During the NISTM 2025 event, Agellus Tank Robotics captured attention with its ATR 360 solution, a robotic system designed to perform aboveground storage tank (AST) inspection tasks without interrupting operation. Damien Goodyear, co-founder and vice president of operations, explained how this technology transforms traditional maintenance and inspection practices.

The ATR 360 is an autonomous robotic system developed to inspect industrial tanks while they are in operation. Its purpose is to eliminate human entry into

The ATR 360 underwater robot is equipped with 256-channel phased array UT technology, allowing it to perform detailed scans of the tank floor and detect structural defects with high precision. Furthermore, it is designed to operate in hazardous environments (HazLoc), with corrosion-resistant and explosion-proof materials.

The system includes cleaning, analysis and monitoring modules, making it a comprehensive platform for tank inspection. Its ability to adapt to different types of tanks makes it especially versatile for large-scale industrial installations.

The use of the ATR 360 allows keeping the tanks in operation during inspections, reducing downtime costs and avoiding emptying processes, representing a direct improvement in operational efficiency.

In terms of safety, the system prevents personnel from entering confined spaces, which significantly reduces the risks associated with hazardous atmospheres. In addition, the ability to perform periodic inspections also allows the implementation of predictive maintenance strategies.

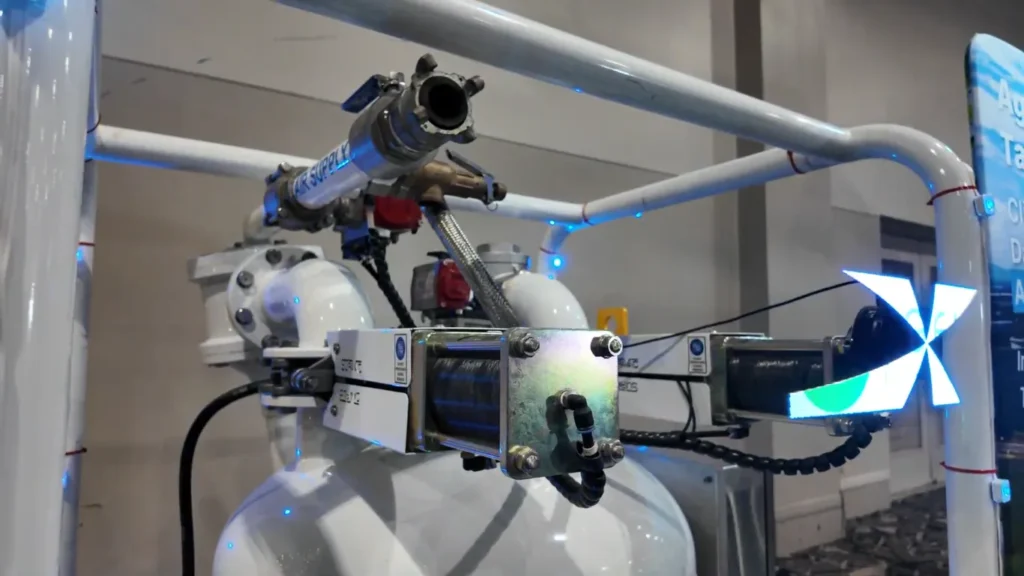

At the Agellus booth, attendees were able to observe a real ATR 360 unit, which was mounted on a demonstration structure that included pneumatic components, sensors and visible industrial connectors.

This physical exhibition made it possible to appreciate the applicability of the ATR system and its level of technological maturity, generating interest among engineers, operators and decision-makers in the sector.

Tank inspection is a critical activity in the energy and industrial industry. Solutions such as the

For more content about NISTM 2025, please visit our LinkedIn profile.

Source: Inspenet.