the chemical and other process industries. However, advances in self-lubricating materials and tribological design have made dry seals not only viable, but also preferable in many critical applications.

The fundamental principle of dry seals lies in the careful selection of face materials with exceptional tribological properties that can operate without an external liquid film. Silicon carbide, tungsten carbide, and carbon graphite possess excellent self-lubricating characteristics, allowing them to maintain a low coefficient of friction even under dry contact conditions. Seal faces are lapped to an extreme degree of flatness, typically within helium light bands, ensuring optimal contact and sealing performance.

Dry seals eliminate the need for barrier fluid support systems, dramatically simplifying installation and reducing potential points of failure. There are no barrier fluid reservoirs to monitor, no auxiliary cooling systems to maintain, and no concern about product contamination from barrier fluid leakage. This simplicity translates directly into improved reliability and reduced maintenance costs.

In the chemical industry, where prevention of product contamination is critical, dry seals with nitrogen barriers have transformed operations. John Crane’s CK725 and similar systems use widely available plant nitrogen gas as a barrier agent for containment management. The inert gas minimizes any risk of product contamination while providing sufficient cooling for the seal faces. The dry contact face design incorporates features such as waste wells that capture particles and contaminants, preventing them from interfering with the seal.

Sustainability: Regulatory imperative and competitiveness

Sustainability has transcended from being a voluntary aspiration to becoming a regulatory imperative that drives fundamental innovation in sealing technology. Increasingly stringent environmental regulations, particularly in Europe and North America, coupled with ambitious corporate sustainability goals, are accelerating the adoption of eco-friendly sealing solutions.

Zero-emission designs represent the industry’s response to increasingly stringent fugitive emissions regulations. The European Union’s updated Industrial Emissions Directive for 2024 imposes harsher penalties for fugitive emissions, accelerating the adoption of dual-gas seals and seal-less magnetic drive pumps.

The US EPA’s LDAR (Leak Detection and Repair) programs now require real-time monitoring, driving demand for smart seals with embedded sensors capable of detecting incipient leaks before they become significant emissions.

Low-energy seals incorporate face technology designed to minimize friction and, therefore, energy losses. John Crane’s ECO-Seal series reduces friction losses by up to 25%, directly contributing to industries meeting their Net Zero 2050 targets. In large plants with hundreds of pumps and compressors, these seemingly modest reductions per individual seal add up to significant energy savings and carbon footprint reduction.

Performance metrics: Quantifiable comparative analysis

The adoption of advanced technologies in mechanical seals generates measurable benefits that directly affect operational profitability. The following comparative table presents consolidated data from multiple field studies and reports from leading manufacturers, providing a quantitative reference for decision-making in modernization projects.

| Sealing Technology | Downtime Reduction | Energy Savings | Extended Service Life | Maintenance Cost Reduction | Emissions Reduction | Optimal Application |

|---|---|---|---|---|---|---|

| Conventional Seals | Baseline (0%) | Baseline (0%) | 18-24 months | Baseline (0%) | Baseline | General low-criticality applications |

| IoT Smart Seals | 25-35% | 8-12% | 36-48 months | 20-30% | 15-20% | High-criticality plants, chemical industry |

| Dry Running Seals | 40-50% | 15-25% | 48-60 months | 35-45% | 90-95% | Chemical, pharmaceutical, vacuum applications |

| DLC Coated Seals | 20-30% | 35-45% | 60-72 months | 25-35% | 10-15% | High speed, high temperature, abrasives |

| Seals with Advanced Materials | 30-40% | 12-18% | 48-72 months | 30-40% | 20-25% | Extreme conditions, H₂, cryogenic |

| Hydrogen Seals (H2-Ready) | 35-45% | 10-15% | 36-48 months | 25-35% | 95-98% | Electrolyzers, H₂ compressors, clean energy |

| Seal-as-a-Service Systems | 45-55% | 18-28% | Contractually guaranteed | 40-60% | 25-35% | Critical operations, predictive maintenance |

Artificial intelligence and design optimization

Artificial intelligence is beginning to influence how mechanical seals are designed and optimized. Topological optimization algorithms can analyze complex load requirements and generate component geometries that minimize material while maximizing strength and stiffness. This technology, combined with additive manufacturing, enables the creation of lighter, more efficient seal components with geometries that would be impossible to design manually.

AI-driven systems are also improving seal selection. Historically, selecting the right seal for a specific application required experienced engineers consulting extensive catalogs and technical data sheets. Modern expert systems can analyze operational parameters, fluid conditions, space constraints, and reliability requirements to recommend optimal seal configurations. These systems continuously learn from field data, improving their recommendations over time.

By 2026, AI-driven seal optimization is expected to become standard in the oil and gas industry. Digital twins, virtual replicas of physical assets, enable simulation and testing of different seal configurations under various operating conditions without costly physical experimentation. This capability accelerates product development and enables large-scale customization to meet specific customer needs.

A new paradigm for rotating equipment

Mechanical seals have evolved from relatively simple components to sophisticated systems that integrate advanced materials, smart electronics, data analytics, and sustainability principles. By 2026, the mechanical seal industry is positional at the intersection of multiple transformative technology trends: digitalization, advanced materials science, additive manufacturing, artificial intelligence, and environmental sustainability.

Organizations that adopt these advanced technologies, invest in staff training, and collaborate closely with seal manufacturers on service-oriented business models will be better positioned to thrive in an increasingly competitive and regulated industrial landscape. The future of mechanical seals is not simply about preventing leaks; it is about enabling smarter, more efficient, and more sustainable operations that drive industrial competitiveness while protecting our environment for future generations.

For the pump engineer, field mechanical technician, and master of mechanics, these trends are not mere technical curiosities but practical tools that can dramatically improve equipment reliability, reduce operating costs, and meet increasingly important sustainability goals. The appropriate selection of sealing technology, informed by an understanding of these emerging innovations, can be the difference between reliable operation and costly failures.

Conclusions

Innovations in mechanical seals are redefining their role in the reliability and efficiency of rotating equipment systems. The integration of advanced materials, low-friction designs, and leak-reduction solutions not only enhances operational performance but also addresses growing demands for safety, sustainability, and regulatory compliance. Looking ahead to 2026, mechanical seals are evolving from passive components into critical elements for the integrity of essential equipment across sectors such as energy, oil and gas, chemicals, and industrial processing.

The trends shaping the development of mechanical seals toward 2026 point to increased digitalization, advanced standardization, and adaptation to increasingly demanding operating conditions. The incorporation of smart monitoring, along with optimized designs for high pressures, extreme temperatures, and complex fluids, will enable reductions in maintenance costs and downtime. In this context, the proper selection and application of mechanical seals becomes a strategic decision that directly impacts efficiency, reliability, and industrial competitiveness.

References

- https://www.researchgate.net/publication/346733745_Overview_of_Reciprocating_and_Centrifugal_Compressors

- https://www.pumpworks.com/how-to-install-mechanical-seal-in-centrifugal-pump