During his participation at NISTM 2025, Brian Howsare, IMS International Business Development Manager at Endress+Hauser, detailed how the company is addressing today's challenges in industrial tank management. In his talk, he presented a software solution designed to improve accuracy, operational control and tax compliance in facilities that store large volumes of product.

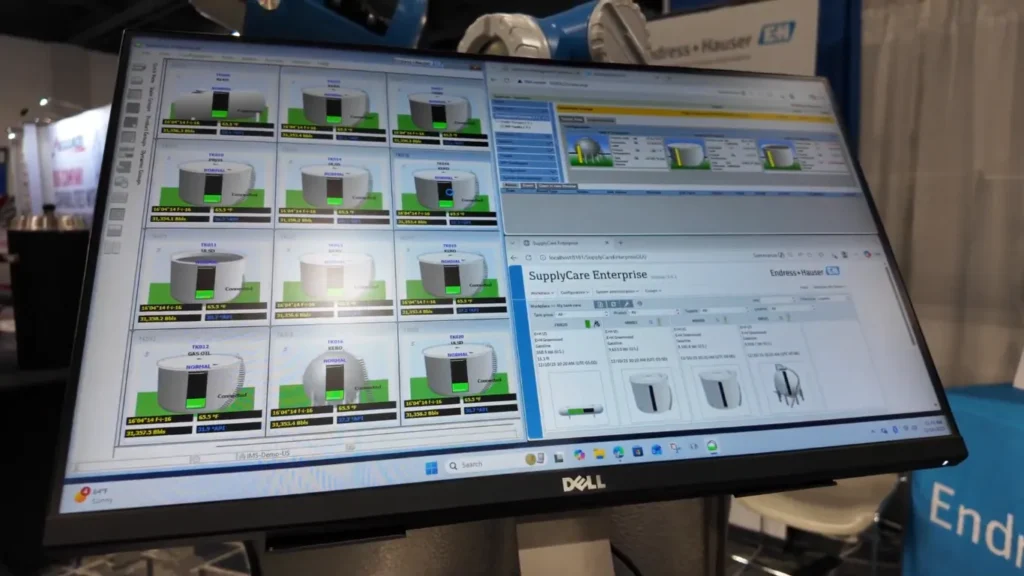

The company unveiled a complete tank gauging system that combines radar sensors, servomechanisms, and temperature and pressure technologies. These elements work together to provide accurate data on product level, internal temperature and ambient pressure. In addition, it can detect unwanted water at the bottom of tanks and provide a density profile, an essential functionality in industries such as petrochemicals and fuels.

According to Howsare, not all devices suit all applications, so Endress+Hauser offers a diverse range of technologies that can be configured to each customer's specific requirements.

Its software also enables detailed reports and alarms to be generated, for example, in the event of overfilling. These elements are integrated into the plant's operational control and, at the same time, play a role in accounting and taxation by facilitating the monitoring of losses due to evaporation, thermal contraction and other factors.

Thanks to this real-time information, plant managers can make more technically based decisions, thus optimizing inventory planning, storage efficiency and operational safety.

One of the outstanding features of this solution is its scalability; Endress+Hauser offers a "Tank Gauging in a Box" system that can control up to 15 tanks per unit. As needs grow, modules can be added to cover

Regarding its use, Howsare assured that the platform is designed so that new users can become familiar with it in a few hours, thanks to training included in the start-up stage.

Endress+Hauser is recognized worldwide for developing measurement and automation technology for industrial processes. Its focus is on building long-term relationships with its customers through robust, reliable and adaptable solutions.

With its advanced measurement system, Endress+Hauser reinforces its position as a strategic partner for industries requiring critical measurement technology, reaffirming its role as a reliable supplier in an increasingly automated and demanding environment.

For more content about NISTM 2025, please visit our LinkedIn profile.

Source: Inspenet.