U.S. startup Circularity Fuels has developed an electrical conversion unit capable of directly transforming biogas into electricity. biogas generated on dairy farms dairy farms into synthesis gas, an essential component for the production of sustainable aviation fuel (SAF).

This technology allows decentralized production with a capital cost 100 times lower than traditional methane reformers.

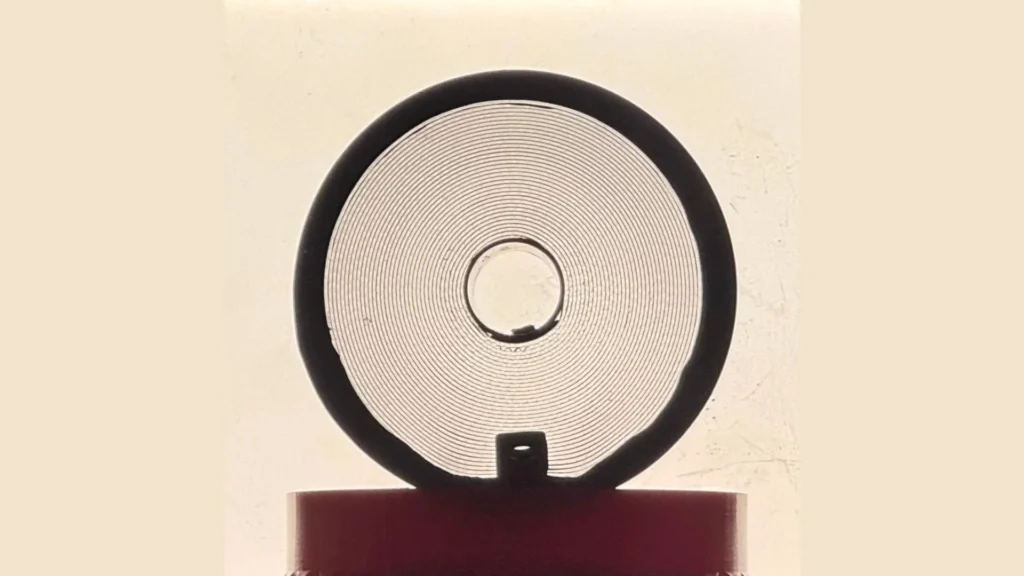

The Ouro reactor and waste transformation

On Ouroreactor, designed by Circularity, operates with standard electrical connection and does not require the usual costly pretreatment of biogas. Its innovative system allows direct conversion of methane and carbon dioxide contained in the manure, avoiding their release into the atmosphere and generating feedstock ready to be converted into PBS by Fischer-Tropsch synthesis.

The company has validated this operation on a California dairy farm, marking the first case of electric reforming of raw biogas from a covered lagoon digester.

Distributed jet fuel production

One of the main challenges in the adoption of renewable fuels has been infrastructure. Circularity proposes a distributed solution: by enabling the generation of liquid fuel directly on farms, dependence on gas grids is eliminated.

This fuel can be transported by road or rail, and can be easily integrated into existing logistics channels.

With more than 20,000 farms in the United States producing untapped biogas, the possibility of converting this waste into fuel represents a new source of revenue for the agricultural sector.

Impact on aviation and commercial deployment

Airlines face regulatory mandates to incorporate PBS, but currently only a fraction of what is needed is produced. Circularity estimates that, if its technology is implemented at all viable waste sites in the country, it could meet up to 70% of the nation’s demand for jet fuel.

The company will present its technology at the SAF Global Summit in London and plans a full demonstration of biogas production to SAF on a farm later this year. Initial commercial deployment is planned for 2026.

The company’s founder, Dr. Stephen Beaton, former head of the U.S. Air Force Petroleum Office laboratory, stresses that this technology democratizes the production of renewable fuelsby allowing livestock farms to become energy centers.

With catalysts adapted from the automotive automotive industryThe Ouro reactor maintains stable operation even in the presence of contaminants typical of agricultural biogas.

Source: Circularity Fuels via Business Wire

Photos: Circularity Fuels website