Marcin Lewandowski PhD, CEO of the Polish company us4us Ltd., shared, during his participation at the PANNDT conference, the technological vision that is transforming the way research and development of ultrasound imaging solutions with AI. With more than 25 years of experience in R&D projects, medical devices and software, Lewandowski leads a team committed to replacing the rigidity of hardware with the freedom of software-defined processing.

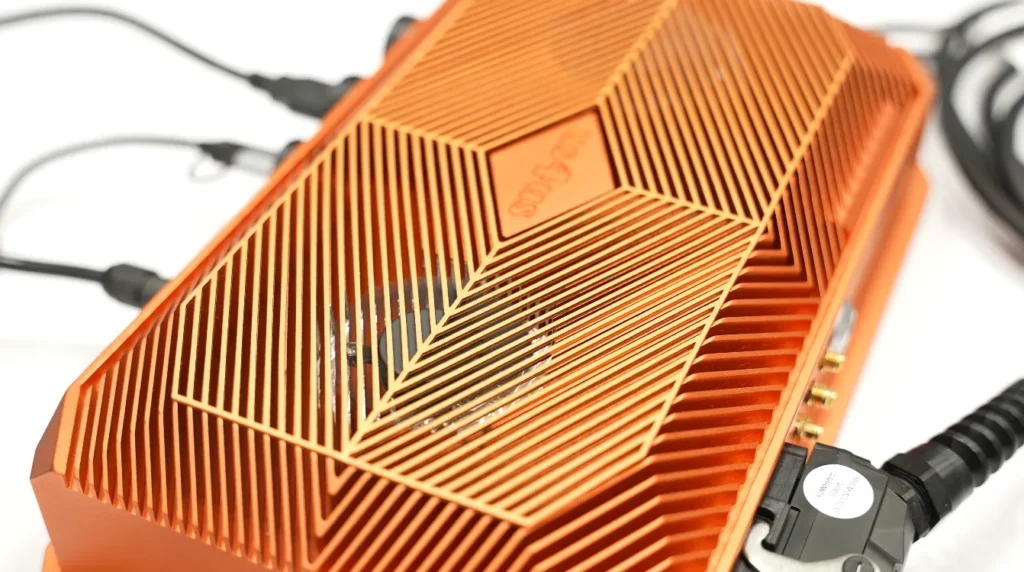

Founded in 2015, us4us is a company specialized in the development of ultrasound research and application platforms for medicine and industry. Its proposition is based on a flexible, scalable and integration-oriented approach of artificial intelligence. This significantly reduces development and transition times from research to commercial products.

Traditionally, ultrasound systems use fixed hardware components to perform tasks such as beamforming, which is essential for creating images from the echoes generated by ultrasound. These systems have a closed architecture, i.e., to modify how they work, parts of the device must be physically changed.

The company seeks to break with this paradigm by adopting a software-defined system, where most of these tasks are performed through code and algorithms using graphics processing units (GPUs). This brings with it multiple benefits:

In our devices, we use software-only processing, which harnesses the power of GPUs. This is therefore GPU-accelerated processing, which enables implementation in very complex algorithms.

Dr. Marcin Lewandowski.

Another major advantage of software processing is the direct integration with artificial intelligence. Being based on GPUs, us4us technology requires no adaptations or intermediate layers to run AI, resulting in native integration, where AI can operate as an active part of the ultrasound system, processing images in real time and providing automatic analysis with speed and accuracy.

The benefits of this integration include:

Exploring GPUs also allows us to integrate AI algorithms quite easily, as many open source frameworks for AI implementation are already GPU-ready. Therefore, their integration is quite seamless.

Dr. Marcin Lewandowski.

The company has designed its platforms to adapt to different development needs, using a modular architecture model, which allows the systems to scale according to the number of channels or modules required, facilitating the creation of prototypes and their subsequent implementation in final products.

We have modular and scalable platforms. Therefore, depending on the size of the system, the number of modules and channels implemented, it is relatively easy to expand or reduce the size of the system.

Dr. Marcin Lewandowski.

The versatility of the model has proven to be especially attractive for universities, research centers and startups in the health sector, which require agile solutions that are adaptable to their own pace of development.

Although us4us' initial focus has been on biomedical applications, the company sees enormous potential in the field of nondestructive testing (NDT). This type of application is essential in industrial sectors such as energy, petrochemicals, aerospace and aeronautics or advanced manufacturing, where materials, components and structures need to be evaluated without altering them.

In these environments, the us4us platform would allow:

Thanks to their modular architecture, AI ultrasound solutions can be easily adapted to the size, configuration and production volume required by each industry. In addition, its support for custom algorithms allows integrators and manufacturers to apply intelligent processing according to their own standards or operational needs.

The company operates under the quality standards required for medical devices in Europe, including ISO 13485 certification. This framework ensures that the design, development and production processes comply with international regulations.

As for the industrial field, us4us recognizes that there is still not as clear a certification strategy as in the healthcare sector, however, they are confident that collaboration with integrators and end users will facilitate that path.

The approach of us4us Ltd. combines three pillars that make the difference in the development of advanced solutions, software-defined processing, native integration with AI, and adaptability to industrial sectors. This synergy makes ultrasound with AI a strategic tool, both for accelerating medical innovation and optimizing complex industrial processes.

For more content on PANNDT 2025, visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.