During the PANNDT Conference in Niagara Falls, the Sonatest team stood out for its presence and its cutting-edge technological approach. In an exclusive interview, Philippe Rioux, Equipment Leader and Applications Specialist, shared the advances that are transforming the ultrasonic inspection, especially as it relates to connectivity, data automation and the future use of artificial intelligence. His participation shed light on the company's commitment to innovation in non-destructive testing (NDT), reaffirming its position as a reference in the industry.

The digitization of NDT is advancing rapidly and Sonatest is knowing how to adapt with agility, which translates into instruments that integrate state-of-the-art hardware and software. Such is the case of the WAVE system, which allows full remote control using Python code and offers real-time data transmission functionalities, opening the door to new communication scenarios, such as rope access and augmented reality environments.

Although the full integration of artificial intelligence is still in the development stage, Rioux says it is already part of the strategic plan. In his vision, AI will not replace the operator, but will be an ally that will strengthen decision-making on the integrity of inspected assets.

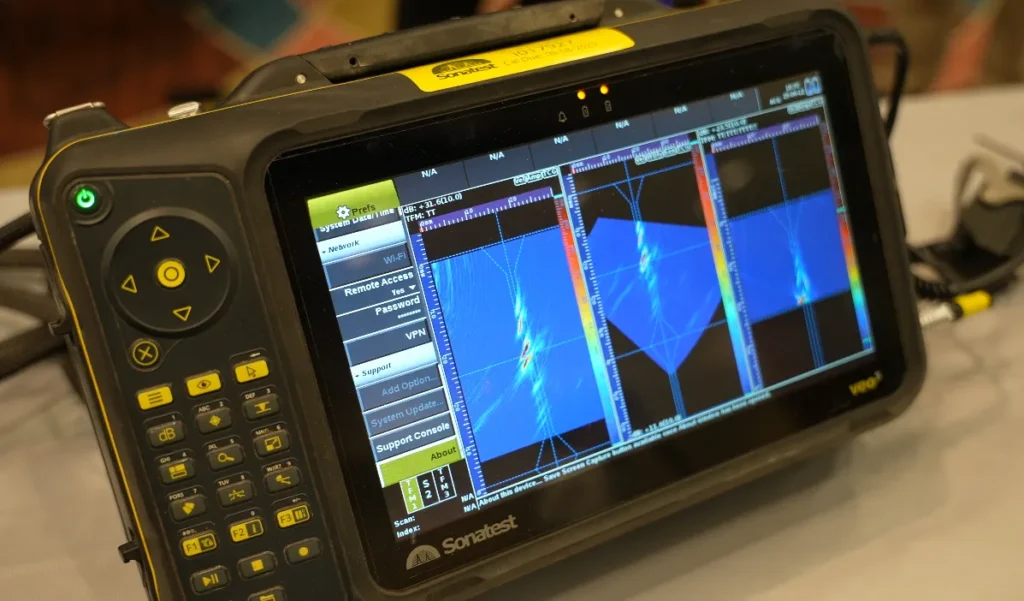

The evolution of ultrasonic inspection techniques, such as Full Matrix Capture (FMC) and Total Focusing Method (TFM), has enabled Sonatest to offer higher geometric fidelity and better defect characterization. Devices such as the Veo3 combine these methods with features such as ISCAN, generating high resolution images that allow the technician to compare, validate and report with confidence.

The ability to capture advanced data, integrate it with previous information and generate detailed reports reduces interpretation errors and improves operational safety, paving the way for future machine learning applications within the enterprise ecosystem.

With a presence at major industry events such as ASNT and PANNDT, the company also stands out for its user-focused approach, cemented by a mature network of international distributors who channel users' queries and needs to its technical team.

The commitment to training is reflected in the continuous production of videos, seminars and training materials available to customers, facilitating the adoption of complex technologies even in regions or sectors that are just starting to use advanced UT.

The company's formative approach has also contributed to maintaining long-term relationships with its customers and, according to Rioux, they continue to rely on its solutions after years of collaboration, thanks to proactive technical support and a carefully crafted user experience.

With more than six decades of history, Sonatest has been a part of the growth of the NDT sector from its earliest stages. Their headquarters in the UK has allowed them to connect with major markets in Europe, America and Asia, positioning them as a trusted supplier to industries such as aerospace, petrochemical, rail and manufacturing.

Endorsements from customers such as Shell, Airbus, Siemens and ArcelorMittal attest to the quality of its equipment and its reliability in demanding environments. Equipment such as WAVE, Prisma and RSflite have gained recognition for their ease of use and ability to deliver consistent results in complex inspection applications.

The interview with Philippe Rioux makes it clear that ultrasonic inspection is entering a new era. Backed by more than 60 years of experience, Sonatest commitment to artificial intelligence, total connectivity and user-centered design offers an encouraging outlook for the nondestructive testing industry.

For more content on PANNDT 2025, visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.