The electromagnetic spectrum of microwaves, known for their domestic applications and satellite communications, has also found promising ground in the area of reliability such as Non-Destructive Testing. This method, which has gained recognition for its efficiency and versatility in the evaluation of non-metallic dielectric materials and delves into a wide spectrum of applications in various disciplines.

Microwave testing , called Microwave Technology Testing by ASNT, has been developed specifically for the inspection of non-conductive materials (dielectrics), such as plastics, elastomers, ceramics, glass fibers, composite materials, or others.

The previous development of this technology in domestic and telecommunications applications has facilitated its adaptation in the discipline of Non-Destructive Testing at a lower cost. In this article, we will explore the innovative techniques and applications of this technology.

Principle of the Microwave Test Method

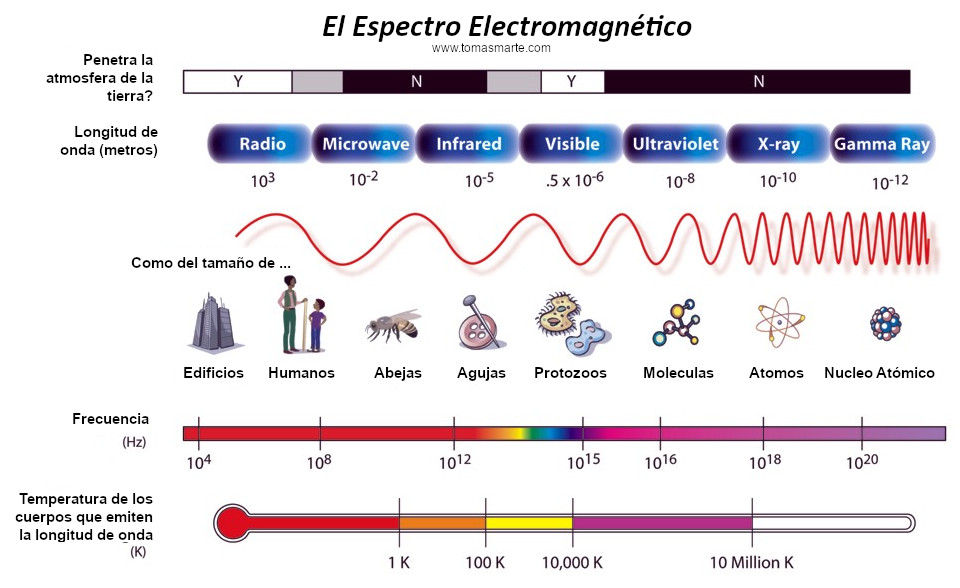

Like light and x-rays, microwaves are electromagnetic waves. Their frequencies extend from 300 MHz to 300 GHz and lie between radio waves and the far infrared (see figure 1).

The operation of the test is based on the concept of electromagnetic wave interferometry. Through a transmitter, a beam is emitted towards the piece under test and in those interfaces where there is a change in relative permittivity (dielectric constant), reflections of the signal occur. Changes in the dielectric constant can be caused by physical or chemical changes in the material, such as delaminations, cracks, voids, impurities, lack of adhesion, lack of fusion, humidity or liquid ingress, mechanical damage or other types of damage.

Similar to ultrasound testing, microwave testing can be performed in reflection mode and transmission mode.

Limitations of Non-Destructive Testing in the inspection of non-metallic dielectric materials

Some Non-Destructive Testing has been used in the inspection of non-metallic dielectric materials, they present limitations that are advantages for microwave testing. The limitations are described below:

- Ultrasound (UT): It cannot be used on rubber or soft plastics because they absorb the energy almost entirely. Additionally, in the network of layers of a composite material, the signal-to-noise is very disproportionate. Additionally, if the transmit-receive technique is used, access from both sides of the component is required, which is not always feasible.

- Magnetic Particle and Eddy Current Test, or any other electromagnetic method: Not applicable in the inspection of composite materials because they are inherently dielectric.

- Radiography: Except for the use of non-conventional low energy sources, they do not offer 100% reliable results because the defects that affect this type of materials do not significantly change the density of the materials. On the other hand, the forecasts associated with the risks due to exposure to ionizing radiation affect production activities in the field.

