Introduction

Inspection and maintenance in the energy industry have always been challenging and costly tasks. With the introduction of drones, this situation has changed dramatically, allowing for faster, safer, and more cost-effective inspections. In this article, four success cases are presented where drone inspection has revolutionized assessments in the energy industry, improving efficiency and safety.

The drone revolution in the energy industry

The implementation of drones in the energy industry has brought with it a number of benefits. Among them are:

- Cost reduction: Drone inspection significantly reduces the costs associated with inspection and maintenance, eliminating the need for expensive climbing equipment and platforms.

- Increased safety: Drones can access hazardous areas without putting workers’ lives at risk.

- Increased efficiency: Drone inspections are much faster and can identify problems in real-time, facilitating a rapid response.

Drone inspection success cases in the energy industry

Success case 1: Internal inspection of wind turbine blade

Wind farms, often located in remote and difficult-to-access areas, require regular inspections to ensure optimal operation. Traditional inspections are slow and dangerous, as technicians must climb the turbines.

The Danish power company Orsted tested the Elios 2 for an inspection of an offshore wind turbine blade and found that it helped them inspect 40% of the blade length, improve safety, and halve the time required for the inspection1. Figure 1 shows the inside image of the blade taken from the Elios 2 drone. Today the new Elios 3 model incorporates many improvements, enhancing the use of the inspection drone in many confined space applications with high image resolution and scanning power.

Results

- Access: Using the Elios 2 for internal inspection of a wind turbine blade allowed inspectors to capture visual data from 40% more of the blade surface compared to a manual inspection.

- Safety: The implementation of the Elios 2 for internal inspection of wind turbine blades allowed inspectors to obtain visual data from 40% more of the blade than could be achieved with a human inspection.

- Speed and efficiency: The Elios 2 allowed inspectors to cut the time required to collect visual data in half. For wind farm operators, every second a turbine is stopped represents a potential loss of revenue, so the increased inspection speed also means increased revenue.

Wind turbine interiors inspection with Elios 2.

Success case 2: Drone inspection of hydrocarbon gas piping systems for leak detection

For companies in the oil and gas sector, an important part of their safety work consists of monitoring hydrocarbon gas service pipeline systems for leak detection and correction. However, due to the wide and complex distribution of pipelines, traditional manual inspection methods present problems of performance, personnel risk, and accessibility, among others.

At a petrochemical complex in Guangzhou China, Soarability provided a suite of Sniffer4D gas detection systems designed specifically for pipeline inspection and mounted on Matrice 350 RTK drones.

At the site, the survey team operated the drone in such a way that it flew and scanned the area within a 3-meter radius above the pipelines. Meanwhile, they paid close attention to the concentrations of hydrocarbon gases, mainly methane, and the gradient changes shown by using Sniffer4D Mapper2 software. Figure 2 shows a photograph of the Matrice 350 RTK drone equipped with the Sniffer4D thermal camera, flying over oil and gas pipelines.

Results

- Efficiency: It allows to overcome terrain limitations and other factors, to choose the route and direction of exploration with flexibility, to detect hard-to-reach places and to cover the inspection area over a greater range.

- Safety: Safety risks were reduced for technical personnel evaluating and discovering, investigating, and managing emergencies in a timely manner.

- Costs: It provides short set-up time and fast start-up and saves time and labor costs.

- Versatility in data collection and analysis: The drone-mounted Sniffer4D gas detection system can directly capture images, videos, and gas concentration distributions from around the pipeline and then transmit the information to the inspection team, management team, and technical expert away from the scene, providing them with crucial reference for decision-making.

- Fast survey report generation: The report contains key information such as detection time, the maximum concentration of a single grid/single point, corresponding latitude and longitude, etc., and is attached with an intuitive map of concentration distributions.

