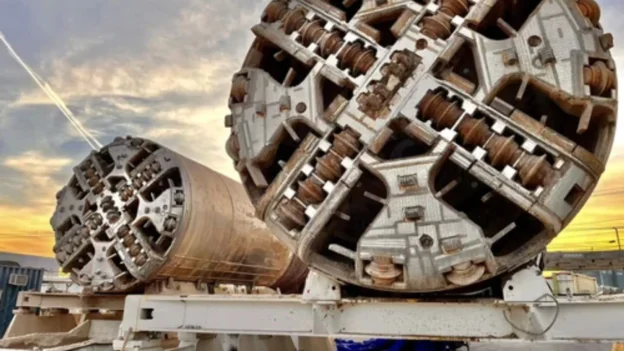

Elon Musk is once again shaking up the infrastructure arena with the unveiling of the Prufrock-4, a tunnel boring machine that aims to completely transform the subway excavation. This new generation of machine, developed by The Boring Company, promises greater speed, safety and efficiency in tunnel construction.

Musk’s tunnel boring machine digs without interruption

One of the most relevant advances of the Prufrock-4 is the full implementation of the Zero People in Tunnel (ZPIT) system. This feature allows the drill to operate without any worker being inside the tunnel, thanks to a remote control center that supervises all activity. The measure not only reduces labor risks, but also optimizes execution times and minimizes costs.

The company is also committed to continuous mining. Unlike traditional tunnel boring machines, which must stop every meter and a half to place liners, the Prufrock-4 integrates a system that installs precast concrete segments simultaneously with the excavation. This makes it possible to advance at rates exceeding 1.6 kilometers per week, well above previous models.

Porpoising technology and deployment in record time

Another highlight is its “porpoising” capability, a technology that allows the machine to be launched from a trailer into the subsoil in less than 24 hours. Upon completion, it emerges directly into a second vehicle without the need for additional work. This eliminates the need to build entry and exit pits or use heavy cranes, speeding up the start and close of each project.

The Boring Company, in addition to designing and manufacturing its own tunnel boring machines, also produces the liners, develops the Loop conveyor system and defines the standard size of its tunnels. This vertical integration allows it to control all aspects of the process, reduce costs per mile (aiming to go below $8 million) and execute projects in shorter time frames.

The next versions, Prufrock-5, 6 and 7, are already under development in Texas. Each new model aims to move closer to 24/7 continuous, fully automated and more economical excavation, marking a new stage in subway infrastructure development.

Source and photo: The Boring Company via X