The Welding Procedure Specification (WPS) provides basic guidelines for performing welded joints based on code requirements. It also provides the information necessary to guide the welder or welding operator and ensure compliance with code requirements, which standardize how each joint is executed: processes, consumables, parameters, preheating, and control tests.

Proper preparation and application increases quality, reduces rework, ensures regulatory compliance (AWS, ASME, ISO, API), and mitigates failure risks. This article explains what a WPS is, why it is essential, how it improves quality and safety, what standards govern it, and how it is applied in different countries and sectors.

What is WPS in welding?

WPS, or Welding Procedure Specification, is a technical document that systematically details the procedures and parameters necessary to perform welding safely and efficiently. Its main objective is to ensure that welds are performed uniformly, complying with quality standards and reducing the risk of defects that could compromise the integrity of equipment or pipes.

In the natural gas transportation industry, WPS not only ensures the mechanical strength of joints, but also facilitates pipeline inspection by providing clear criteria against which inspectors can verify the correct execution of each weld.

Importance of WPS in welding projects?

The Welding Procedure Specification (WPS) is essential in welding projects because it ensures that all metal joining processes are performed under controlled parameters, reducing the possibility of defects that could compromise the integrity of the pipeline. In natural gas pipeline systems, safety and reliability are critical. A well-defined WPS ensures that each weld meets the criteria for mechanical strength, adequate penetration, and absence of internal discontinuities.

This pipeline inspection procedure allows technicians to detect deviations more efficiently and accurately, reducing the likelihood of failures during operation. In addition, the WPS provides a standardized frame of reference, allowing different teams of welders and supervisors to work uniformly and consistently throughout the project.

How does the WPS ensure welding quality?

A well-defined WPS ensures that each weld is performed according to controlled parameters: electrode type, current, welding speed, joint type, and welder position. This minimizes variations, reduces internal and external defects, and ensures that joints meet the required safety standards. In addition, it allows for the planning of pipeline inspections and the establishment of acceptance criteria during non-destructive testing, such as ultrasound or X-ray. In this way, the WPS standardizes the welder’s work and integrates quality control throughout the entire service life of the pipeline.

Process control and error reduction

A well-written WPS leaves little room for interpretation: it avoids the use of incorrect parameters or consumables that are not compatible with the base metal, prevents unwanted metallurgical mixtures, defines the technique (weave, root, and filler beads), surface preparation, and pass sequence to control distortion. The result: joints with reproducible mechanical performance, suitable for service according to specifications.

Improved safety and regulatory compliance

Inconsistent welds can lead to leaks, collapses, or unscheduled shutdowns. WPS increases the operational safety factor by standardizing how cracks, lack of penetration, and thermal embrittlement are prevented, and how they are validated with tests (macro attack, traction, bending, impact, hardness, or corrosion, as applicable).

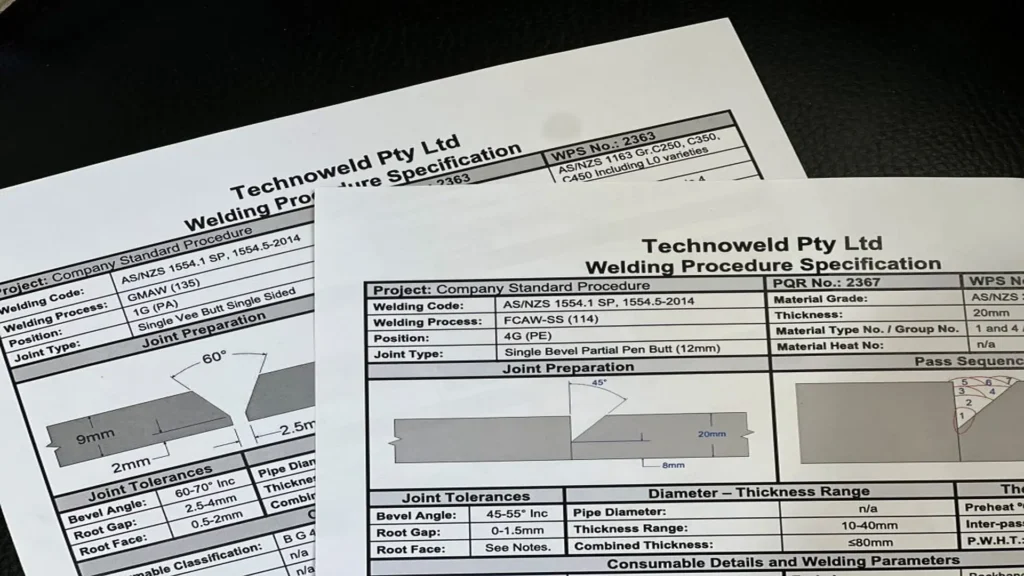

What a WPS should contain

A WPS should contain detailed information organized in such a way that welders and supervisors can follow the procedure without ambiguity. Typical elements include:

- Procedure identification: unique code or reference that allows it to be linked to the project and welding records.