Success case 3: Drone inspection of solar power plant

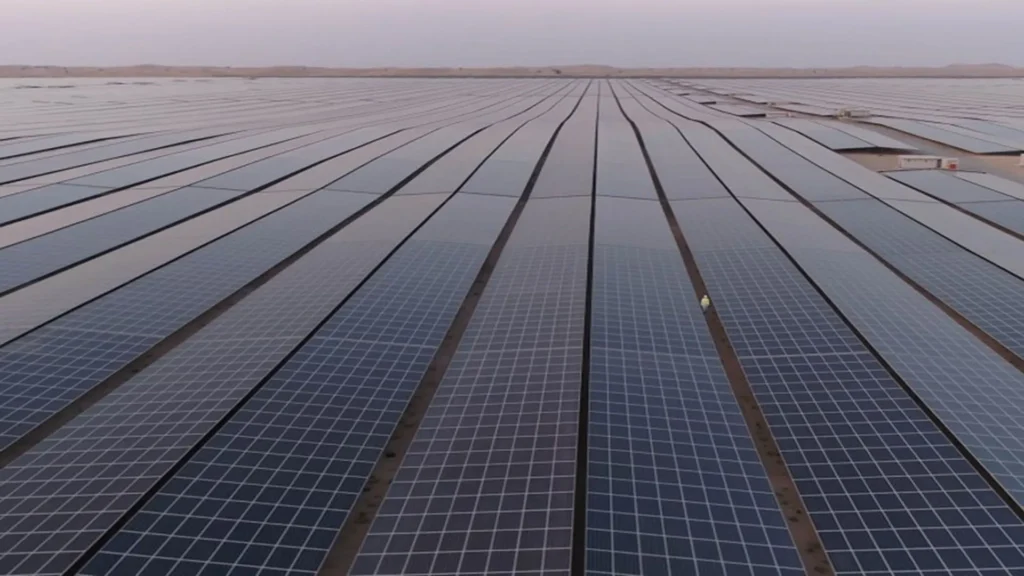

Solar plants require regular inspections to ensure that the solar panels are in good condition and operating at maximum capacity. Manual inspections are tedious and time-consuming. Inconsistent or inaccurate inspections can cause damage, which in turn leads to lost efficiency and profits. In the case of solar, this is even more critical, as there are large communities that rely on them to operate smoothly.

One location for solar power plants is the Middle East, where large desert areas with no residents are ideal for solar panel farms. In addition, the almost perpetually clear skies allow for constant power generation.

Noor Abu Dhabi, located near the city of Sweihan, is 8 square kilometers in size and has more than 3.2 million solar panels. It is currently the largest solar power plant in the world located at a single site. Pix4D’s distributor and partner, Falcon Eye Drones (FEDS), was contracted to track and monitor monthly progress during the plant’s construction with accurate, high-resolution drone mapping. The desired results included maps, videos, and individual images3 (figure 3).

Results

Efficiency: The advantage of using drones was that they could complete the survey in one day and produce actionable data the next day, in contrast to traditional methods which would have taken weeks, the drone can quickly fly over the site, collect a complete data set without staff having to walk for hours.

The generation of photograms using drones generated accurate and useful results that have been used in the ongoing management of this immense site. Figure 3 shows an image of the solar farm project under construction.

Success case 4: Drone inspection of transmission towers

Transmission towers, which transport electricity over long distances, require regular inspections to prevent failures. Traditional inspections are dangerous and time-consuming, and in other cases, to overcome this low efficiency, the use of helicopters is required, which substantially increases the cost of the inspection.

An electric utility company began using drones equipped with high-resolution cameras and infrared sensors to inspect its transmission towers. The drones can fly close to the towers and capture detailed images of critical components.

Leading engineering firm Keltbray, a specialist provider of overhead power line and substation services, is using drones to double inspection efficiency and reduce carbon emissions by nearly 50%.

Keltbray has invested in the DJI M300 RTK platform and its ecosystem of powerful cameras to collect higher-quality data, faster and more securely than ever before.

The P1 photogrammetry camera and L1 LiDAR sensor are integrated into the drone to build highly detailed maps, models and point clouds to improve mission planning and address the challenges associated with traditional power line construction methods4.

The H20T high-resolution thermal imaging camera is also integrated into the vehicle to perform thermal evaluations of power lines for early detection of defects or thermal anomalies that could compromise the continuity of power supply.

Results

- Efficiency: Reduction of inspection time by up to 50%.

- Safety: Elimination of risk for workers who no longer need to climb towers.

- Cost: Significant decrease in operating costs due to the efficiency of drones.

Future of drones in the energy industry

The success of drones in energy infrastructure inspection has demonstrated their potential to revolutionize the industry. As drone technology advances, its use is expected to expand further, incorporating artificial intelligence and real-time data analysis to further improve efficiency and safety.

Conclusion

The implementation of drones in the inspection of the energy industry has been a game changer, providing relevant results in terms of efficiency, safety and costs. Success cases in the inspection of wind farms, pipelines, solar plants, and transmission towers demonstrate the value and potential of this technology. As the industry continues to evolve, drones will continue to play a crucial role in improving operations and maintenance of critical infrastructure.

References

- VANTIT. Internal inspection of wind turbine blade; Accessed June 03, 2024. https://vantit.com/inspeccion-de-aerogeneradores/

- ACRE SURVEYING SOLUTIONS. Pipeline inspection with the Sniffer4D drone gas detector; Accessed on June 03, 2024. https://grupoacre.es/inspeccion-de-tuberias-con-el-detector-de-gas-para-dron-sniffer4d/

- PI X 4D. Saving work weeks: inspection of a solar farm; Accessed June 04, 2024. https://www.pix4d.com/es/blog/inspecciones-de-energia-solar-con-drones/

- DJI. Case study: Keltbray doubles its efficiency with the use of drones for power line inspection; Accessed on June 04, 2024. https://djiarsmadrid.com/es/blog/dji-news/caso-de-estudio-keltbray-duplica-su-eficacia-con-el-uso-de-drones-para-la-inspeccion-de-lineas-electricas.