Applications of the Microwave Test Method

The versatility of microwave non-destructive testing has found significant applications in the characterization of materials, opening new possibilities in scientific research and as a method within the discipline of Non-Destructive Testing. Several of its main applications are listed below:

- Determination of dielectric properties: This application emerges as a key application in the characterization of materials such as the dielectric constant, of great importance in the electronic industry, telecommunications and development of advanced materials.

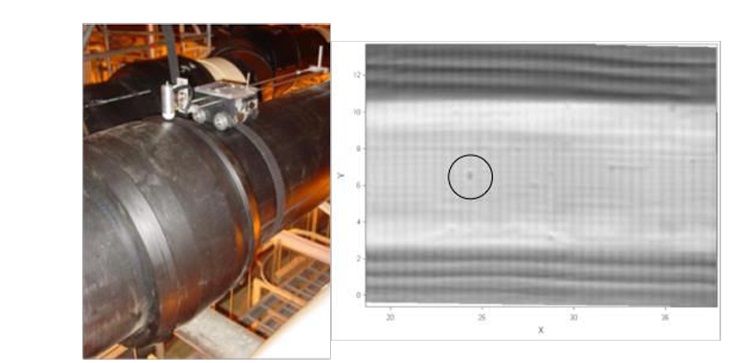

- Inspection of joints in high-density polyethylene pipes: Allows you to quickly detect images of cold joints in the welded joints of HDPE pipe sections (see figure 2).

- Metrology: This test is essential to measure the thickness of dielectric non-metallic materials. Whether monitoring the thickness of composites, ceramics or polymers, this technology offers a non-invasive solution. This application is particularly beneficial in industries such as aerospace and manufacturing, where material thickness plays an important role in structural integrity.

- Condition Monitoring: By analyzing how microwaves interact with materials, it is possible to identify structural weaknesses, corrosion or other defects. This proactive approach allows timely interventions, preventing failures and guaranteeing the useful life of structures, being of great importance in areas such as the aerospace industry, where the highest standards of safety and reliability are required.

- Evaluation of fiberglass containers: Allows you to quickly and accurately identify internal defects, accessing only the external face of the equipment.

- Detection of defects in composite materials: The penetration capacity of microwaves allows the detection of internal defects in composite materials, such as cracks or delaminations, being essential in the evaluation of structures in the aerospace industry.

- Inspection of windmill blades: The use of renewable means for energy generation has marked global growth, with one of the most used options being to take advantage of wind energy through enormous wind turbines. The test allows us to know the internal arrangement of the different layers of the material, observing, for example, excesses or lack of resin, even roughness in the internal volume of the piece that act as stress concentrators, generating delaminations that can cause failures during processing. operation of wind turbines.

- Inspection of concrete and other construction materials: In civil engineering, this Non-Destructive Test is used to inspect the quality of concrete and other construction materials. This offers an efficient and non-invasive alternative to evaluate the strength and durability of existing structures.

Challenges and future of Microwave Non-Destructive Testing

Although these tests have proven to be a valuable tool, they face challenges such as limited spatial resolution and the need to adapt to a variety of materials. Continued research is focused on overcoming these challenges and making the most of the potential of this technology.

In the future, microwave non-destructive testing is expected to evolve towards more specific and advanced applications, integrating complementary technologies to improve resolution and precision.

Conclusion

Microwave Non-Destructive Testing has proven to be an innovative technology with diverse and promising applications. From materials characterization to structural integrity assessment, this technique not only preserves the integrity of samples, but also offers detailed and considerable information across a variety of disciplines. As research and development continue, an increase in adoption and expansion of applications is likely, cementing the assay as an important tool in research and industry.

References

- ALESSANDRO DEMMA, ALESSANDRO BORDIGNON, MASSIMILIANO ROSSI, GUILLERMO GARCÍA. Non-Destructive Testing using Microwaves: State of the Art; Consulted on November 9, 2023; https://www.ndt.net/article/panndt2019/papers/9_Alessandro_Demma.pdf

- XCEL INSPECTION. Microwave. Consulted on November 10, 2023; https://xcelinspection.com/prod/sistema-microondas/

- JOHANN HINKEN. Microwave Testing (µT): An Overview; Consulted on November 12, 2023; https://www.ndt.net/article/ndtnet/2017/1_Hinken.pdf

- D. FAKTOROVA. Microwave Nondestructive Testing of Dielectric Materials; Consulted on November 12, 2023. https://core.ac.uk/reader/8986520