During the NISTM 2025 event, Stephanie Nolan, vice president of Sales and Marketing at Square Robot Inc. shared how her company is redefining the process of tank inspection through the use of autonomous robotics. The company, which specializes in industrial storage tank solutions, presented its underwater robot that allows inspections to be performed while tanks remain operational.

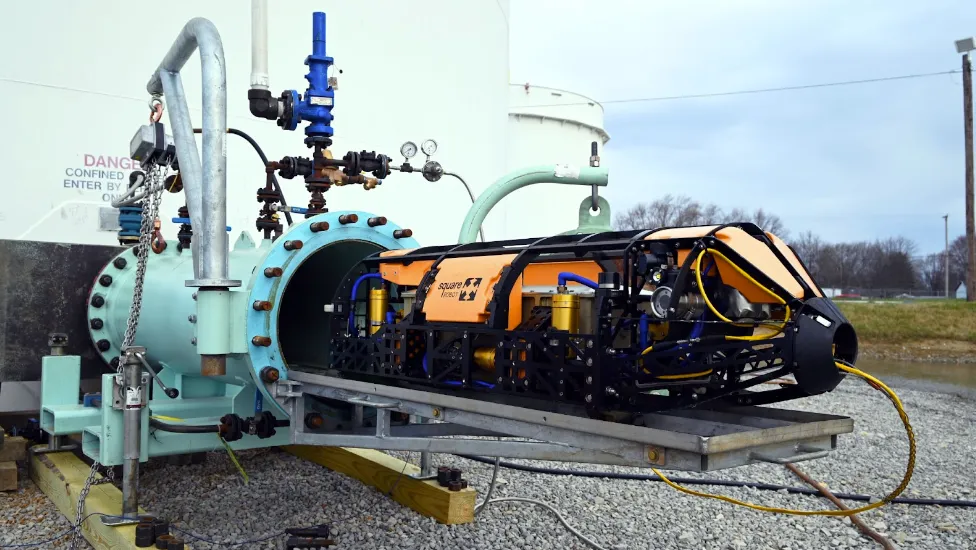

One of the most striking aspects of this solution is its ability to operate with a full tank. The fully submersible robot is introduced through a 24-inch opening, either from the top or side, without the need to remove the tank from service. This eliminates traditional processes such as emptying, degassing and manual cleaning, which involve high costs and risks.

Once inside, the robot collects data by means of phased array ultrasonics with 256 elements, covering the entire surface of the tank bottom. It also generates visual images and settlement analysis, providing a detailed and continuous view of the internal structural condition.

This technology allows for the collection and delivery of large volumes of information(up to 1 terabyte per inspection) with higher accuracy than conventional methods such as MFL or SPOT-UT. The data is easily integrated into the client's systems for real-time analysis, facilitating more agile and accurate decision making.

Thanks to this approach, companies can schedule predictive maintenance and optimize the planning of technical shutdowns, which translates into greater operational continuity and reduced costs.

Although the robot is designed to work in a wide range of products, from water and diesel to gasoline or styrene, there are conditions that can affect its performance. One of the main ones is the level of sediment inside the tank: if there is more than 3 to 4 inches of sludge, the accuracy of the ultrasound is reduced.

Another important aspect is the size of the manway. Square Robot requires a minimum diameter of 24 inches to enter the equipment, which in some cases has led operators to modify their tanks to make its use viable.

Square Robot demonstrates that practical innovation can solve long-standing operational problems. Its participation in NISTM 2025 highlights the company's position as a benchmark in robotic solutions for tank inspection, with a sound technical approach aligned with the new demands of the energy and industrial sector.

For more content about NISTM 2025, please visit our LinkedIn profile.

Source: Inspenet.