- Base material and consumables: type of steel or alloy of the pipe, and the corresponding electrode or welding wire.

- Joint preparation: dimensions, beveling, cleaning, and alignment required before welding.

- Welding parameters: current, voltage, feed rate, type of shielding gas, and welding position.

- Pass sequence: description of the order and number of passes required to achieve the final weld.

- Pre- and post-heating requirements: if applicable, to reduce residual stresses and the risk of cracking.

- Acceptance criteria: quality standards, permissible tolerances, and applicable inspection methods.

This content ensures that welding is performed uniformly and that any pipe review or inspection can compare the execution with the planned parameters, ensuring compliance and operational safety.

International standards for WPS in the industry

Standards and norms

- ISO 15614 (series): requirements for the qualification of welding procedures for metallic materials, by process and material family; establishes tests to validate the WPS.

- ASME Section IX: qualification of welding and brazing procedures for pressure components (boilers, vessels, and pipes).

- AWS D1.1: guidelines for welding structural steel in metal construction; includes WPS qualification requirements.

- EN ISO 9606 (series): qualification of welders by process and position; ensures the competence of the performer in accordance with the WPS.

- API 1104: welding in pipelines and related facilities in oil and gas; establishes qualification of procedures and welders for transport lines.

Application by region and sector

In the US, ASME IX, AWS D1.1, and API 1104 predominate for energy, construction, and oil & gas. In Europe, ISO 15614 and EN ISO 9606 are widely required in automotive, aerospace, and marine applications. In Asia and the Middle East, international and local standards coexist, combined according to regulatory and market requirements.

Table 1. International standards related to WPS

| Standard | Scope & typical sectors | What it qualifies | Highlights | Considerations |

|---|---|---|---|---|

| ISO 15614 (series) | Metallic materials; global use (manufacturing, shipbuilding, general fabrication) | WPS (procedure) via destructive/NDE tests | Harmonized approach; detailed essential variables by process/material | May require multiple tests for multi-process/multi-material ranges |

| ASME Section IX | Pressure equipment (boilers, pressure vessels, piping) | WPS/PQR and welder/brazer qualifications | Widely accepted in power & process; strong traceability | Focused on pressure boundary; cross-recognition may need mapping |

| AWS D1.1 | Structural steel (buildings, bridges) | WPS and welder for structural applications | Clear acceptance criteria for structural welds | Primarily structural; limited for pressure service |

| EN ISO 9606 (series) | Global, with strong use in Europe; multiple processes | Welders (skills) by process, position, material group | Aligns with ISO 15614; portable qualifications | Periodic confirmation/maintenance required |

| API 1104 | Oil & gas pipelines and related facilities | WPS and welder for line pipe | Fit-for-purpose for field pipeline welding | Not intended for structural steel or pressure vessels |

How to implement and maintain an effective WPS?

To maintain an effective WPS, it is necessary to:

- Record and archive inspection and test results to ensure traceability and support during audits.

- Train personnel on documented procedures.

- Periodically review and update parameters according to new regulations or materials.

- Integrate the pipe inspection plan into the procedure, ensuring that all tests and verifications are performed correctly.

Conclusions

The Welding Procedure Specification (WPS) is an indispensable tool for ensuring quality and safety in welding projects. It provides a standardized approach that ensures consistency, compliance with international codes, and greater reliability of welds. Companies that adopt rigorous WPS protocols can reduce errors, improve safety, and demonstrate regulatory compliance.

As industries evolve and technologies advance, the relevance of WPS will only increase. Organizations that integrate robust WPS practices will be better positioned to meet international standards and ensure the long-term success of their welded structures.

References

- American Petroleum Institute. (n.d.). API Standard 1104: Welding of Pipelines and Related Facilities. API.

- American Society of Mechanical Engineers. (n.d.). ASME Boiler and Pressure Vessel Code, Section IX: Welding, Brazing, and Fusing Qualifications. ASME.

- American Welding Society. (n.d.). AWS D1.1/D1.1M: Structural Welding Code—Steel. AWS.

- International Organization for Standardization. (n.d.). ISO 15614 (series): Specification and qualification of welding procedures for metallic materials. ISO.

- International Organization for Standardization. (n.d.). EN ISO 9606 (series): Qualification testing of welders—Fusion welding. ISO.

- GIIS Gamma UK. (n.d.). The Importance of Welding Procedure Specification. Recuperado el 21 de agosto de 2024, de https://gammax.co.uk/the-importance-of-welding-procedure-specification/